I want to thank each and every one of you for taking the time to help me troubleshoot the issue with my control panel. It has become obvious that my control panel is beyond dated and needs to be replaced. I ordered a new panel today. Time for a fresh start. I inherited a SWG system that was ill conceived and not well maintained. It's been a time consuming and expensive process updating the previous system as well as milking the extra life out of it. I'm betting, however, this will not be the last you'll hear from me. TFP is far too great of a resource, and I continue to learn a lot.

Replace 3-Prong Pool Motor Outlet

- Thread starter lplatz

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Jul 21, 2013

- 53,955

- Pool Size

- 35000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

- Jul 21, 2013

- 53,955

- Pool Size

- 35000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

What are you going to do about your pump that pulls 15 amps which is too much for that outlet?

Using that pump will burn out the outlet and board again.

You need a pump that pulls 12amps or less to use the outlet.

Using that pump will burn out the outlet and board again.

You need a pump that pulls 12amps or less to use the outlet.

It's on my short to-do list. I'll check to see if the existing motor (which fits the pump housing) comes in a 12amp version. I believe the other suggestion was to step down to 1 hp motor. Current motor is a Sta-Rite Dynamo.

- Jul 21, 2013

- 53,955

- Pool Size

- 35000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

If you downsize the motor you must downsize the impeller.It's on my short to-do list. I'll check to see if the existing motor (which fits the pump housing) comes in a 12amp version. I believe the other suggestion was to step down to 1 hp motor. Current motor is a Sta-Rite Dynamo.

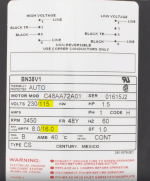

A new pool pump motor is on the way. Century (A.O. Smith) 1.5 HP model BN35V1. Ordered from INYO Pools. All just in time to close the pool down for the season. Thanks again ajw22 for all your help with my pool issue. Greatly appreciated. Looking forward to a trouble-free pool in 2024.

One last question. I'm assuming I'll need to jump the J4 pads to use the T-15-Cell correct?

- Jul 21, 2013

- 53,955

- Pool Size

- 35000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

Yup.One last question. I'm assuming I'll need to jump the J4 pads to use the T-15-Cell correct?

- Dec 13, 2020

- 780

- Pool Size

- 19600

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Jandy Aquapure 1400

In addition to @ajw22's concerns about controls burning up, it would also be good to verify the upstream breaker is at least 20 amps.

Too late now, but another tool in the kit for stuff like this is to drive a 20A or bigger relay with the one that's too weak, and use the relay to control the motor. This also allows the motor to have its own 20A circuit, if one can be provided.

Too late now, but another tool in the kit for stuff like this is to drive a 20A or bigger relay with the one that's too weak, and use the relay to control the motor. This also allows the motor to have its own 20A circuit, if one can be provided.

Upstream breaker is 20 amp. This breaker is primarily dedicated to the control panel which provides the power to the pool pump motor. I should be solid on my electrical. I greatly appreciate your input. Had I not had this forum's input, I would have installed the equipment "as-is" and would be facing this same issue in another year or possibly less.In addition to @ajw22's concerns about controls burning up, it would also be good to verify the upstream breaker is at least 20 amps.

Too late now, but another tool in the kit for stuff like this is to drive a 20A or bigger relay with the one that's too weak, and use the relay to control the motor. This also allows the motor to have its own 20A circuit, if one can be provided.

I am unfortunately back with further issues. This is beyond frustrating at this point. I received my updated Hayward W3AQ-TROL-RJ-TL panel just over 30 days ago. Shortly thereafter, I also received my new motor for my pool pump. I decided to install the new motor first. No biggie until I plugged in the motor. I've attached a short video of what happened (

). I contacted the seller to troubleshoot (INYO Pools). They came to the conclusion that the motor was bad and suggested I send it back for a replacement. It turned out that since it was bad, I had to go through a warranty return process which delayed my getting a replacement motor. It finally arrived last week. I installed it this evening and same thing happened. The video is actually from this evening after install. It acted the same after both installations. I seriously don't believe the motor is faulty. The odds of that are too great.

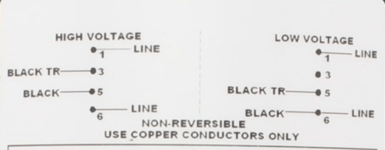

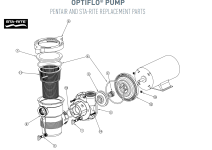

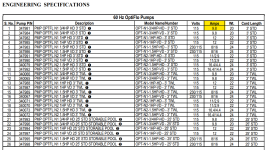

I apologize for the lengthy post, please hang in there. The information I need to share should eliminate a lot of follow up questions. Regarding the motor. When I ordered the motor, I requested a 12 amp motor due to the mother board running hot and burning through the power leads to the circuit board. That suggestion (lower amp motor) came from TFP forum. The motor they hooked me up with could do either 8 or 16 amps (spec sheet attached). I verified with INYO it would work with my Pentair Optiflo Pump. I was assured it would. I also advised them it would be hooked up to a Hayward AQ-TROL-RJ Saltwater Control Panel. They confirmed this was the correct motor. Any ideas what would cause a motor to cycle on/off like this?

One additional nugget of information. The motor ran fine prior to installation into the pump housing.

I apologize for the lengthy post, please hang in there. The information I need to share should eliminate a lot of follow up questions. Regarding the motor. When I ordered the motor, I requested a 12 amp motor due to the mother board running hot and burning through the power leads to the circuit board. That suggestion (lower amp motor) came from TFP forum. The motor they hooked me up with could do either 8 or 16 amps (spec sheet attached). I verified with INYO it would work with my Pentair Optiflo Pump. I was assured it would. I also advised them it would be hooked up to a Hayward AQ-TROL-RJ Saltwater Control Panel. They confirmed this was the correct motor. Any ideas what would cause a motor to cycle on/off like this?

One additional nugget of information. The motor ran fine prior to installation into the pump housing.

Attachments

- Jul 21, 2013

- 53,955

- Pool Size

- 35000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

Show us how you wired that motor.

That motor only pulls 8 amps if you wire it for 240V. Your Aquatrol plug is 120V and that motor will pull 16 amps and burn out your Aquatrol again.

That motor only pulls 8 amps if you wire it for 240V. Your Aquatrol plug is 120V and that motor will pull 16 amps and burn out your Aquatrol again.

Last edited:

Looks like you have the wrong voltage.

The pump comes wired for 240 volts.

If you supply 120 volts and it is wired for 240 volts, it will not work correctly.

The pump comes wired for 240 volts.

If you supply 120 volts and it is wired for 240 volts, it will not work correctly.

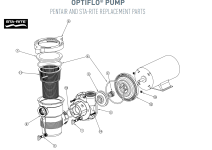

Which impeller do you have?

You can see the impeller part number inside the impeller.

What is the model number of the pump.

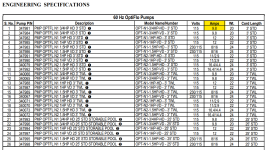

Replace the impeller to drop the amps to about 9.8 or lower.

354552 Impeller 3/4 hp

www.inyopools.com

www.inyopools.com

www.inyopools.com

www.inyopools.com

You can see the impeller part number inside the impeller.

What is the model number of the pump.

Replace the impeller to drop the amps to about 9.8 or lower.

354552 Impeller 3/4 hp

Pentair Impeller for 3/4 HP Dynamo Pool Pump - 354552 - INYOPools.com

354552 - IMPELLER, 3/4 HP DYNAMO (354552)

Pentair Optiflo Pump - 3/4 to 1 1/2 HP Parts - INYOPools.com

Pentair Optiflo Pump - 3/4 to 1 1/2 HP - INYOpools.com has the largest selection of swimming pool and spa replacement parts with over 70,000 parts in stock. Order today and save!

Attachments

Do you guys ever rest!? THANK YOU for your quick response. In reading your solutions, it sounds like I can keep the motor, just wire if for low voltage (currently wired for high voltage). I'll do that tomorrow. Regarding the replacement impeller. You suggested the 3/4 HP Dynamo. Reading your chart, that will lower the amp to 9.8. Back in October 11, ajw22 advised that I needed the amps to be at 12 or below to fit my Hayward W3AQ-TROL-RJ-TL control panel. Given that, could I install the 1 HP impeller. Your chart shows that with the 1 HP impeller the motor amp would be 12. If given the choice to choose between the two (and both would work) what are the benefits of a higher or lower HP impeller?

If you are 100% sure that the voltage is 120, change the wiring to the low voltage configuration.

If the voltage is 240 and you change it to the low voltage configuration, you will destroy the motor.

In my opinion, the 3/4 hp impeller will be more than enough.

If anything, it is still too much.

If there was a smaller impeller, I would use the smaller impeller.

If the voltage is 240 and you change it to the low voltage configuration, you will destroy the motor.

In my opinion, the 3/4 hp impeller will be more than enough.

If anything, it is still too much.

If there was a smaller impeller, I would use the smaller impeller.

People think that if the power is half, then the flow will be half, but that is not how it works.

At half the power, the flow is about 80% of the original flow.

So, if the flow was 60 at 1.5 hp, the flow at 3/4 hp will be about 48 gpm.

The flow with the 3/4 hp impeller will be plenty and it will cut the cost of electricity by almost half.

At half the power, the flow is about 80% of the original flow.

So, if the flow was 60 at 1.5 hp, the flow at 3/4 hp will be about 48 gpm.

The flow with the 3/4 hp impeller will be plenty and it will cut the cost of electricity by almost half.

Thread Status

Hello , This thread has been inactive for over 60 days. New postings here are unlikely to be seen or responded to by other members. For better visibility, consider Starting A New Thread.