I don't know anything about the "expert" part

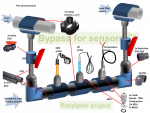

, but with all the info I could garner from members here as well as other info I could find on the internet, this is how I chose to plumb my sensor bypass.

I used a Jandy 3-Way, three 2"s x 2"s x 3/4"t tees and one 2"s x 2"s x 3/4"s tee for the EC probe since the compression fitting that the Atlas Scientific Industrial probe tee inlet and outlet is 3/4" threaded and I wanted 2" slip. So I bought another compression fitting and made my own.

I used a FlowVis to get an approximate idea of water flow through the bypass. Not so much for the gauge but for the clear plastic window as you can see the water flowing and approximate the flow or at least tell that there is minimal water flow through the bypass. This is so the water does not rush past the sensors too fast when pump speed is in vac mode, etc. I do realize that a FlowVis creates some back pressure but all things considered, I did not feel this was too much of a problem.

I chose to install a spare 3/4" threaded tee (which is capped), just in case and for some "future proofing"... Coz cutting into existing plumbing is a real pain.

I am reading H2O temp through the EC probe and additionally installed a FAT and humidity sensor in the bottom of my new Automation Enclosure. Also installed an Atlas Scientific Pressure Sender which is giving me Filter Pressure readings.

Eventually I plan on adding an MA tank level sensor and I am currently waiting on an additional card that I will install in my Precision Digital ProVu Water Refill meter that will provide a 4-20mA signal and eventually hope to incorporate that and all of the rest of these sensor readings into the new

relayEquipmentManager, which will be integrated with the

nodejs-poolController-dashPanel, which I am currently running as my "go to" HMI now for pool automation and control.

Also, I am planning on using one of the Sequent MicroSystems relays mounted on the Raspi Stack to control MA dosing and eventually take MA dosing control completely away from my current IntellipH MA dosing device.

Still lots of work to be done, but I'm getting there (thanks to lots of advice from several members here). This is just about where I'm currently at, when it comes to sensor readings prior to some further pH and EC calibrations.

r.