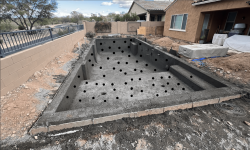

I was told at 28days it will come out to 5500-6000psi?

I have called about 5 civil engineering firms in Phx this morning and one concrete contractor, they think I am from Mars when I ask these questions and none of them do consulting eval.

Am I really asking scary questions? It’s crazy I can get a 2nd opinion for surgery and nobody thinks twice about it. Try to ensure my concrete pool is sound, lol, are you crazy???

any recommendations for a 2nd opinion let me know. PB is acting like I am the most difficult client on the planet, nobody has every asked these questions. I guess I am crazy, lol.

I did get the name of the civil engineering firm that did my design specs, they tried to push me back to the PB until I told them the PB pushed me to them. They said send over pictures, iI am going to ask for the design specs, and the batch tags from the concrete.

I am politely asking these questions and I have not threatened or anyone or been rude in anyway. They just start freaking out when I ask questions that nobody else does and they don’t have answers.

Starting to wonder if I am Pi$$ing into the wind here, lol.

I have called about 5 civil engineering firms in Phx this morning and one concrete contractor, they think I am from Mars when I ask these questions and none of them do consulting eval.

Am I really asking scary questions? It’s crazy I can get a 2nd opinion for surgery and nobody thinks twice about it. Try to ensure my concrete pool is sound, lol, are you crazy???

any recommendations for a 2nd opinion let me know. PB is acting like I am the most difficult client on the planet, nobody has every asked these questions. I guess I am crazy, lol.

I did get the name of the civil engineering firm that did my design specs, they tried to push me back to the PB until I told them the PB pushed me to them. They said send over pictures, iI am going to ask for the design specs, and the batch tags from the concrete.

I am politely asking these questions and I have not threatened or anyone or been rude in anyway. They just start freaking out when I ask questions that nobody else does and they don’t have answers.

Starting to wonder if I am Pi$$ing into the wind here, lol.

Last edited: