My pool solar valve is acting differently. It now shuts off at what seems like random times of the day when the water temperature isn't any where near the 90 degrees I have it set for. I can tell when it turns back on because I hear the pump speed up to Start speed for about 3 minutes as it should. I check it and the valve is in the On position. I haven't hung around long enough, staring at it, to watch it shut off again but I'll check it after a while and it is in the Off position. It didn't used to do this, it worked great. Now I'm wasting valuable sunshine. I've double checked the Pool Solar temp setting. I don't know what else to look at. Ideas?

Solar valve cycling on and off

- Thread starter AZAA

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Nov 12, 2017

- 11,907

- Pool Size

- 12300

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-40

How long did it work for? More than one season? How old is the system?

There are basically three things responsible for engaging the solar heater: the controller and two temperature sensors. I don't know ProLogic, but I'll assume it's similar to my Pentair ET. It analyzes the two temperature sensor readings, one for the water temp, and the other for roof-top temp, and then decides if both the water is colder than called for and the panels are warm enough to do something about it.

Easiest thing to try first is to find where the two sensors connect to your ProLogic. Turn off all the pool circuit breakers first! Then label the wires and then disconnect them. Cut off the ends, strip them, make sure the newly exposed wire is nice and shiny. If there is any way to inspect and clean/polish the terminals they go to then do that, then reconnect the wires making sure you do so as they were. If that doesn't solve the problem, then...

If you can access through ProLogic the water temperature reading, and it is relatively accurate (say, compared to a floating thermometer in the water), that is one way to find or rule out a bad water temp sensor. If it's way off, replace it. The next easiest thing to check is the roof top sensor. That temp reading should also be accessible somewhere in the ProLogic interface. And sorry, here's where my know-how gets a little iffy. I'm not sure what to tell you that reading should be, but you could at least determine if it was way off or not. On a sunny day it should be a lot hotter than the ambient air temp. Hayward tech support might be able to help with this aspect of the trouble shooting. Or you could just replace the sensor and see if that solves the problem. They're not that expensive, 20 bucks or so. There is a chart that you could use, along with an ohm meter, to test the sensor for accuracy, but again, unless you have a reliable thermometer up on the roof for comparison, measuring the sensor would be of no real value. Replacing it is the simplest, cheapest troubleshooting trick I can muster.

So that's what I'd do. After the other steps I described, I'd find the replacement part and try to order it from Amazon. I'd climb up on the roof, and inspect the sensor. Maybe it'll be something obvious: broken or cracked or buried in a bird's nest. Determine if the wire from the sensor runs uninterrupted to the ProLogic, or if there is a splice somewhere along the way. Redo the splice if you find one: cut, strip (shiny) and reconnect with reliable water-proof connectors (like the type of gooped wire nuts used for irrigation wiring). I would solder the connection if I could. If you find something fixable, fix it and return the Amazon sensor. Otherwise, replace it by splicing in the new one and see if that solves the problem. If you can't find anything wrong with either sensor, or their connections, or any of your ProLogic settings, then I think the next suspect is the ProLogic itself.

The reason I asked about "how long" is to find out if this is your first spring with the system. There's one other thing to try if it is...

There are basically three things responsible for engaging the solar heater: the controller and two temperature sensors. I don't know ProLogic, but I'll assume it's similar to my Pentair ET. It analyzes the two temperature sensor readings, one for the water temp, and the other for roof-top temp, and then decides if both the water is colder than called for and the panels are warm enough to do something about it.

Easiest thing to try first is to find where the two sensors connect to your ProLogic. Turn off all the pool circuit breakers first! Then label the wires and then disconnect them. Cut off the ends, strip them, make sure the newly exposed wire is nice and shiny. If there is any way to inspect and clean/polish the terminals they go to then do that, then reconnect the wires making sure you do so as they were. If that doesn't solve the problem, then...

If you can access through ProLogic the water temperature reading, and it is relatively accurate (say, compared to a floating thermometer in the water), that is one way to find or rule out a bad water temp sensor. If it's way off, replace it. The next easiest thing to check is the roof top sensor. That temp reading should also be accessible somewhere in the ProLogic interface. And sorry, here's where my know-how gets a little iffy. I'm not sure what to tell you that reading should be, but you could at least determine if it was way off or not. On a sunny day it should be a lot hotter than the ambient air temp. Hayward tech support might be able to help with this aspect of the trouble shooting. Or you could just replace the sensor and see if that solves the problem. They're not that expensive, 20 bucks or so. There is a chart that you could use, along with an ohm meter, to test the sensor for accuracy, but again, unless you have a reliable thermometer up on the roof for comparison, measuring the sensor would be of no real value. Replacing it is the simplest, cheapest troubleshooting trick I can muster.

So that's what I'd do. After the other steps I described, I'd find the replacement part and try to order it from Amazon. I'd climb up on the roof, and inspect the sensor. Maybe it'll be something obvious: broken or cracked or buried in a bird's nest. Determine if the wire from the sensor runs uninterrupted to the ProLogic, or if there is a splice somewhere along the way. Redo the splice if you find one: cut, strip (shiny) and reconnect with reliable water-proof connectors (like the type of gooped wire nuts used for irrigation wiring). I would solder the connection if I could. If you find something fixable, fix it and return the Amazon sensor. Otherwise, replace it by splicing in the new one and see if that solves the problem. If you can't find anything wrong with either sensor, or their connections, or any of your ProLogic settings, then I think the next suspect is the ProLogic itself.

The reason I asked about "how long" is to find out if this is your first spring with the system. There's one other thing to try if it is...

