Hi All!

Yes I know this has been beat to death, but I do have some questions before I dive into purchasing a system. I have read the threads on Intelliflo Automation by MyAZPool, and the reveiws also. I j=have just about read everything I could get my hands on also. Yes to me if is a little confusing. But here is what I want. An automation system that myself and my wife can control pretty easy, Set the pool heat or the spa heat and have the valves move accordingly ( which we have now) also turn on the spa blower wireless if possible. As far as my valves I have a intake and return valve, (automated) but I also have 3 other valves that I would like to automate to close or open to direct most of the flow to my Polaris 360 in the morning then open to the pool after about an hour. This way the Polaris can do it's thing and I can keep the pump running at around 2700 RPM then drop it down to 1800 for the remainder of the day. I would also like to control the water feature which is a separate pump Since I am going all out I might as well go for the salt system too. Right now I am looking at the:

52190

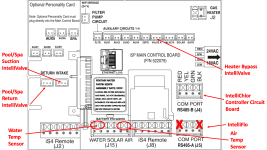

IntelliCenter System Load Center i8PS, IC40, Common Load Center (w/ Salt) -- Model Code: 5PSIC40 (includes 2 IntelliValves).

Reading and reviewing the posts on here, I am a little confused on what is standard and what the aux circuits are. So I have Master Temp 400 Heater, Intelliflo Filter Pump, Waterfall Pump, Spa Blower and 4 valves, plus the Intellichlor and two lights ( 1 Ea Pool/Spa). So I assume the Heater Filter Pump is one circuit, and everything else with the exception of the valves is on it's own circuit? Am I correct on this? That would make six circuits which would leave me two extra? Thanks for any and all help with this. As those of you who have purchased one this is a huge investment, I just want to make sure I understand what it is I am purchasing so I can make an informed decision. If I left out any information or if you have questions fire away please. Thanks in advance.

Yes I know this has been beat to death, but I do have some questions before I dive into purchasing a system. I have read the threads on Intelliflo Automation by MyAZPool, and the reveiws also. I j=have just about read everything I could get my hands on also. Yes to me if is a little confusing. But here is what I want. An automation system that myself and my wife can control pretty easy, Set the pool heat or the spa heat and have the valves move accordingly ( which we have now) also turn on the spa blower wireless if possible. As far as my valves I have a intake and return valve, (automated) but I also have 3 other valves that I would like to automate to close or open to direct most of the flow to my Polaris 360 in the morning then open to the pool after about an hour. This way the Polaris can do it's thing and I can keep the pump running at around 2700 RPM then drop it down to 1800 for the remainder of the day. I would also like to control the water feature which is a separate pump Since I am going all out I might as well go for the salt system too. Right now I am looking at the:

52190

IntelliCenter System Load Center i8PS, IC40, Common Load Center (w/ Salt) -- Model Code: 5PSIC40 (includes 2 IntelliValves).

Reading and reviewing the posts on here, I am a little confused on what is standard and what the aux circuits are. So I have Master Temp 400 Heater, Intelliflo Filter Pump, Waterfall Pump, Spa Blower and 4 valves, plus the Intellichlor and two lights ( 1 Ea Pool/Spa). So I assume the Heater Filter Pump is one circuit, and everything else with the exception of the valves is on it's own circuit? Am I correct on this? That would make six circuits which would leave me two extra? Thanks for any and all help with this. As those of you who have purchased one this is a huge investment, I just want to make sure I understand what it is I am purchasing so I can make an informed decision. If I left out any information or if you have questions fire away please. Thanks in advance.