- May 3, 2007

- 18,067

- Pool Size

- 20000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite (T-15)

I am currently on my 3rd T-15 SWG cell for an 18 year old pool. The 1st cell lasted about 9 years and the 2nd about 4 years and just passed year 4 on the 3rd cell. I thought it might be useful to document this cell's behavior as it is going through the last stages of useful life. As time goes on I will update this post to reflect current status.

Early last year, I started to notice some odd readings from my "clean" cell. The average salt level was still reading close to what my Taylor test kit was reading (~3000 ppm) but after several minutes of running, the instantaneous salt level dropped to ~2500 ppm. Given the cell was close to 3 yrs old at the time, I suspected it was nearing end of life. Also, when I did an acid cleaning (1:5), I noticed that there was black dust left behind, perhaps some sort of oxidation. However, the cell did pass the pool store test so I could not file a warranty claim at that time and the warranty ran out soon after.

You might be asking yourself how the average salt can be that much higher than the instantaneous salt level. I believe this can be explained by the fact that when the SWG first starts, the amp level is initially much higher which means that the reported salt level is also higher and the unit probably takes a measurement sample shortly after SWG start. After 30 minutes of run time, the instantaneous salt level has dropped off significantly so there must be some type of adverse reaction (e.g. oxidation) going on at the cell plates that is reducing the current.

Jumping forward to this week, the average salt is now reading 2600 ppm with the test kit at 3200 ppm and instantaneous salt reading of 2000 ppm on both polarities. So definitely declining but not completely dead. Once the average salt decreases to 2400 ppm, the unit will alarm and shut off but by then I plan on changing the cell type to a T-5 to see if I can keep it going. Because the plate surface is failing which reduces current, less FC is being generated as time goes on. But at least I can compensate for this with longer SWG run times, up to a point.

But before continuing on with the 3rd cell, I thought I would first try to extend the life of my 2nd cell which is in even worse condition than the 3rd so I swapped these cells. On the plus polarity of the cell, the SWG has a instantaneous salt reading of 1800 ppm and with negative polarity, a 1400 ppm instantaneous salt level. I plan on running this cell until the T-5 mode no longer works. After this cell is completely done, I will swap back to the 3rd cell and do the same thing. I am interested in seeing how much extra life I can squeeze out of these two cells.

T-5 mode has been running for several days now and it seems to be working ok. The amps are +4.65/-3.5 which are quite low for 3200 ppm of salt level and the FC generated seems to be much lower than what I would expect from that amp level so I suspect the efficiency has reduced quite a bit which is to be expected.

[WEEK 2 - Cell#2]

T-5 Mode has been running for two weeks now without incident. The amps have dropped a bit to +4.2/-3.2. Run time is 12 hours at 50% with FC at around 5 ppm CYA at 70 ppm so I am upping that to a 75% setting to get it a little higher for margin.

[WEEK 4 - Cell#2]

Still on T-5 Mode with cell#2. Amps have dropped about 10% or so and efficiency has dropped as well. I am now running at 75% for 24hr with a FC at 6.5 so much less production than 2 weeks ago. Once I can no longer maintain FC of 10% CYA, I will need to move back to cell#3. I don't suspect it will be much longer.

[WEEK 6 - Cell#2]

Still on T-5 Mode with cell#2. Amps are now -2.5A/+3.5A and cell efficiency has dropped off significantly. The cell is maintaining a FC of 5.5 ppm with a CYA of 70 ppm or around 8%. This is at 90% setting with 24hr run time so a significant drop in production. I don't think I will be able to maintain sufficient FC levels for much longer. If it gets down to 5% of CYA or I start seeing water clarity issues, I will move on to cell #3 and call this one over and done.

[WEEK 8 - Cell#2]

Amps have dropped to -1.5A/+3A and the salt level is now reading below 2400 ppm so the cell is now shutting off. An 8 week extension isn't too bad for a cell that was in pretty rough shape. The cell was collecting a lot of calcium mush and needed frequent cleaning. In the end, I am not sure it is worth the effort and the additional runtime cost since I am tier 4 at $0.40/kwh but we will see what cell #3 does. I will be running cell #3 in T-15 mode until the amps drop below 5.

