Problem Summary:

Since I purchased the pool ~5 years ago the Pentair mastertemp 400 would heat in short cycles taking a very long time to heat (6+ hours) here in central Florida even on hot days. Now occasionally it will light “Service Heater” but that can be cleared by a restart and it will on subsequent tries go back to what I believe is anomalous short cycling. My goal is to remedy both things.

Problem Details:

Since I had this Pentair equipment installed approximately 5 years ago the Pentair Mastertemp 400 (NG fed unit) would cycle even before it reaches setpoint and it takes 4+ hours to heat. I thought this was normal.

Recently, I got a service heater light and it would lock out.

Since I purchased the pool ~5 years ago the Pentair mastertemp 400 would heat in short cycles taking a very long time to heat (6+ hours) here in central Florida even on hot days. Now occasionally it will light “Service Heater” but that can be cleared by a restart and it will on subsequent tries go back to what I believe is anomalous short cycling. My goal is to remedy both things.

Problem Details:

Since I had this Pentair equipment installed approximately 5 years ago the Pentair Mastertemp 400 (NG fed unit) would cycle even before it reaches setpoint and it takes 4+ hours to heat. I thought this was normal.

Recently, I got a service heater light and it would lock out.

- With Service Heater on front panel the PCB has the green spa on and now RED LED10 but no other red LED. No lights on FENWAL

- In troubleshooting I found if I power cycled the unit it would often go back to what I believe is its original but still anomalous behavior with these short cycles. When it does this it never throws an error LED or code on the PCB or the fenwall LED…no red LEDs anywhere. It just short cycles until it achieves setpoint.

- After getting the service light I began to troubleshoot and If I understand the videos and the “Master Temp Further Reading” post on TFP, the short cycling is anomalous as is of course the occasional service heater LED. I am wanting to correct both.

- I started by replacing sensors ( HLS, SFS, and heater Thermistor without checking if they were bad. This did not solve and there was no difference in behavior. Here is source: https://www.amazon.com/dp/B09SHH5FHJ?ref_=ppx_hzsearch_conn_dt_b_fed_asin_title_4

- Then since I was in it I tried AGS replacement too from this source. No difference in behavior. Amazon.com

- Next I read on TFP posts Thermal Regulator or internal bypass. I pulled TR and put in hot water and then very hot water >170deg and it never moved. It seems to have some glue on it and it looks like some epoxy possible factory to keep spring and clip. I gather maybe this device never worked?

- While I had it out I put a borescope into hole and I can see cap of bypass valve and its there and feels relatively solid.

- I ordered on aftermarket ARU unit for TR despite warnings as I could not get a Pentair unit quick anywhere. That unit starts to open at 120F and is wide open around 130F. Amazon.com

- Thought I solved it, put it in. Initial power up gave me service heater but no other red LEDs as before and also as before a power cycle got me back to my typical short cycling.

- I have the bypass on order but have my doubts

- In the mean time I put a meter on ever sensor output to see if any were momentarily opening but I don’t see in contact open except the pressure switch which I can get to open if I turn off pump while heater running (as a means to test). All others seem to stay closed and even my meter on fast hold doesn’t detect a momentary open. These are latching? so no LED means no problems with them I would guess?

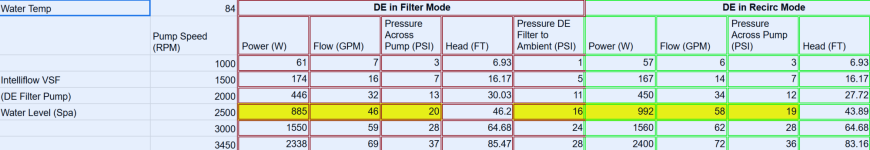

- This short cycling will occur when the in pool or spa more and that’s with the VSF pump registering 27GPM for pool or higher for spa at like 45GPM (SPA is elevated some 4 feet or so and this is through a freshly cleaned and serviced DE filter 48, plot below as I go between heat in spa and pool mode testing and timing short cycles and looking at stack flow temp. Both modes do same thing.

- The air is always moving and there is suction into white area at all times even , though the heating is in these modes cuts out, I can put my hand over exhaust and feel air but its clearly cooler when heat cycles off.

- These short cycles are running from 30 seconds to about 100 seconds in the 15 short cycles or so I have timed or so.

- I notice no heating light on when it is heating which is not how a recall it in past operations, I thought I saw the amber heating LED when I first got it.

- Here is a plot of temp in spa over same time period overlaid:

- Once it gets hotter the curve flattens out and it talks much longer to get the last 10 degrees than the first.

- So I cant seem to correlate the stop of heat cycle to any state change. No LED seems to even flicker when heat stops.

- Also when heat starts and then stops I have held the button to get stack temp and its reads like its is still rising and is low at the instant heat stops. It the nearly one minute its heating stack temp will start low and then slowly rise. At the instant it stops it’s at around 225. On longer cycles as hot at 250. If I use IR gun on black vent I’ll get close at like 230. When I watch temp its aways rising until it cuts out heat and exhaust still blows but blows like ambient air.

- If I let the heater cool for an hour or so, it I disconnect the SFS I read ~1-1.2Megaohms. I am in Florida, it’s a 95deg day and its in a black pipe so I figure could be right.

Attachments

Last edited: