pikeman

Well-known member

Installed new shoes on the Navigator pool cleaner. Worked wonders on its performance! Tomorrow it’s finally time to get in the water. It’s up to 76.

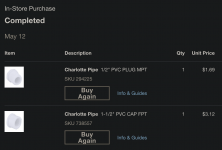

Quick question for maybe others to learn as well. Did you use a standard 1 1/2 inch threaded cap (like from HD)?After dealing with months of the stupid inline chlorinator having a small drip I finally looked underneath it and noticed the freakin' thing SCREWS ONTO THE TEE. This entire time I thought it was all cemented together, the tee and everything. Boy was I confused. Anyway, I corrected that problem, and I reinstalled the chlorinator in a much better place.

I stumble onto plumbing YouTubes now and then and watch them. I see them using tape and some sort of dope on PVC now (both, together). I started doing that with my metal plumbing connections a while back, even though I used to swear it was only supposed to be one or the other. But I kept getting drips that were then completely cured by using both. And apparently some plumbers are using both for PVC threads as well. I just don't know what kind of dope to use on PVC...Quick question for maybe others to learn as well. Did you use a standard 1 1/2 inch threaded cap (like from HD)?

I did try that with mine but it had a small leak and I even tried to use a oring in there to help seal. I had the Pentair 320 chlorinator. Just curious what you did or maybe show a picture of the parts before you installed it.

I eventually removed the whole tee when I installed the SWCG.

I stumble onto plumbing YouTubes now and then and watch them. I see them using tape and some sort of dope on PVC now (both, together). I started doing that with my metal plumbing connections a while back, even though I used to swear it was only supposed to be one or the other. But I kept getting drips that were then completely cured by using both. And apparently some plumbers are using both for PVC threads as well. I just don't know what kind of dope to use on PVC...

Very refreshing! Given how sweaty I was, I probably need to dial up the SWCG.

Very refreshing! Given how sweaty I was, I probably need to dial up the SWCG. Quick question for maybe others to learn as well. Did you use a standard 1 1/2 inch threaded cap (like from HD)?

I did try that with mine but it had a small leak and I even tried to use a oring in there to help seal. I had the Pentair 320 chlorinator. Just curious what you did or maybe show a picture of the parts before you installed it.

I eventually removed the whole tee when I installed the SWCG.

Huh, according to this you don't, but that's news to me. What about PVC male into brass female? (That's where I used tape and dope.)Apparently you're not supposed to use tape as this can lubricate the joint?

Apparently you're not supposed to use tape as this can lubricate the joint?

The more you know. I thought it was to prevent leaks

Is the fear that the tape will allow you to apply so much force that you crack the fitting?

Words about pvc and threads