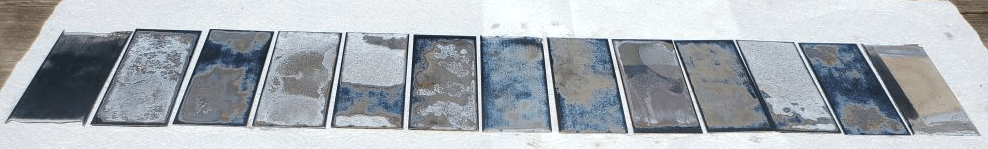

Cell pics are here:

www.troublefreepool.com

www.troublefreepool.com

[WEEK 2 - Cell#3]

Cell #3 has now been operating in T-15 Mode @ 45%/24hr for about 2 weeks now and cell amps are at -4.7A/+4.9A so much more balanced than Cell #2. FC is 6 ppm so over twice the production rate as Cell #2 at EOL which is consistent with the amperage and % settings. This Cell #3 was in better starting condition than was Cell #2 and I suspect it will last longer than Cell #2 did.

[WEEK 6 - Cell#3]

Cell #3 has now shut off due to low salt on T-15 Mode. What is interesting is that during the past week, the average salt level has been toggling between 2400 and 2300 ppm depending on which polarity it was running on. So it appears that the unit does not shut down until both polarities are below the 2400 ppm threshold. Current right now is running about -3.8A/+4.2A. I have now switched over to T-5 Mode and it is running once again. I am not yet getting the calcium mush like I was with Cell#2 but I suspect that will eventually happen as the Cell#3 gets closer to EOL.

[WEEK 14 - Cell#3]

With the drop in temperatures and solar elevation, FC usage has gone way down so the cell is operating pretty much the same as it was 8 weeks ago. So I suspect that it will last well into next season.

[Month 10 - Cell#3]

The old T-15 cell running in T-5 mode has finally been replaced after about 10 months of operation in T-5 mode. At the time of replacement, it was operating at about 3.35A of current and salt readings from the unit were getting close to the shut down threshold of 2400 ppm so I wanted to replace the cell before it shut off to avoid operation without the SWG in order to assess production rates.

The operational age of the cell in T-15 mode was around 50 months so an additional 10 months of operation in T-5 mode increased the lifespan by 20% which is not too bad.

When I replaced the cell, current went from 3.35A up to 6.31A and a week later FC levels went from 7.5 ppm to 9 ppm even with a change in SWG setting from 90% for the old cell to 45% for the new cell with the same pump run time (24hr). With the old cell, FC/CYA was 12.5% while with the new cell, it FC/CYA now 15%. A couple of weeks before the transition, I intentionally targeted a higher FC/CYA than was really needed to make sure there was nothing growing in the water so I could better estimate the production rate change.

By my estimate the cell production rate ratio of old/new was about 0.42 and since the old/new cell current ratio was 0.53, the efficiency of the cell must have dropped by an additional 20% that cannot be explained by just the current alone. Probably additional side reactions that are favored with the plates losing some of the catalytic characteristics due to degradation.

Early last year, I started to notice some odd readings from my "clean" cell. The average salt level was still reading close to what my Taylor test kit was reading (~3000 ppm) but after several minutes of running, the instantaneous salt level dropped to ~2500 ppm. Given the cell was close to 3 yrs old at the time, I suspected it was nearing end of life. Also, when I did an acid cleaning (1:5), I noticed that there was black dust left behind, perhaps some sort of oxidation. However, the cell did pass the pool store test so I could not file a warranty claim at that time and the warranty ran out soon after.

You might be asking yourself how the average salt can be that much higher than the instantaneous salt level. I believe this can be explained by the fact that when the SWG first starts, the amp level is initially much higher which means that the reported salt level is also higher and the unit probably takes a measurement sample shortly after SWG start. After 30 minutes of run time, the instantaneous salt level has dropped off significantly so there must be some type of adverse reaction (e.g. oxidation) going on at the cell plates that is reducing the current.

Jumping forward to this week, the average salt is now reading 2600 ppm with the test kit at 3200 ppm and instantaneous salt reading of 2000 ppm on both polarities. So definitely declining but not completely dead. Once the average salt decreases to 2400 ppm, the unit will alarm and shut off but by then I plan on changing the cell type to a T-5 to see if I can keep it going. Because the plate surface is failing which reduces current, less FC is being generated as time goes on. But at least I can compensate for this with longer SWG run times, up to a point.

But before continuing on with the 3rd cell, I thought I would first try to extend the life of my 2nd cell which is in even worse condition than the 3rd so I swapped these cells. On the plus polarity of the cell, the SWG has a instantaneous salt reading of 1800 ppm and with negative polarity, a 1400 ppm instantaneous salt level. I plan on running this cell until the T-5 mode no longer works. After this cell is completely done, I will swap back to the 3rd cell and do the same thing. I am interested in seeing how much extra life I can squeeze out of these two cells.

