- Jul 3, 2013

- 9,027

- Pool Size

- 15000

- Surface

- Vinyl

- Chlorine

- Salt Water Generator

- SWG Type

- CircuPool SJ-40

I would do the grid because I believe it is safer than just 1 wire running under your pavers... The grid is replicating the rebar in a concrete deck that must be connected and bonded... The statement above is correct, it really comes down to the inspector if you have an inspector.. Do you want to "get away" with a cheaper option that "may" put you or your families life in danger if something happened? (not saying it will and hopefully nothing ever happens)

It would be way cheaper in the long run> say if you only ran the 1 wire, finished the paver install and when your getting out of the pool or reaching into the pool and you feel a constant shock and figure out it is not bonded enough and you have to tear out your entire deck, install the bonding grid and reinstall the deck... How much do you think that will cost?

In the end it is your pool, we are just trying to help

I would do exactly the same connection you have on the pool now just put it on the bottom like you were talking about (really in the end your just keeping the bonding grid connected to your pool frame so it does not move)..

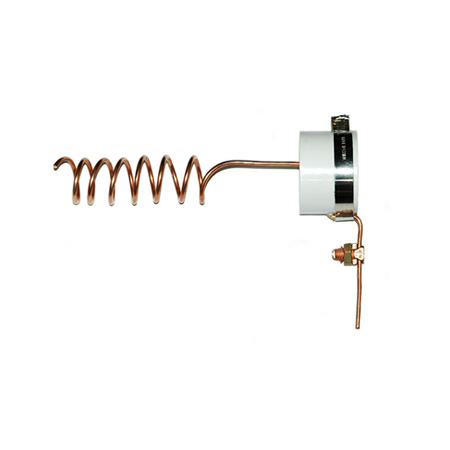

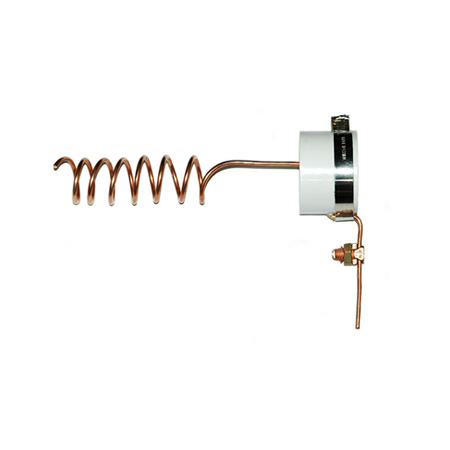

you will also be using a water bonding kit like one of these..

www.cmiwebsite.com

www.cmiwebsite.com

It would be way cheaper in the long run> say if you only ran the 1 wire, finished the paver install and when your getting out of the pool or reaching into the pool and you feel a constant shock and figure out it is not bonded enough and you have to tear out your entire deck, install the bonding grid and reinstall the deck... How much do you think that will cost?

In the end it is your pool, we are just trying to help

I would do exactly the same connection you have on the pool now just put it on the bottom like you were talking about (really in the end your just keeping the bonding grid connected to your pool frame so it does not move)..

you will also be using a water bonding kit like one of these..

2″ Fitting, Stainless Steel wire & #8 Copper Split Bolt <span> Case Qty. 10</span> - Consolidated Manufacturing

Install inline below the water level. WATER BOND FITTING WaterBond150™, WaterBond200™ Bond Water quickly and economically Get your Above-Ground or Fiberglass / Vinyl Liner Pool Electrical Permit Approved! Case Qty. 10

Amazon.com : Burndy Bwb680Ig In Grd Pool Bond Kit : Garden & Outdoor

Amazon.com : Burndy Bwb680Ig In Grd Pool Bond Kit : Garden & Outdoor

smile.amazon.com

Amazon.com: Burndy BWB680AG Waterbug Mechanical connectors, silver: Home Improvement

Amazon.com: Burndy BWB680AG Waterbug Mechanical connectors, silver: Home Improvement

smile.amazon.com