Last edited:

Thanks Dirk for your comprehensive answer.

The system is about 5 years old. This is my 3rd season with the pool. The first season I didn't know what the heck I was doing (first pool) so I don't have any reliable info on how things were working, but I think everything was OK.

The second season I was getting a "Solar Switch Open" warning. I figured that was one of the sensors you described, either on the roof or at the pump. I limped along operating the valve manually as I was not anxious to climb up on my tile roof and check the sensor and others wanted $200+ dollars to do it.

THIS year my pump went out and somewhere during the process of installing a new one the guy inadvertently fixed the problem. He didn't know what he had done to fix it, but I wasn't going to question my good luck. From then until a few days ago the valve worked perfectly. It was great! Now the valve still works, just at random times. The temp of the water returning to the pump from the solar can read 90/100 degrees with the pool water at 75. The valve will turn on and off 3 or 4 times a day. I would think if there was a connection problem that it would either stay on or off. But, I will first strip and clean the wires where they plug into the circuit board on the Hayward controller. The next step would be to change the accessible sensor at the pool pump area. If that's not it, I guess I'll call some pool guy who is younger and braver than I to get on the roof and change the other sensor. I guess I was hoping for an easier solution.

Thank you again for responding. TFP is a wonderful source of information. I hope to be able to contribute answers some day and not just keep asking questions.

The system is about 5 years old. This is my 3rd season with the pool. The first season I didn't know what the heck I was doing (first pool) so I don't have any reliable info on how things were working, but I think everything was OK.

The second season I was getting a "Solar Switch Open" warning. I figured that was one of the sensors you described, either on the roof or at the pump. I limped along operating the valve manually as I was not anxious to climb up on my tile roof and check the sensor and others wanted $200+ dollars to do it.

THIS year my pump went out and somewhere during the process of installing a new one the guy inadvertently fixed the problem. He didn't know what he had done to fix it, but I wasn't going to question my good luck. From then until a few days ago the valve worked perfectly. It was great! Now the valve still works, just at random times. The temp of the water returning to the pump from the solar can read 90/100 degrees with the pool water at 75. The valve will turn on and off 3 or 4 times a day. I would think if there was a connection problem that it would either stay on or off. But, I will first strip and clean the wires where they plug into the circuit board on the Hayward controller. The next step would be to change the accessible sensor at the pool pump area. If that's not it, I guess I'll call some pool guy who is younger and braver than I to get on the roof and change the other sensor. I guess I was hoping for an easier solution.

Thank you again for responding. TFP is a wonderful source of information. I hope to be able to contribute answers some day and not just keep asking questions.

- Nov 12, 2017

- 11,907

- Pool Size

- 12300

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-40

Well, if you didn't keep asking questions we wouldn't have anything to do!

I couldn't follow everything you just described, but you might have offered a clue. The water temp coming out of the panels should only be a few degrees warmer than the pool water temp, definitely not 15-25° hotter. It sounds counter intuitive, but that's how you properly tune a solar heater. You want a lot of slightly warmer water heating the pool, not a little of very hot water. It comes down to thermodynamics, of some sort. Anywho, if your solar panel water is that much hotter than the pool, then that means your flow rate through the panels is way too low. And depending on where your roof-top sensor is mounted, that might all be related. The flow-rate issue might also be why a new pump made a difference. And this seemingly random return of the problem might also have something to do with the status of your filter (I know, but stay with me!). If the filter is dirty, and is lowering your flow rate, then that can affect the efficiency of your solar heater, which might have something to do with all this weirdness.

I can only share how I've dealt with some of these issues. Firstly, I installed my own system, and I learned even before I did about the temperature differential I just described, and about the importance of flow rate and how that affects efficiency and performance of the heater. So I included a FlowVis flow meter in my install. I obtained the optimum flow rate number for my panels directly from Helicol (it's in the owner manual). Mine panels want 5GPM, times eight panels, for 40GPM total. It was a simple matter to observe the FlowVis while adjusting my VS pump's RPM to dial in exactly 40GPM. That assures me of the proper temp differential and flow rate for best performance. Then...

When I first started using my system I noticed some odd valve activity, which is why I asked you "how long." It was pretty bad in my first fringe season (Spring), because of the partly cloudy and windy days. So I poked around for some info and someone told me to isolate the roof-top sensor from the wind by placing it under a glass jar. According to this guy, that would eliminate the cooling affect of the wind, and offer up a truer roof-top temp. Which was all contradicted by a local solar installer who said that was crazy talk. I decide to test this out anyway and took the sensor off of the panels and mounted it under a small, glass jar a few inches away from the panel tubing. That stopped the too-often solar switching and it's been up there ever since. Your milage may vary, but know, this trick, apparently, is somewhat controversial.

So... you might have more than one thing going on: a dirty filter, an incorrect flow rate, some bad connections, some sort of wind or dirt or bird weirdness going on up top. Not to mention actual defective components. That's the extend of my "expertise." It might be something a local solar guy could look at and say "Oh, easy, it's your frazzle-hopper valve! You just need a new one!!" Who knows. You can give some of my tips a try, or just call a guy.

By the way, if you do decide to try replacing your sensors as part of your troubleshooting, this might work. My two sensors are the same, interchangeable. If yours are, you could buy one from wherever, and replace the easy one first. If no joy, then use the old one to replace the next one. Two birds kinda thing. And you don't need to get all the way up on the roof to just troubleshoot that one. Disconnect the old one from the controller and connect the new one with a long wire. Then just place it up as high as you can get. Just past the gutter is probably close enough to see if it's the old sensor or not. See what I'm saying? Then if that solves the problem, you can hire a young buck to climb all the way up to put if closer to the panels.

Whatever you try, a few bills is not worth risking your neck, so play it safe...

I couldn't follow everything you just described, but you might have offered a clue. The water temp coming out of the panels should only be a few degrees warmer than the pool water temp, definitely not 15-25° hotter. It sounds counter intuitive, but that's how you properly tune a solar heater. You want a lot of slightly warmer water heating the pool, not a little of very hot water. It comes down to thermodynamics, of some sort. Anywho, if your solar panel water is that much hotter than the pool, then that means your flow rate through the panels is way too low. And depending on where your roof-top sensor is mounted, that might all be related. The flow-rate issue might also be why a new pump made a difference. And this seemingly random return of the problem might also have something to do with the status of your filter (I know, but stay with me!). If the filter is dirty, and is lowering your flow rate, then that can affect the efficiency of your solar heater, which might have something to do with all this weirdness.

I can only share how I've dealt with some of these issues. Firstly, I installed my own system, and I learned even before I did about the temperature differential I just described, and about the importance of flow rate and how that affects efficiency and performance of the heater. So I included a FlowVis flow meter in my install. I obtained the optimum flow rate number for my panels directly from Helicol (it's in the owner manual). Mine panels want 5GPM, times eight panels, for 40GPM total. It was a simple matter to observe the FlowVis while adjusting my VS pump's RPM to dial in exactly 40GPM. That assures me of the proper temp differential and flow rate for best performance. Then...

When I first started using my system I noticed some odd valve activity, which is why I asked you "how long." It was pretty bad in my first fringe season (Spring), because of the partly cloudy and windy days. So I poked around for some info and someone told me to isolate the roof-top sensor from the wind by placing it under a glass jar. According to this guy, that would eliminate the cooling affect of the wind, and offer up a truer roof-top temp. Which was all contradicted by a local solar installer who said that was crazy talk. I decide to test this out anyway and took the sensor off of the panels and mounted it under a small, glass jar a few inches away from the panel tubing. That stopped the too-often solar switching and it's been up there ever since. Your milage may vary, but know, this trick, apparently, is somewhat controversial.

So... you might have more than one thing going on: a dirty filter, an incorrect flow rate, some bad connections, some sort of wind or dirt or bird weirdness going on up top. Not to mention actual defective components. That's the extend of my "expertise." It might be something a local solar guy could look at and say "Oh, easy, it's your frazzle-hopper valve! You just need a new one!!" Who knows. You can give some of my tips a try, or just call a guy.

By the way, if you do decide to try replacing your sensors as part of your troubleshooting, this might work. My two sensors are the same, interchangeable. If yours are, you could buy one from wherever, and replace the easy one first. If no joy, then use the old one to replace the next one. Two birds kinda thing. And you don't need to get all the way up on the roof to just troubleshoot that one. Disconnect the old one from the controller and connect the new one with a long wire. Then just place it up as high as you can get. Just past the gutter is probably close enough to see if it's the old sensor or not. See what I'm saying? Then if that solves the problem, you can hire a young buck to climb all the way up to put if closer to the panels.

Whatever you try, a few bills is not worth risking your neck, so play it safe...

- Nov 12, 2017

- 11,907

- Pool Size

- 12300

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-40

Speaking of which, today is the day I rewire some of my pool gear. If I don't electrocute myself doing it, I'll post the whole story. So bye for now... good luck with your heater!

Well...hope you're still with me Sparky  .

.

I think you hit on something with the flow rate thing. A few days ago (about the time this all started), a representative from Heliocol came out to give me a quote on an auxiliary electric heater. I asked in a by-the-way sort of fashion what pump speed should I be using to get the most out of my solar. He said about 20/2200RPM. Since the pump was set at a higher RPM I dialed it down a bit. So although the problem started then, my return temp as you noted is still 15 to 25 degrees warmer than the pool. Perhaps a higher speed will reduce the differential in temp(?).

I cleaned my 4-cartridge filter a couple of months ago, so I don't think that's it.

Without a FloVis gadget, is there a way to measure GPM? I guess I'll just mess around with my VS pump to see if the problem stops.

Thanks again.

I think you hit on something with the flow rate thing. A few days ago (about the time this all started), a representative from Heliocol came out to give me a quote on an auxiliary electric heater. I asked in a by-the-way sort of fashion what pump speed should I be using to get the most out of my solar. He said about 20/2200RPM. Since the pump was set at a higher RPM I dialed it down a bit. So although the problem started then, my return temp as you noted is still 15 to 25 degrees warmer than the pool. Perhaps a higher speed will reduce the differential in temp(?).

I cleaned my 4-cartridge filter a couple of months ago, so I don't think that's it.

Without a FloVis gadget, is there a way to measure GPM? I guess I'll just mess around with my VS pump to see if the problem stops.

Thanks again.

- Nov 12, 2017

- 11,907

- Pool Size

- 12300

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-40

There are guys that can guesstimate your flow rate based on math: something to do with the pipes and pump and elbows and heights, etc. Others can tune a solar panel array just by feeling the water coming out of the returns. There might be some other ways. I didn't mess with any of those. I needed a check valve for my solar plumbing and the FlowVis doubles as one, so for 50 bucks more I got the Vis, problem solved, and way more accurate than any other method. If you already have a Jandy check valve somewhere in your plumbing, FlowVis sells just the guts that will retrofit into the Jandy check valve. The flow meter doesn't have to be in the solar loop. Flow is constant so wherever your check valve is it'll work. Mine is just before my filter. I have another in the solar loop, too, both Jandy bodies so I can move the Vis from one location to the other. But in front of the filter it works for solar, and helps me track filter status, flow rate through the SWG and suction through my cleaner vac. It was worth the cost to me, I still use it all the time. If the filter gets dirty before cleaning time, the Vis reveals that and I can up the pump RPM a notch or two to compensate, then back down after I clean the filter. It really allows fine tuning. Not all that necessary in the grand scheme, but I like to be "just so" with all things pool.

