I’m trying to get a heat pump installed for my pool.

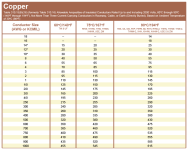

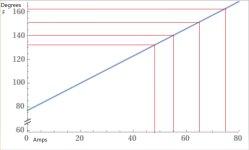

I have an old subpanel fed by 3/4 inch pvc conduit thats about 140 foot long. It’s got #10 wire in it currently. I’d really like to avoid retrenching this conduit, and pull new #6 through here.

I have had a handful of electricians out - a couple have said #6 is too small and redigging the trench has to be done, a couple have said that they won’t pull wire through an old conduit like mine, and a couple said they would pull new wire for a 50 amp breaker.

I have a 1hp pool pump, a salt water chlorine generator, some lights, an automation/wifi panel, and a service outlet for the cleaning robot. I added up the load here to about 12 amps @ 240 volts.

The heat pump I’m looking at has a compressor and fan load of about 30 amps, and an MCA of 42.5.

I used southwire’s minimum gauge calculator and it looks like I can get about 55 amps with <3% voltage drop on #6 conductors at that distance.

When i add the other loads with the MCA of the heat pump, i see that it’s safely under 55 amp.

Not sure what to think - I’d love to save about $3500 on digging the trench and risking hurting a huge old tree, but I also understand its always better to have a bigger subpanel.

Appreciate any feedback if others have been in similar situations - all the electricians seem relatively trustworthy to me.

I have an old subpanel fed by 3/4 inch pvc conduit thats about 140 foot long. It’s got #10 wire in it currently. I’d really like to avoid retrenching this conduit, and pull new #6 through here.

I have had a handful of electricians out - a couple have said #6 is too small and redigging the trench has to be done, a couple have said that they won’t pull wire through an old conduit like mine, and a couple said they would pull new wire for a 50 amp breaker.

I have a 1hp pool pump, a salt water chlorine generator, some lights, an automation/wifi panel, and a service outlet for the cleaning robot. I added up the load here to about 12 amps @ 240 volts.

The heat pump I’m looking at has a compressor and fan load of about 30 amps, and an MCA of 42.5.

I used southwire’s minimum gauge calculator and it looks like I can get about 55 amps with <3% voltage drop on #6 conductors at that distance.

When i add the other loads with the MCA of the heat pump, i see that it’s safely under 55 amp.

Not sure what to think - I’d love to save about $3500 on digging the trench and risking hurting a huge old tree, but I also understand its always better to have a bigger subpanel.

Appreciate any feedback if others have been in similar situations - all the electricians seem relatively trustworthy to me.