- May 2, 2018

- 181

- Pool Size

- 20000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- CircuPool Edge-40

Wait until you see my v2!Nice, you always manage to find the best looking stuff, including the DIN rail mounts.

Wait until you see my v2!Nice, you always manage to find the best looking stuff, including the DIN rail mounts.

I have the usb to rs485 adapter...and the cable that came with the Intelliflo. Not quite sure how to connect those two devices. Once I figure that out, I have nodejs-poolController installed on my Pi, so can start playing with it.Nice. I'm waiting for my pump to die so I can pick up an Intelliflo. The RS-485 adapters to interface the pump with a pi start as low as 6.99 on amazon. So it's pretty cheap to get into experimenting with nodejs-poolController. That would also allow you much more control over your pump vs just using the relay speed settings.

I've started keeping my flows on github.

I have the usb to rs485 adapter...and the cable that came with the Intelliflo. Not quite sure how to connect those two devices. Once I figure that out, I have nodejs-poolController installed on my Pi, so can start playing with it.

If anyone has any pointers on nodes-poolController, I would love to hear them. I've read all I can but some of the notes from the GitHub are a bit over my head. Would love to find a tutorial somewhere.

I don't have an intelliflo yet but it doesn't look too bad. The RS-485 cable is two wires. Should plug into the two ports on the adapter pi adapter. Then you start the nodejs software with npm start. Then you go to http://yourpiaddress:3000 and you should get a web menu and if all was done right you should have a web page with some info on your pump in it.

I'd check the logs first. Or the console. When you run it by hand it should put the output to the console.I hooked up my pump to the rs-485 adapter, but am getting nothing via serial, so not really sure what to do to troubleshoot. The web address above populates, but there is no data and it says "never" in the last connection. Wondering if it's possible I got a bad usb to serial converter?

I’m getting the exact same response. However, I do have an intelliflo lol. I’m not getting anything from the console but do see the serial adapter being recognized by the pi. Wasn’t able to get anything from my Mac either, so I’m wondering if my adapter isn’t working or possibly some other user error.I'd check the logs first. Or the console. When you run it by hand it should put the output to the console.

I'm assuming you're running from 'npm start' Are you getting any errors? I get this:

21:20:12.041 INFO Your version (5.3.0) is the same as the latest published release.

21:21:11.086 INFO Serial port recovering from lost connection.

Because I don't have an intelliflo.

I found this manual. Looks like yellow is +, green is -. You want to hook up while power is killed to the pump.I’m getting the exact same response. However, I do have an intelliflo lol. I’m not getting anything from the console but do see the serial adapter being recognized by the pi. Wasn’t able to get anything from my Mac either, so I’m wondering if my adapter isn’t working or possibly some other user error.

I also just checked over at the nodejs-poolcontroller gitter space. The very last question by someone was how to hook it up.. Here was their responseI’m getting the exact same response. However, I do have an intelliflo lol. I’m not getting anything from the console but do see the serial adapter being recognized by the pi. Wasn’t able to get anything from my Mac either, so I’m wondering if my adapter isn’t working or possibly some other user error.

Thanks! Check out @jonpcar build too. His UI interface is beautiful and he's got some really cool things going on with meters for chlorine and acid levels too. Also, @segalion is doing one too. And @Katodude is just starting on his. We really should have a sticky with all the DIY projects in here!Wow, this is a fantastic project, congrats! I'm living vicariously through this post as I can't get my wife to let me mess with the old Jandy system I installed 5 years ago. I'd love to try something similar with esp 32.

Keep up the great work!

Chris

I’ve done all that but I did hook up the adapter while the pump was running. What is the consequence of that?I found this manual. Looks like yellow is +, green is -. You want to hook up while power is killed to the pump.

I also found this statement:

Note: For the IntelliFlo VS+ SVRS to accept commands from IntelliComm, the pump must be in the “Running Schedules” mode (LED above the Start/Stop button lit).

If you've done all that then... ?

Manual says it should be off. That’d be awesome if that’s all it is!I’ve done all that but I did hook up the adapter while the pump was running. What is the consequence of that?

Where is this manual you speak of? I've had a struggle finding some good instructions on how to get this working. I plan to shut the pump down and try again in the morning.Manual says it should be off. That’d be awesome if that’s all it is!

It's for an SVRS but I suspect they're same. It's hereWhere is this manual you speak of? I've had a struggle finding some good instructions on how to get this working. I plan to shut the pump down and try again in the morning.

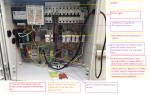

4. I decided that despite my children being complete and utter turds sometimes, I love them. I recently read a news story (WARNING! SAD!) about a girl who got electrocuted by pool lights. So I decided I'd add a GFCI to the circuit that goes to my lights to protect my cute little investments. (Seriously, they're gonna grow up and support me, since my first two didn't...). It was a major PITA to find a 240v DIN rail GFCI circuit breaker but I managed to do so. It's not the same style (UL439 vs UL1077) as the rest of my breakers though. To maintain the busbar system, I will have to replace them all and UL439 breakers are double the cost of UL1077 breakers but I'll do it because they're worth it.

I don't think you could do that. The problem is they have to both trip at the same time. That's why the 240v breakers are always tied together. There may be some other innards that are related to that. I don't think this would be a good idea.Hmm, this gives an idea. I have two GFCI 120v circuit breakers. Would it make sense to wire each side of the hot 240v entrance with one of the breakers?

Hi Cliff, @cmc0619

I may have missed it in your posts, but would you mind linking what 120 and 240 relays you are using. I've looked all over Automation direct and have found a very large variety of relays but haven't found the ones that seem to look the same visually. Just trying to make sure I'm not missing something and if there is a specific reason you picked the ones you did. i.e. slim, or other feature.

My plan is to control the larger relays with a Pi HAT relay board (still deciding there too). Just for the SWG and heater.

Sure thing! They're the 782 model. Socket, relays, and MOVs for relay protection when switching inductive loads.

I picked them because they were rated for 15Amps. If/when I get my Intelliflo I'll have to head into contactor territory

For lower currents and to save rail space you can also use the slim relays. You can use these jumper poles to link common wires to reduce wiring as well. I probably should've used these for my pool lights instead of the 782s but I guess there's something to be said for keeping everything the same as well. If you're really tight on space I found a dual slim relay as well. I picked one up. It's pretty tall so didn't use it.

A few of us are using the Sequent Microsystems board (on sale here) with good success. I've looked far and wide and have yet to find anything else with 8 relays in a hat format.