The slower the flow, the hotter the water. Higher flow would reduce the temp. It's about how much time the water is in the panels. The panels will have an optimum and maximum flow rate. Above the optimum just wastes electricity. Above the max risks the panel structure. My optimum flow rate of 40GPM takes 2200 RPM from my VS pump. I have eight 12' Heliocols. So it sounds like your Heliocol rep corroborates. Of course the actual flow rate is dependent on many variables, but 2200 is as good a place as any to start.

If you're running your pump higher than expected, perhaps there is a restriction somewhere in the panels that is keeping the water up there too long. Do you run only filtered water through them?

Do you have a vacuum breaker? And a solar drain-down valve? Does the water drain out of the panels when the pump shuts off for the day? Do you get a lot of air in the morning when the solar first engages? If you temp 15° higher only at first? Or all day long?

The slower the flow, the hotter the water. Higher flow would reduce the temp. It's about how much time the water is in the panels. The panels will have an optimum and maximum flow rate. Above the optimum just wastes electricity. Above the max risks the panel structure. My optimum flow rate of 40GPM takes 2200 RPM from my VS pump. I have eight 12' Heliocols. So it sounds like your Heliocol rep corroborates. Of course the actual flow rate is dependent on many variables, but 2200 is as good a place as any to start.

If you're running your pump higher than expected, perhaps there is a restriction somewhere in the panels that is keeping the water up there too long. Do you run only filtered water through them?

Do you have a vacuum breaker? And a solar drain-down valve? Does the water drain out of the panels when the pump shuts off for the day? Do you get a lot of air in the morning when the solar first engages? If you temp 15° higher only at first? Or all day long?

I don't know what a vacuum breaker is but I'll do some research.Do you have a vacuum breaker? And a solar drain-down valve? Does the water drain out of the panels when the pump shuts off for the day? Do you get a lot of air in the morning when the solar first engages? If you temp 15° higher only at first? Or all day long?

I'll also research what a Jandy valve is. Like I said, this stuff is all new to me.

I think a Solar drain down-valve would be the ball valve in the down (hot) pipe. Right?

Yes, a lot of bubbles when the system turns on in the morning as well as each time the pump ramps up when the system turns on during the day. I've assumed it is because the solar panels (7) have drained and are full of air.

I don't know about the temp first thing in the morning. I would expect there would be little difference between "up" and "down" when it first fires up.

OK, yes, I have an electrically operated valve for my Solar on/off as well as a manually operated drain/skimmer valve.

EDIT: After further research I find I have NO Jandy valves, only the two listed above. I watched some videos regarding installing a complete FloVis. I can do that.

EDIT: And there appears to be a vacuum breaker where the water supply comes out of the house and is diverted to the hose spigot and pool.

EDIT: After further research I find I have NO Jandy valves, only the two listed above. I watched some videos regarding installing a complete FloVis. I can do that.

EDIT: And there appears to be a vacuum breaker where the water supply comes out of the house and is diverted to the hose spigot and pool.

Last edited:

- Nov 12, 2017

- 11,907

- Pool Size

- 12300

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-40

OK, so you're close...

As I mentioned, perhaps post some pictures of your pad and solar pipes and let's see whatcha got.

A vacuum breaker would be on or near your roof. It allows air into the panels when the system is off and the panels are trying to drain, otherwise the vacuum could deform the tender tubes, even the hot PVC. Mine sounds like a frog when the panels are draining.I don't know what a vacuum breaker is but I'll do some research.

Sounds like you have that sorted out.I'll also research what a Jandy valve is. Like I said, this stuff is all new to me.

If you post a pic or two of your setup I'll help you identify what's what. The ball valve you describe is probably your solar isolation valve. Typically there are two of those, one on each pipe leading to the roof: supply and return. Then there is the three-way solar valve. If your system is automated (sounds like it is), then that three-way will have an actuator attached to it (what you call "electrically operated valve"). That's your solar valve. There are special versions of three-way valves that allow the panels to "drain-down" through them when the pump is off. The return pipe from the panels will drain down directly to the pool. But with the solar valve in "solar off" mode, a normal three-way will trap the water on the supple side in the pipes and the panels. Most of the water comes down through the supply side, so a solar drain down valve is used to allow all that water to escape. You'd have to try and find a model number on the valve (not the actuator) to find out if that's what you have or not. Sometimes you can hear the water coming down through it when the pump is off. But it's also coming down through the return pipe, so it can be hard to determine.I think a Solar drain down-valve would be the ball valve in the down (hot) pipe. Right?

OK, so that's sort'a good. The panels are supposed to drain at the end of the pump run. The bubbles in the morning are a good sign that that are. That's the pump filling the panels with water and pushing the air out to the pool. But that should happen only once a day (or rather, once a pump on-off cycle). If your pump is cycling from low to high RPMs, when the solar controller calls for heat, then back to low when the controller determines the pool is warm enough (or the sun isn't going to heat the pool), then the water should NOT drain at that point. Only if the pump actually shuts off (0 RPM, no flow). If the panels are draining while the pump is still running low, and/or you're getting bubbles every time the pump switches from low RPM to high, then something is wrong.Yes, a lot of bubbles when the system turns on in the morning as well as each time the pump ramps up when the system turns on during the day. I've assumed it is because the solar panels (7) have drained and are full of air.

That was a question to see if the water is being held in the panels overnight. Which it shouldn't be. It sounds like your panels are draining, but we've yet to determine if they're draining completely.I don't know about the temp first thing in the morning. I would expect there would be little difference between "up" and "down" when it first fires up.

Yep, that's your solar three-way valve. We just need to figure out if it's the drain-down type.OK, yes, I have an electrically operated valve for my Solar on/off

That's unrelated to your solar heater system. That's your suction-side manifold, that balances how much water comes through your drain and skimmer, one or the other of some from both.as well as a manually operated drain/skimmer valve.

Coolio. We can help you find the best spot for that. Did they talk about that in the videos?EDIT: After further research I find I have NO Jandy valves, only the two listed above. I watched some videos regarding installing a complete FloVis. I can do that.

That's something else, also unrelated to your solar heater. It's probably a backflow preventer of some sort (BFP). One of its components is a "vacuum breaker." But a different type. The solar heater version is more accurately called a "Vacuum Relief Valve" or VRV. That's my bad, sorry for the confusion. A BFP stops the pool water from getting sucked into the neighborhood water main during a backflow event (like a broken water main), and a VRV lets air into your solar panels when they need it.EDIT: And there appears to be a vacuum breaker where the water supply comes out of the house and is diverted to the hose spigot and pool.

As I mentioned, perhaps post some pictures of your pad and solar pipes and let's see whatcha got.

Last edited:

1. I don't know if I have a VRV at this point.

2. I'm not finding anything that fits your description of a solar drain down valve. The pic shows an in-line "valve"(?) on the return pipe similar in shape to a Jandy valve but without the screws (and the Jandy name). It doesn't seem to have any valuable info on it. Note the 3-way valve is in the off position at this time (I just heard the solar turn on so I'll monitor today to see if the bump in "valve 3 speed" solves the issue)

3. The videos were really good but I don't have a section long enough to install the Vis at this time. I would need to install a loop in the line and I'm not quite ready to tackle that.

4. Yes, the bubbles appear each time the solar valve turns on, even in the middle of the day (this mid day cycling is the thing I'm concerned with).

I've tried to attach pictures. Let's see if this works...

2. I'm not finding anything that fits your description of a solar drain down valve. The pic shows an in-line "valve"(?) on the return pipe similar in shape to a Jandy valve but without the screws (and the Jandy name). It doesn't seem to have any valuable info on it. Note the 3-way valve is in the off position at this time (I just heard the solar turn on so I'll monitor today to see if the bump in "valve 3 speed" solves the issue)

3. The videos were really good but I don't have a section long enough to install the Vis at this time. I would need to install a loop in the line and I'm not quite ready to tackle that.

4. Yes, the bubbles appear each time the solar valve turns on, even in the middle of the day (this mid day cycling is the thing I'm concerned with).

I've tried to attach pictures. Let's see if this works...

- Nov 12, 2017

- 11,907

- Pool Size

- 12300

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-40

Excellent! OK...

Google "solar heater vacuum relief valve" and click "Images" and you'll see lots of different types.

The Hayward GVA-24 is the actuator. That's not actually the solar three-way valve, but it's bolted to it. The solar-valve is under the actuator, and is operated by it. If you had a solar drain-down valve, it would be that three-way valve. You're not looking for something other than that one. It's that valve, under the actuator, that you need to find some numbers on, to determine if that is a standard three-way, or a solar drain down type. Unfortunately, that's not the end of it, because some installers know how to modify a standard three-way into a drain-down, just by drilling a hole somewhere inside it. I know...

Pics came through fine. Starting at the top,

#1: that's a check valve.

#2: two check valves and the solar actuator with the solar three-way valve underneath the actuator. The check on the left is on your solar return line. The check on the right, just after the pool filter, is where your FlowVis might go. Take a zoomed out shot of that area so I can see the pipe(s) coming off the filter. You might get the FlowVis in there, without the loop you're describing. The gizmo under the check valve on the right looks to be a saltwater chlorine generator cell.

#3: your feet are pointing at your suction-side manifold. I'm a bit confused about the rest. Typically that manifold leads to a pump, which is kinda what that looks like, only half a pump. I'm not sure what I'm looking at. Is that two pumps side by side? Might need a better shot of that, different angle.

#4: OK, now I see where you're getting your temp readings from! The two grey-handled ball valves are your solar isolation valves. I don't like those, but they are not uncommon. They would be used to isolate your solar panels from the rest of your pool plumbing. Perhaps for winterizing? But do you winterize? Here's the rub. The check valve on your return line already isolates that side. And the solar valve, when in "solar off" mode, isolates the supply side. So the ball valves are not only redundant, but hazardous. If either of the ball valves are closed, and you inadvertently turn on your solar and the solar valve engages the panels, depending on which isolation valve is closed, you'll either blow up your pump or your filter or the panels or all of them! My system has no such valves, and glad for it. Don't ever mess with them, would be my advice. The red-handled hose bib is for draining the supply side pipe and the panels. Typically there is one on each side, but the return side would drain to the pool, so maybe that's why they left if out. Remember, I mentioned before how the solar valve can trap water on the supply side, the hose bib is for draining the supply side. But if you never winterize your pool, then you don't ever need to mess with that valve either, especially if you find you have a solar drain-down three-way valve.

