Can you report the readings for Flow, Pressure, RPM and Watts at the different speeds?

Knocking/Hammer/Thumping noise from pipes when pool pump shuts off

- Thread starter Cartman269

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Jan 1, 2024

- 15

- Pool Size

- 8000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-30

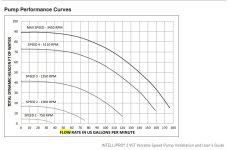

Unfortunately the pump is an IntelliPro 2 VST and does not show flow on the display. I have a chart in the manual for flow but it shows the graph in total head feet for flow, not sure what that measurement would be, however for the pool alone (without solar), it is an in-ground 6' on the deep end approximately 40 feet from the pump equipment. With solar on, the solar panels are 20' above the pool equipment at the highest point and 12' at the lowest as the solar pvc pipes run along the roof. The panels are approximately 85 liner feet from the pool equipment with a total of 7, 90 degree bends in both the supply and return piping. Not sure if that's too much information, but better to have it and not need it than the other way around, lol. I have attached a copy of the flow chart.Can you report the readings for Flow, Pressure, RPM and Watts at the different speeds?

The readings I can give you are as follows

Solar Panels On

Pressure - 18 psi

RPM - 2,450

Watts - 934

Solar Panels Off

Pressure - 8 psi

RPM - 1,700

Watts - 319

- Jan 1, 2024

- 15

- Pool Size

- 8000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-30

I have dropped my pump down to 1,000 rpm when solar is not in use. The flow light on the SWG is still lit and the weir is still open with water flowing over it. The pump is now using 70 watts instead of the 300+ watts it was using at 1,700 rpm. I am hesitant to go much lower, as I can’t see saving much more power and things seem to be working ok. Thanks for the tip, my electric bill will certainly be better!A calculator is not necessary. There is no turnover requirement for a residential pool. There are only a couple of factors to consider depending on how you run your pool and the equipment you have.

1) SWG - RPM needs to be high enough to trip the flow switch. But that is usually pretty low RPM for most setups. I would try 1000 RPM and see if the SWG still works.

2) Skimming - Find the lowest RPM where water travels over the weir door instead of around the sides. This will have a higher surface velocity so that skimming is more effective.

3) Heating - For you this is probably not a factor at all since you have solar but some heaters require a certain flow rate or pressure to operate properly.

The idea here is run at as low an RPM as possible to keep energy use as low as possible. I suspect you can operate well below the current 1750 RPM without any impact.

- May 3, 2007

- 18,076

- Pool Size

- 20000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite (T-15)

For most VS pumps, there is very little benefit going much lower than around 1000 RPM due to a constant drive electronics power.

An added benefit, is that you will probably not hear the thumping anymore with or without a new check valve.

An added benefit, is that you will probably not hear the thumping anymore with or without a new check valve.

Thread Status

Hello , This thread has been inactive for over 60 days. New postings here are unlikely to be seen or responded to by other members. For better visibility, consider Starting A New Thread.