| Line 31: | Line 31: | ||

==Automation Control== | ==Automation Control== | ||

| − | The JXI | + | The JXI heater can be controlled by Jandy Aqualink or other automation systems. |

| + | |||

| + | Connect using a 2-wire connection if your Aqualink RS PCB firmware is REV MMM or earlier or if you are connecting to another automation system. | ||

| + | |||

| + | Connect using the RS485 connection if your Aqualink RS PCB firmware is REV N or higher. All AquaLink Infinity Firmware | ||

| + | revisions are RS485 ready. For details, see Section 7.3 in the JXI Installation Manual, “Smart” Communication via RS-485. Aqualink PDA System with firmware revision 4.1 or higher is required to support the RS-485 heater interface. | ||

| + | |||

| + | Aqualink RS PCB Rev MMM or earlier has one red 4-wire RS-485 connector, JVA sockets on the top of the board, and 10 high-voltage relay sockets—eight on the bottom and two on top. | ||

| + | |||

| + | Aqualink RS PCB Rev N or later has two red 4-wire RS-485 connectors, JVA sockets on the bottom of the board, and 11 high-voltage relay sockets—all on the bottom. | ||

| + | |||

| + | ===2-Wire Control Configuration=== | ||

| + | |||

| + | Remote TSAT control must be enabled on the JXI control panel by: | ||

| + | *Make sure the pool heater is OFF. | ||

| + | *Press and hold MENU, then the POOL and SPA buttons for 5 seconds to access Service Setup mode. | ||

| + | *NOTE: The display will revert to OFF 1 minute after the last key press. | ||

| + | *Press MENU, REMOTE OFF (default) is displayed. | ||

| + | *Use Up or Down to scroll through the Remote options until REMOTE TSTAT is displayed, then press MENU to select. | ||

| + | *Press POOL or SPA to exit Service Setup mode. | ||

| + | *Press POOL or SPA to adjust the set point to the maximum 104°F (40°C). | ||

| + | |||

| + | ===RS-485 Control Configuration=== | ||

| + | |||

| + | *Use 22 gauge 4-conductor wire to run between the heater and the control system and match the wire color order. | ||

| + | *The wires coming from the heater can be “doubled up” on the red RS485 terminal bar with the four wires from other devices. | ||

| + | *Do not connect more than two (2) wires to any of the terminals in the Control System when connecting peripheral devices. If connecting the heater to the control system creates this situation, then a Multiplex PCB Kit, which includes the Multiplex Board (part # 6584) must be used. | ||

| + | |||

| + | When the heater is connected to an external controller, all functionality of the heater control panel is disabled, | ||

| + | therefore heater functions can be controlled only from the controller. Control can be restored to the local | ||

| + | heater control panel by disconnecting the red RS485 terminal or entering the service setup mode selecting REMOTE then STANDALONE. Control can be sent back to the external controller by re-entering the service setup mode and selecting JANDY RS485, unplugging and replugging the RS485 connector, or by cycling power to the heater with the RS485 control cable connected. | ||

==High Altitude== | ==High Altitude== | ||

Revision as of 01:09, 21 December 2024

Jandy JXI Heaters

Jandy LXI Heaters is the prior model that shares much in common and may also have helpful information.

You will find the model number and serial number on the heater rating plate located on the front of the combustion chamber. Remove the heater front panel to view the combustion chamber.