So... the thermometers. So ideally the return temp should only be a few degrees warmer than the supply temp. This, I assume, is how you're reporting the 15° differential? The two temp gauges can be used to tune your system, instead of the FlowVis, but that's assuming they both work, and are both accurate. 15° is a lot. Not right, as I've mentioned, but so much that it makes me suspect the gauges. Not sure what's to be done about that. If you're feeling adventurous, you could swap them. Wait until mid day, after the solar has been running a while. Note the reading. Have some teflon tape handy. Shut down the pad and swap the gauges (quickly), then restart the system. If you get the same differential, then your gauges are OK (or at least equally inaccurate). If the readings are wildly different than before the swap, then you've got one or both bad gauges.

I still claim adjusting flow is the better way to tune solar panels, but perhaps others would disagree. If you run your pump between 2000-2500 RPM and the temperature differential between the two gauges is more than a few degrees, something's wrong.

OK, off to the salt mines. More later if you need...

Sometimes they're "hidden" in the end cap of the solar panel header manifold up on the roof. Others look like this, up on the roof or just under the eves:1. I don't know if I have a VRV at this point.

Google "solar heater vacuum relief valve" and click "Images" and you'll see lots of different types.

The two black gizmos with the "flow" arrows on them are your check valves. They appear to be located where I would expect them to be, so that's good. You're right, neither are Jandy and so won't accept the FlowVis Retrofit kit. Ideally, you'd replace the one just after the filter, not the other one. Just after the filter will give you flow readings whether your solar was engaged or not. With a pic a bit zoomed back I might be able to offer a way to get the FlowVis in there. They double as check valves, so you can safely replace a check valve with a FlowVis.2. I'm not finding anything that fits your description of a solar drain down valve. The pic shows an in-line "valve"(?) on the return pipe similar in shape to a Jandy valve but without the screws (and the Jandy name). It doesn't seem to have any valuable info on it. Note the 3-way valve is in the off position at this time (I just heard the solar turn on so I'll monitor today to see if the bump in "valve 3 speed" solves the issue)

The Hayward GVA-24 is the actuator. That's not actually the solar three-way valve, but it's bolted to it. The solar-valve is under the actuator, and is operated by it. If you had a solar drain-down valve, it would be that three-way valve. You're not looking for something other than that one. It's that valve, under the actuator, that you need to find some numbers on, to determine if that is a standard three-way, or a solar drain down type. Unfortunately, that's not the end of it, because some installers know how to modify a standard three-way into a drain-down, just by drilling a hole somewhere inside it. I know...

See above.3. The videos were really good but I don't have a section long enough to install the Vis at this time. I would need to install a loop in the line and I'm not quite ready to tackle that.

Let's make sure we're talking about the same thing. When the "solar valve turns on" does the pump go from low speed to high, or does the pump actually start up from off? In other words, is the pump running all day, at low speed, and just ramp up for solar? Or is the pump off all the time, and only comes on when the solar valve turns?4. Yes, the bubbles appear each time the solar valve turns on, even in the middle of the day (this mid day cycling is the thing I'm concerned with).

I've tried to attach pictures. Let's see if this works...

Pics came through fine. Starting at the top,

#1: that's a check valve.

#2: two check valves and the solar actuator with the solar three-way valve underneath the actuator. The check on the left is on your solar return line. The check on the right, just after the pool filter, is where your FlowVis might go. Take a zoomed out shot of that area so I can see the pipe(s) coming off the filter. You might get the FlowVis in there, without the loop you're describing. The gizmo under the check valve on the right looks to be a saltwater chlorine generator cell.

#3: your feet are pointing at your suction-side manifold. I'm a bit confused about the rest. Typically that manifold leads to a pump, which is kinda what that looks like, only half a pump. I'm not sure what I'm looking at. Is that two pumps side by side? Might need a better shot of that, different angle.

#4: OK, now I see where you're getting your temp readings from! The two grey-handled ball valves are your solar isolation valves. I don't like those, but they are not uncommon. They would be used to isolate your solar panels from the rest of your pool plumbing. Perhaps for winterizing? But do you winterize? Here's the rub. The check valve on your return line already isolates that side. And the solar valve, when in "solar off" mode, isolates the supply side. So the ball valves are not only redundant, but hazardous. If either of the ball valves are closed, and you inadvertently turn on your solar and the solar valve engages the panels, depending on which isolation valve is closed, you'll either blow up your pump or your filter or the panels or all of them! My system has no such valves, and glad for it. Don't ever mess with them, would be my advice. The red-handled hose bib is for draining the supply side pipe and the panels. Typically there is one on each side, but the return side would drain to the pool, so maybe that's why they left if out. Remember, I mentioned before how the solar valve can trap water on the supply side, the hose bib is for draining the supply side. But if you never winterize your pool, then you don't ever need to mess with that valve either, especially if you find you have a solar drain-down three-way valve.

So... the thermometers. So ideally the return temp should only be a few degrees warmer than the supply temp. This, I assume, is how you're reporting the 15° differential? The two temp gauges can be used to tune your system, instead of the FlowVis, but that's assuming they both work, and are both accurate. 15° is a lot. Not right, as I've mentioned, but so much that it makes me suspect the gauges. Not sure what's to be done about that. If you're feeling adventurous, you could swap them. Wait until mid day, after the solar has been running a while. Note the reading. Have some teflon tape handy. Shut down the pad and swap the gauges (quickly), then restart the system. If you get the same differential, then your gauges are OK (or at least equally inaccurate). If the readings are wildly different than before the swap, then you've got one or both bad gauges.

I still claim adjusting flow is the better way to tune solar panels, but perhaps others would disagree. If you run your pump between 2000-2500 RPM and the temperature differential between the two gauges is more than a few degrees, something's wrong.

