@mooseau

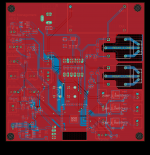

thanks for asking - my first set of bespoke boards arrive via FedEx later on this week. The design mostly worked on my jerry-rigged boards at the end of the summer but not perfectly - i think loose connections were to blame. The bespoke board should resolve that.

I have built in ports for pressure sensors, but don't intend to use them myself and all my pressure transducers are deployed elsewhere. the current board will handle dosing and measurement. it has PWM outputs for controlling a VFD and PWM outputs and current sensing for 'controlling' a chlorine generator. I've not yet built a board for the actual control of a chlorine generator. I do have the rudiments of a design and I know it will need a micro-controller to do the current measurement and PWM output (hence the other board having this functionality). But on the whole I don't want the two boards to be on the same copper as the current/power handling requirements for the chlorine generator board are very significantly higher and may need a higher density copper substrate (which adds significantly to the cost of fabrication - US5 vs US47 for 10 boards. the cost differential slightly diminishes after that.

Happy to share the design if people would like to critique. there should be another couple of chances for iterative improvement before my pool needs to be opened. And before that I have to break out mountains of concrete to re-plumb the skimmers.

thanks for asking - my first set of bespoke boards arrive via FedEx later on this week. The design mostly worked on my jerry-rigged boards at the end of the summer but not perfectly - i think loose connections were to blame. The bespoke board should resolve that.

I have built in ports for pressure sensors, but don't intend to use them myself and all my pressure transducers are deployed elsewhere. the current board will handle dosing and measurement. it has PWM outputs for controlling a VFD and PWM outputs and current sensing for 'controlling' a chlorine generator. I've not yet built a board for the actual control of a chlorine generator. I do have the rudiments of a design and I know it will need a micro-controller to do the current measurement and PWM output (hence the other board having this functionality). But on the whole I don't want the two boards to be on the same copper as the current/power handling requirements for the chlorine generator board are very significantly higher and may need a higher density copper substrate (which adds significantly to the cost of fabrication - US5 vs US47 for 10 boards. the cost differential slightly diminishes after that.

Happy to share the design if people would like to critique. there should be another couple of chances for iterative improvement before my pool needs to be opened. And before that I have to break out mountains of concrete to re-plumb the skimmers.