T-5 mode has been running for several days now and it seems to be working ok. The amps are +4.65/-3.5 which are quite low for 3200 ppm of salt level and the FC generated seems to be much lower than what I would expect from that amp level so I suspect the efficiency has reduced quite a bit which is to be expected.

[WEEK 2 - Cell#2]

T-5 Mode has been running for two weeks now without incident. The amps have dropped a bit to +4.2/-3.2. Run time is 12 hours at 50% with FC at around 5 ppm CYA at 70 ppm so I am upping that to a 75% setting to get it a little higher for margin.

[WEEK 4 - Cell#2]

Still on T-5 Mode with cell#2. Amps have dropped about 10% or so and efficiency has dropped as well. I am now running at 75% for 24hr with a FC at 6.5 so much less production than 2 weeks ago. Once I can no longer maintain FC of 10% CYA, I will need to move back to cell#3. I don't suspect it will be much longer.

[WEEK 6 - Cell#2]

Still on T-5 Mode with cell#2. Amps are now -2.5A/+3.5A and cell efficiency has dropped off significantly. The cell is maintaining a FC of 5.5 ppm with a CYA of 70 ppm or around 8%. This is at 90% setting with 24hr run time so a significant drop in production. I don't think I will be able to maintain sufficient FC levels for much longer. If it gets down to 5% of CYA or I start seeing water clarity issues, I will move on to cell #3 and call this one over and done.

[WEEK 8 - Cell#2]

Amps have dropped to -1.5A/+3A and the salt level is now reading below 2400 ppm so the cell is now shutting off. An 8 week extension isn't too bad for a cell that was in pretty rough shape. The cell was collecting a lot of calcium mush and needed frequent cleaning. In the end, I am not sure it is worth the effort and the additional runtime cost since I am tier 4 at $0.40/kwh but we will see what cell #3 does. I will be running cell #3 in T-15 mode until the amps drop below 5.

Cell pics are here:

Failing T-15 SWG Cell Experiment

I am currently on my 3rd T-15 SWG cell for an 18 year old pool. The 1st cell lasted about 9 years and the 2nd about 4 years and just passed year 4 on the 3rd cell. I thought it might be useful to document this cell's behavior as it is going through the last stages of useful life. As time goes...

[WEEK 2 - Cell#3]

Cell #3 has now been operating in T-15 Mode @ 45%/24hr for about 2 weeks now and cell amps are at -4.7A/+4.9A so much more balanced than Cell #2. FC is 6 ppm so over twice the production rate as Cell #2 at EOL which is consistent with the amperage and % settings. This Cell #3 was in better starting condition than was Cell #2 and I suspect it will last longer than Cell #2 did.

[WEEK 6 - Cell#3]

Cell #3 has now shut off due to low salt on T-15 Mode. What is interesting is that during the past week, the average salt level has been toggling between 2400 and 2300 ppm depending on which polarity it was running on. So it appears that the unit does not shut down until both polarities are below the 2400 ppm threshold. Current right now is running about -3.8A/+4.2A. I have now switched over to T-5 Mode and it is running once again. I am not yet getting the calcium mush like I was with Cell#2 but I suspect that will eventually happen as the Cell#3 gets closer to EOL.

[WEEK 14 - Cell#3]

With the drop in temperatures and solar elevation, FC usage has gone way down so the cell is operating pretty much the same as it was 8 weeks ago. So I suspect that it will last well into next season.

[Month 10 - Cell#3]

The old T-15 cell running in T-5 mode has finally been replaced after about 10 months of operation in T-5 mode. At the time of replacement, it was operating at about 3.35A of current and salt readings from the unit were getting close to the shut down threshold of 2400 ppm so I wanted to replace the cell before it shut off to avoid operation without the SWG in order to assess production rates.

The operational age of the cell in T-15 mode was around 50 months so an additional 10 months of operation in T-5 mode increased the lifespan by 20% which is not too bad.

When I replaced the cell, current went from 3.35A up to 6.31A and a week later FC levels went from 7.5 ppm to 9 ppm even with a change in SWG setting from 90% for the old cell to 45% for the new cell with the same pump run time (24hr). With the old cell, FC/CYA was 12.5% while with the new cell, it FC/CYA now 15%. A couple of weeks before the transition, I intentionally targeted a higher FC/CYA than was really needed to make sure there was nothing growing in the water so I could better estimate the production rate change.

By my estimate the cell production rate ratio of old/new was about 0.42 and since the old/new cell current ratio was 0.53, the efficiency of the cell must have dropped by an additional 20% that cannot be explained by just the current alone. Probably additional side reactions that are favored with the plates losing some of the catalytic characteristics due to degradation.

Last edited: