- Mar 29, 2012

- 160

Five years ago I hacked apart my dead Hayward T-15 for "science". This week my Chlorinator Pro CP-15 gave up the ghost. Once again, I disassembled it and here are the pictures...

Notes:

- The electrodes were not corroded. They broke during violent disassembly.

- The sealant was not tar like. It felt and smelled like epoxy.

- Plate erosion was minimal.

- The coatings were mostly deep black and paper thin.

- Cell took 2-3 hits with a 3# hammer before breaking. NUMEROUS hard strikes to separate and open.

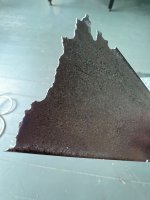

Plate Erosion

#3 - Free floating plate

Broken plate-electrode weld

Floating plate wire brushed

Three electrodes broken away from plates

Drilling into sealing epoxy

First 5 plates

Middle three plates

Right 5 plates

Temperature sensor?

Plate Carrier

Plate and broken electrode, in carrier

Notes:

- The electrodes were not corroded. They broke during violent disassembly.

- The sealant was not tar like. It felt and smelled like epoxy.

- Plate erosion was minimal.

- The coatings were mostly deep black and paper thin.

- Cell took 2-3 hits with a 3# hammer before breaking. NUMEROUS hard strikes to separate and open.

Plate Erosion

#3 - Free floating plate

Broken plate-electrode weld

Floating plate wire brushed

Three electrodes broken away from plates

Drilling into sealing epoxy

First 5 plates

Middle three plates

Right 5 plates

Temperature sensor?

Plate Carrier

Plate and broken electrode, in carrier

Last edited: