- Jun 9, 2021

- 79

- Pool Size

- 17500

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite (T-15)

Def a low pressure line, 8” WC or ~1/4 psi.Need to see the setup but at one end of the pipe you want to have a manifold with a pressure gauge that can read in 1/2 psi increments typically up to 30psi. You can find many gauges like that for fairly cheap. You also want to have a 1/4 turn shut off valve there so you can fine tune the pressure. Then at the other end you'll need some kind of adapter on a manifold to fill the line with compressed air. If you can get a hold of a pancake compressor then you can probably rig up some quick disconnect type fittings for filling. You can also simply cap one side of the line and put everything on the manifold with the pressure gauge. Whatever works best for you.

If the NG line is oprating at low pressure (0.5 psi or less), then it needs to hold 5psi air pressure for a minimum of 30mins with no drop. If the NG line is operating between 0.5 - 5.0 psi (high pressure gas line), then it needs to hold 1.5 times its operating pressure for 30mins with no drop. You should check local regulations in CA to see if there any stricter requirements.

While under pressure you can take a mixture of dish soap and water (mix it gently and don't make it bubbly) and flood every glued joint and manifold joint with it. If you see bubbles form around any of the glue joints, you have a leak. There's a commercial product called "Snoop" by Swagelok that is also a bubbling solution but it's really not worth it. Dish soap and water works fine.

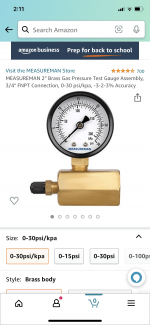

Was thinking something like this with the other end of line capped off. I think I can pump air in directly through this gauge.