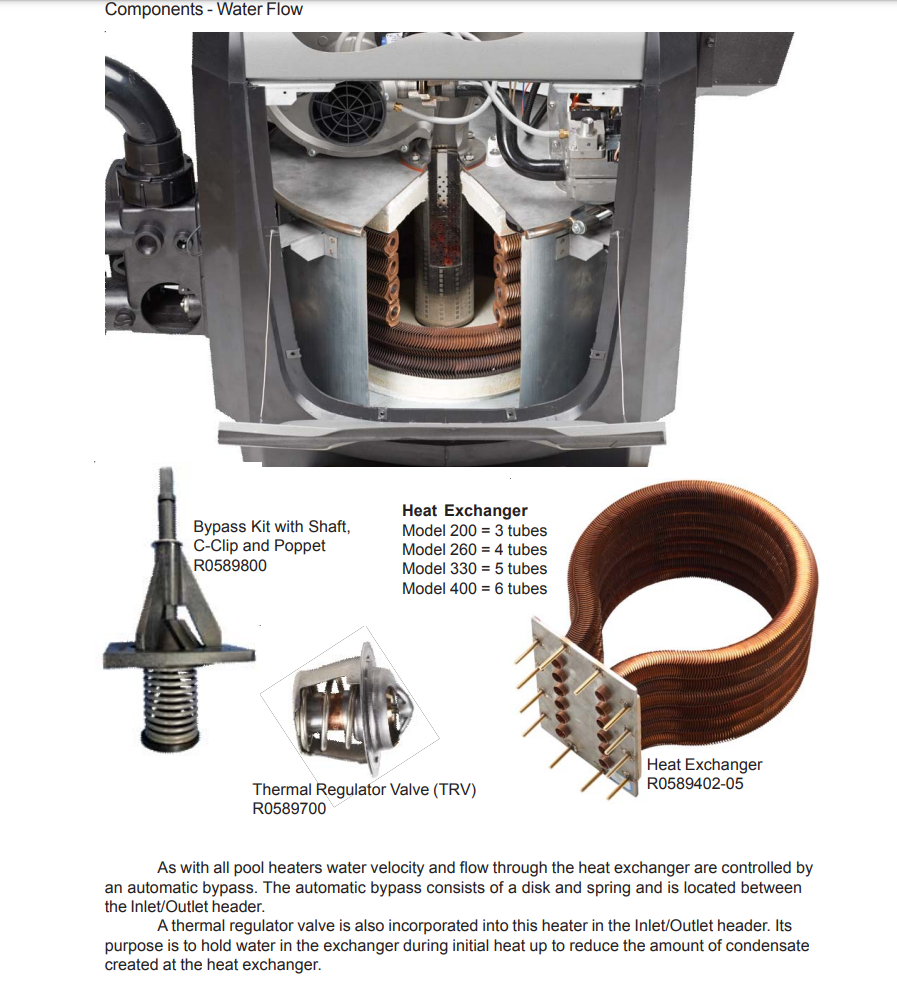

Jandy JXI models are 200, 260, 330, and 400 BTU heaters for natural gas or propane. Options on the heaters are the VersaFlo automatic bypass or ASME bronze headers with thicker-walled, integral copper fin tubes.

The heaters have a thermal efficiency of 83%-84% and require a minimum flow of 30 GPM and maximum flow of 100 GPM.

JXi with VersaFlo activates the built-in flow bypass valve based on call for heat to avoid running water through the heat exchanger when water does not need to be heated. JXi heaters with VersaFlo factory installed receive a 5-Year standard warranty on the heat exchanger.

Sequence of Operation

- The control system reads the temperature of the water

- Start-up process begins if the temperature is below the set point

- Blower starts, then adequate airflow is confirmed by the air pressure switch

- After airflow is confirmed, the ignition sequence begins

- After a 15-second purge, the igniter gets power

- After approximately 40 seconds of igniter heat up, power is sent to the gas valve

- The gas valve remains open for 5 seconds while the Ignition Control is looking for flame rectification

- As long as flame is sensed at the burner, operation continues until the temperature of the water entering the heater reaches the temperature control setting.

The JXI heater does not have a pilot light. It is equipped with an ignition device which automatically lights the burner. DO NOT try to light the burners by hand.

The blower pushes the air gas mixture into the flame holder inside the sealed combustion chamber.

Automation Control

The JXI heater can be controlled by Jandy Aqualink or other automation systems.

Connect using a 2-wire connection if your Aqualink RS PCB firmware is REV MMM or earlier or if you are connecting to another automation system.

Connect using the RS485 connection if your Aqualink RS PCB firmware is REV N or higher. All AquaLink Infinity Firmware revisions are RS485 ready. For details, see Section 7.3 in the JXI Installation Manual, “Smart” Communication via RS-485. Aqualink PDA System with firmware revision 4.1 or higher is required to support the RS-485 heater interface.

Aqualink RS PCB Rev MMM or earlier has one red 4-wire RS-485 connector, JVA sockets on the top of the board, and 10 high-voltage relay sockets—eight on the bottom and two on top.

Aqualink RS PCB Rev N or later has two red 4-wire RS-485 connectors, JVA sockets on the bottom of the board, and 11 high-voltage relay sockets—all on the bottom.

2-Wire Control Configuration

Remote TSAT control must be enabled on the JXI control panel by:

- Make sure the pool heater is OFF.

- Press and hold MENU, then the POOL and SPA buttons for 5 seconds to access Service Setup mode.

- NOTE: The display will revert to OFF 1 minute after the last key press.

- Press MENU, REMOTE OFF (default) is displayed.

- Use Up or Down to scroll through the Remote options until REMOTE TSTAT is displayed, then press MENU to select.

- Press POOL or SPA to exit Service Setup mode.

- Press POOL or SPA to adjust the set point to the maximum 104°F (40°C).

RS-485 Control Configuration

- Use 22 gauge 4-conductor wire to run between the heater and the control system and match the wire color order.

- The wires coming from the heater can be “doubled up” on the red RS485 terminal bar with the four wires from other devices.

- Do not connect more than two (2) wires to any of the terminals in the Control System when connecting peripheral devices. If connecting the heater to the control system creates this situation, then a Multiplex PCB Kit, which includes the Multiplex Board (part # 6584) must be used.

When the heater is connected to an external controller, all functionality of the heater control panel is disabled, therefore heater functions can be controlled only from the controller. Control can be restored to the local heater control panel by disconnecting the red RS485 terminal or entering the service setup mode selecting REMOTE then STANDALONE. Control can be sent back to the external controller by re-entering the service setup mode and selecting JANDY RS485, unplugging and replugging the RS485 connector, or by cycling power to the heater with the RS485 control cable connected.

High Altitude

Appliances are normally derated when installed at high elevations. This is not necessary with the JXi heater because it has a special venturi-type combustion system that self-compensates for changes in barometric pressure. Airflow through the blower inlet pulls the correct flow of gas into the burner regardless of air density.

JXi heaters are CSA certified for elevations up to 4,500 feet above sea level. At elevations above 4,500 ft., the heater BTU output can be expected to be reduced by 4% for every 1,000 feet above sea level.

JXI Head Loss and Flow

Repairs

Workbook JXi Pool&Spa Heater is a training manual for pool repairmen.

Industrial Electronic Repair has repaired Jandy heater boards. Check with them if your board needs replacement.[1]

JXI Igniters

Silicon Carbide Hot Surface Ignitors are very fragile. That is why they come packed in thick foam packaging. After removing be sure not to bump, scrape or jar the black crystalline part of the ignitor. Also be sure not to touch or contaminate the black crystalline surface with your hands ( it can cause it to fail very similar to a halogen bulb that has been touched with your hands). Although these are not the only reasons for a hot surface ignitor to fail, they are basic precautions that need to be adhered to.

After installing check the resistance of the ignitor with a multimeter. A new ignitor should read approximately 40-90 ohms.[2]

Jandy changed the igniter style a while back as the ones they originally used broke too easily. The old one was like a spiral design.

The new style is more of a solid looking piece.[3]

Flame Rectification Failure

Does the heater briefly ignite, producing a puff of heat before shutting down? If so, you may have a flame-sensing problem. Heater Flame Sensing describes what may be happening and offers ways to fix it.

The flame is sensed through the igniter to the ground. You need to ensure that all the grounding connections, screws, wires, and wiring terminals are clean to get a good flame signal.

The ignition control provides 120v to the igniter, and after a specified time, the ignition drops out the 120v to the igniter, looking for proof of flame through a different circuit.

After the ignition cycles, it fails and retries twice, with the light flashing 3 times after three ignition failures. It means the Fenwal is not detecting current leakage to ground. The amount of leakage is micro amps and challenging to measure. Here's what seems to be the culprit in order frequency:[4]

- Corrosion—You can verify this by running a separate new wire from the flame detection probe to a ground that's known to be good near the burner. Pentair actually makes a kit for this purpose that can be used on any heater. They all use almost identical flame detection controls. The wire will have to connect in an extremely hot place, so it needs to have silicone high-temperature insulation. This is what's supplied in the Pentair kit.

- Power supply wire insulation integrity. If there is any leakage from the hot wires to the ground coming into your unit, this will interfere with the flame detection signal and cause the Fenwal to flash 3 times. This is almost impossible to test since only a tiny amount of leakage makes the flame detection system inoperable. You may think this isn't likely, but in one case, a lightning strike caused tiny, pin-tip-sized dots along the supply wire insulation. Before you give up, run a jumper wire outside the conduit, disconnect the original wire, and connect the jumper. If this works, replace the original power supply wires with new conductors. Amazingly, this worked, and the problem was solved for one member. He spent weeks troubleshooting and devising bizarre ways to test every component in the system, and every component eventually proved good. Before he gave up and bought a new unit, he figured the power supply was the only thing he didn't prove had any leakage to the ground. It did have the correct voltage.

- Low gas pressure causes a weak flame that isn't strong enough to cause ionized gas particles to produce micro currents to the ground. This is almost always caused by a valve that's been accidentally closed and/or out of propane.

- The Fenwal and gas valves are reliable and rarely fail, especially when you get three red light flashes. This means all the safety devices are working to get you through the heavily protected, complex ignition sequence that gets you to the step where the gas valve opens. The Fenwal is also working to get this far in the sequence. They are also costly. The control board can fail and it's expensive too. If it fails, there are usually some burnt spots you can see. This happened on one after a lightning strike, but the unit still wouldn't work until the power wires were replaced.

JXI High Limit Sensors

A bad Thermal Regulator valve in the water header can cause high limit faults. Check the Thermal Regulator before replacing sensors.

The JXI heaters have two high limit sensors, 135F and 150F, on the bottom rear of one side of the header assembly and the other on the upper front of the other side of the header assembly.[5]

The sensors are simple switches that should be closed when the heater is off. Test the sensor using a multimeter and if it tests open then it needs replacement.

The sensors come as a set of two in a kit. If one fails the manual says to replace both. The 150F is the one with the smaller threads and will only fit that port.

Replacing Leaking Heat Exchanger in Jandy JXI Heater

Jandy JXI400N - Trouble Air describes how a member diagnosed the problems in his Jandy JXI400 heater, discovered the heat exchanger was leaking, and replaced the heat exchanger.

To check if the heat exchanger is leaking remove the ignitor and look into the burner can. If you see any water then you have a leak.

Jandy/Zodiac PC Board Repair

Some members have had good experiences with BP Engineering, Inc. repairing their Jandy boards.

- ↑ https://www.troublefreepool.com/threads/jandy-lt400-temp-control-board-question.204686/post-1814462

- ↑ https://www.troublefreepool.com/threads/jandy-jxi-heater-igniter-issues.238709/

- ↑ https://www.troublefreepool.com/threads/jandy-jxi400-problems.242360/post-2124132

- ↑ https://www.troublefreepool.com/threads/jandy-jxi-wont-ignite.305816/post-2668684

- ↑ https://www.troublefreepool.com/threads/jandy-jxi-400n-heater-high-limit-fault.269417/post-2361128