OK, off to the salt mines. More later if you need...

Last edited:

OK, wow! I think the Cliff Notes to Gone With the Wind are shorter than that!  Lets go...

Lets go...

I haven't looked for the vacuum relief valve. That's a roof trip that I'm not quite ready to take. After reading the rest you can let me know if that's still an important component to my issue.

I'll assume the valve under the GVA-24 is of no help. I think getting the FlowVis into the spot where the second check valve is would be a problem. I'll include another pic of that area.

The pump runs for 8 1/2 hours now. The high speed start-up then back to a 2200ish speed until the solar kicks in. After another start-up speed it settles into my "Valve 3" set speed (2000 after talking to the HelioCol guy, 2588 before that). Before all of this problem started, the solar valve would remain open the rest of the day assuming it didn't reach the pre-selected temperature max, which it hasn't yet this Spring. After reaching the shutdown time of 5:00 PM all is quiet. So no, the motor does not shut off and start up during the day. Since this problem started the motor would ramp up to start speed, bubbles and all, each time the solar valve would re-open during the day.

The thermometers may be an issue, but I'll check that later. I don't think they affect the present problem. Right now, outside temp is 60. "Up" water from the pool is 80. Return water is 95.

Now, here's the punch line. After increasing the Valve-3 pump speed to 2588 this morning, the solar valve hasn't turned off once! It seems the slower speed recommended by HelioCol was the issue, but that doesn't jibe with your experience. And how would I adjust the temperature differential (even if the thermometers are toast) if I cannot dial down the speed without causing the pump to cycle? It appears right now that if I leave things as they are (and were), all is kosher. The pool heated up to my satisfaction regardless of the temp differential. If as you have said "You want a lot of slightly warmer water heating the pool, not a little of very hot water" wouldn't a lot of warmer water require even a higher pump speed?

the slower speed recommended by HelioCol was the issue, but that doesn't jibe with your experience. And how would I adjust the temperature differential (even if the thermometers are toast) if I cannot dial down the speed without causing the pump to cycle? It appears right now that if I leave things as they are (and were), all is kosher. The pool heated up to my satisfaction regardless of the temp differential. If as you have said "You want a lot of slightly warmer water heating the pool, not a little of very hot water" wouldn't a lot of warmer water require even a higher pump speed?

I still think a FlowVis would be a handy addition to my system if only to adjust run time and pump speed when the solar is not functioning.

Are these pics more helpful?

I haven't looked for the vacuum relief valve. That's a roof trip that I'm not quite ready to take. After reading the rest you can let me know if that's still an important component to my issue.

I'll assume the valve under the GVA-24 is of no help. I think getting the FlowVis into the spot where the second check valve is would be a problem. I'll include another pic of that area.

The pump runs for 8 1/2 hours now. The high speed start-up then back to a 2200ish speed until the solar kicks in. After another start-up speed it settles into my "Valve 3" set speed (2000 after talking to the HelioCol guy, 2588 before that). Before all of this problem started, the solar valve would remain open the rest of the day assuming it didn't reach the pre-selected temperature max, which it hasn't yet this Spring. After reaching the shutdown time of 5:00 PM all is quiet. So no, the motor does not shut off and start up during the day. Since this problem started the motor would ramp up to start speed, bubbles and all, each time the solar valve would re-open during the day.

The thermometers may be an issue, but I'll check that later. I don't think they affect the present problem. Right now, outside temp is 60. "Up" water from the pool is 80. Return water is 95.

Now, here's the punch line. After increasing the Valve-3 pump speed to 2588 this morning, the solar valve hasn't turned off once! It seems

I still think a FlowVis would be a handy addition to my system if only to adjust run time and pump speed when the solar is not functioning.

Are these pics more helpful?

Sorry, I don't know what happened with that double picture post thing  .

.

Hey, it's Sunday. Have some fun. Leave this alone for a while. It's been great having you share your knowledge with me. Hope to hear your response to all of this tomorrow.

Hey, it's Sunday. Have some fun. Leave this alone for a while. It's been great having you share your knowledge with me. Hope to hear your response to all of this tomorrow.

- Nov 12, 2017

- 11,907

- Pool Size

- 12300

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-40

On a short break. I'll come back later to address. The new pic of the pump is the one I could identify before. The skimmer/drain valve leads into something with a lid. That's what I was questioning. It looks a bit like a pump basket, but couldn't be. Is that some sort of pre-filter?

The reason I was pushing you to find and identify everything was to determine if you either have all the foundation of a sound system, or if something is missing. The subsequent bubbles are still a mystery. You should get one good set when the solar system first engages, and then that's it until the next day (the next time you restart the pump). One possibility: if the vacuum relief valve is failing, which happens, it might be letting in air during the solar down cycle (like when a cloud passes over). The panels drain some, though the return pipe, and then the air flushes out the next time solar engages. Do you notice the first round of bubbles being significantly more than the other bubble events?

There may be a way to get a FlowVis in there. I'll explain how later. Happy Sunday!

The reason I was pushing you to find and identify everything was to determine if you either have all the foundation of a sound system, or if something is missing. The subsequent bubbles are still a mystery. You should get one good set when the solar system first engages, and then that's it until the next day (the next time you restart the pump). One possibility: if the vacuum relief valve is failing, which happens, it might be letting in air during the solar down cycle (like when a cloud passes over). The panels drain some, though the return pipe, and then the air flushes out the next time solar engages. Do you notice the first round of bubbles being significantly more than the other bubble events?

There may be a way to get a FlowVis in there. I'll explain how later. Happy Sunday!

- Nov 12, 2017

- 11,907

- Pool Size

- 12300

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-40

It's a matter of diminishing returns. The more water you move, the better you'll heat the pool. But as you increase more and more, the amount of extra heat tapers off. So at some point you're using more electricity than it's worth. Pump energy use is exponential. 10% more RPM costs considerably more than 10% more. So when panels are optimized, it's not actually the most heat they can produce, but rather the most heat you're going to get for a reasonable electric bill. I think there's some wear and tear in there too. Heliocol's have those little tubes, and they're tough, but I would think the more pressure they're under the more likely they'll fail.

Anywho...

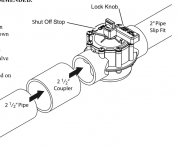

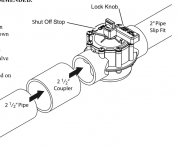

Many brands of plumbing components have a nice feature. You can connect one size pipe to their ports by gluing the pipe inside, and the next larger size gluing a coupler to the outside of the port, and attaching the larger pipe to that. So typically you can connect either 2" or 2.5" pipe.

And that would be true of the ports in a FlowVis body, which is Jandy. It might also be true for your solar valve port, and possibly those check valves. If you buy a short length of 2.5" pipe (some big box stores carry 2' chunks), you can bring that home and measure the circumference with a tape, or even a strip of paper. Compare that circumference to the port on your three-way valve and the port on the check valve. If they are are all the same, then this will work:

I think the total length and angles of all the new components will all end up equaling what is there now. It'll be close. You might fit everything new together before you cut, to make sure of that.

If you want to do a quick feasibility check: a 2.5" PVC pipe has an outside diameter of 2.875". That should mean it's circumference is 9.0321". If you throw a tape measure around the port of your three-way and the port of your check valve, and they're both 9", then you're good to go.

Alternately, you could try to find a spec sheet or owner manual for that check valve and see if it specifically states that you can glue a 2.5" coupler to the outside of the port.

Anywho...

Many brands of plumbing components have a nice feature. You can connect one size pipe to their ports by gluing the pipe inside, and the next larger size gluing a coupler to the outside of the port, and attaching the larger pipe to that. So typically you can connect either 2" or 2.5" pipe.

And that would be true of the ports in a FlowVis body, which is Jandy. It might also be true for your solar valve port, and possibly those check valves. If you buy a short length of 2.5" pipe (some big box stores carry 2' chunks), you can bring that home and measure the circumference with a tape, or even a strip of paper. Compare that circumference to the port on your three-way valve and the port on the check valve. If they are are all the same, then this will work:

I think the total length and angles of all the new components will all end up equaling what is there now. It'll be close. You might fit everything new together before you cut, to make sure of that.

If you want to do a quick feasibility check: a 2.5" PVC pipe has an outside diameter of 2.875". That should mean it's circumference is 9.0321". If you throw a tape measure around the port of your three-way and the port of your check valve, and they're both 9", then you're good to go.

Alternately, you could try to find a spec sheet or owner manual for that check valve and see if it specifically states that you can glue a 2.5" coupler to the outside of the port.

Last edited:

- Nov 12, 2017

- 11,907

- Pool Size

- 12300

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-40

This particular Waterway Check Valve does in fact allow the two sizes of pipe connections I was describing. If your Waterway check valve is the same, then it'll work.

WATERWAY 2" SWING CHECK

WATERWAY 2" SWING CHECK: WATERWAY SWING CHECK VALVE:. . STRAIGHT BODY. 2" SOCKET X 2.5 " SPIGOT. UNION LOCK RING ALLOWS FOR EASY ACCESS. SEAL

waterwayparts.com

Sorry to ignore your previous helpful post for so long...sometimes life gets in the way.

After having bumped up my Valve 3 (solar) speed the on/off cycling of the pump seems to have stopped. We just had the couple of sunny days I needed to verify. I had bumped it up two speeds but I will experiment with the one speed lower to see if I can reduce the differential between incoming and outgoing water without experiencing the cycling again.

That's a very informative photo you have included above. Having done some PVC work with my irrigation systems in Oregon I doubt it's possible to add the 90 degree elbow without enough room to include a threaded connector. In any event, the FlowVis is probably on the back burner for a while.

You have helped me in the past Dirk and I have read your helpful advice in other posted questions. You're one of the reasons TFP is such a wonderful resource. I thank you once again for all the time you have taken to answer my question. I am happy with the outcome. Stay tuned for my next disaster .

.

After having bumped up my Valve 3 (solar) speed the on/off cycling of the pump seems to have stopped. We just had the couple of sunny days I needed to verify. I had bumped it up two speeds but I will experiment with the one speed lower to see if I can reduce the differential between incoming and outgoing water without experiencing the cycling again.

That's a very informative photo you have included above. Having done some PVC work with my irrigation systems in Oregon I doubt it's possible to add the 90 degree elbow without enough room to include a threaded connector. In any event, the FlowVis is probably on the back burner for a while.

You have helped me in the past Dirk and I have read your helpful advice in other posted questions. You're one of the reasons TFP is such a wonderful resource. I thank you once again for all the time you have taken to answer my question. I am happy with the outcome. Stay tuned for my next disaster

- Nov 12, 2017

- 11,907

- Pool Size

- 12300

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-40

Thanks for the kind words. So glad you found a solution! And thanks for supporting TFP, that's what really makes this place work.

Last edited:

Thread Status

Hello , This thread has been inactive for over 60 days. New postings here are unlikely to be seen or responded to by other members. For better visibility, consider Starting A New Thread.