So I ran out of time and patience as I put in the new pump and filter. Yes, someone keeps saying it on here, I'm going to give a shout out. That Intelliflo3 is QUIET!!!

I have such a small area to work with. And I didn't get all my bypass and heater stuff done. but I need the water circulating. So I did not install my SWCG (I can't use it anyway, just resurfaced.) Basically, I just did a temporary Filter-out and ran it to the out-to-pool line. I did it with enough height that I can cut and reuse.

So here's what I'm thinking. Autobots, transform and move out!

The pump is built with unions at the inlet and outlet.

The filter is built with unions at the inlet and outlet.

The heater is built with unions at the inlet and outlet.

I imagine the heater bypass is not used very often. I didn't have one for the last 20 years. Though there were a few times I wish I did, when the heater wasn't working, and after the resurface when too much plaster dust is coming through, and probably now with a little bit of pvc dust from cutting. So what if the bypass was more of a complete removal.

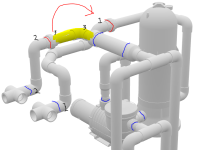

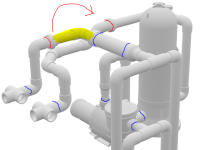

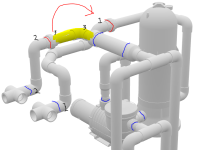

In the attached photo, the blue are unions I mentioned before. The layout as it is runs from the filter up, and then towards the heater with a tiny drop in elevation, then from the heater up and over, to the (future) RJ60 or IC40, and then out to the pool.

The red are unions I would add. That would create 3 puzzle pieces.

1 - going from the filter to the heater inlet - could be removed and stored or placed on the side. Can cap the heater inlet.

2 - going from the heater outlet to the SWCG - could be removed and stored or placed on the side. Can cap the heater outlet.

3 - (yellow) can be rotated 180 so that the from the filter now goes directly out to the diverter valve.

Voilà. Bypass, with possibly improved flow because less tees and elbows, and less clutter.

So, genius or insanity?

I have such a small area to work with. And I didn't get all my bypass and heater stuff done. but I need the water circulating. So I did not install my SWCG (I can't use it anyway, just resurfaced.) Basically, I just did a temporary Filter-out and ran it to the out-to-pool line. I did it with enough height that I can cut and reuse.

So here's what I'm thinking. Autobots, transform and move out!

The pump is built with unions at the inlet and outlet.

The filter is built with unions at the inlet and outlet.

The heater is built with unions at the inlet and outlet.

I imagine the heater bypass is not used very often. I didn't have one for the last 20 years. Though there were a few times I wish I did, when the heater wasn't working, and after the resurface when too much plaster dust is coming through, and probably now with a little bit of pvc dust from cutting. So what if the bypass was more of a complete removal.

In the attached photo, the blue are unions I mentioned before. The layout as it is runs from the filter up, and then towards the heater with a tiny drop in elevation, then from the heater up and over, to the (future) RJ60 or IC40, and then out to the pool.

The red are unions I would add. That would create 3 puzzle pieces.

1 - going from the filter to the heater inlet - could be removed and stored or placed on the side. Can cap the heater inlet.

2 - going from the heater outlet to the SWCG - could be removed and stored or placed on the side. Can cap the heater outlet.

3 - (yellow) can be rotated 180 so that the from the filter now goes directly out to the diverter valve.

Voilà. Bypass, with possibly improved flow because less tees and elbows, and less clutter.

So, genius or insanity?