Sorry to revive the old thread but I am trying to do what you did and could really use assistance. I only have one open relay on my board, will need to buy one, and would love to understand how the panel used/supports a dual speed on a single relay or was that a separate/special relay that jandy makes to support 2 speeds. My spa vales kick over automatically in spa mode and want to keep all of that working and follow the VSP rules of being always on.I described the setup in some detail here:

Please critique my Variable-Speed Pump Upgrade Plans (including iAqualink Integration)

With my electric rates expected to skyrocket once my contract runs out early next year, I've fast-tracked my plans to upgrade my main filter pump to a variable-speed unit. I currently have a single-speed 1.5 hp pump controlled by a Jandy iAqualink 2.0 system (other details of my system as...www.troublefreepool.com

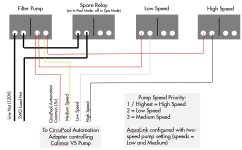

Also attached a wiring diagram of how I setup the relays. Hope this helps.

Moved from here.

Last edited by a moderator: