Hello, I've found these forums to be invaluable after becoming a pool owner several years ago so I just wanted to say thank you to all the knowledgeable posters who help out the rest of us here. I've come once again with a new issue and any advice would be greatly appreciated.

There is a large suction side leak underneath the middle of my pool equipment pad most likely from tree roots (a large redwood tree is located about 7 feet from the pad). Rather than have the damaged line repaired (relatively expensive IMO) we're considering tearing out the existing pad, removing all of the roots beneath it and replacing it with a new pad (costs more but a better long-term solution IMO).

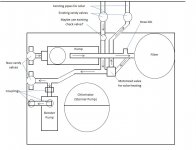

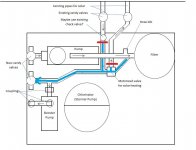

The original pipe routing (see attached pic) appears to have a lot of extraneous bends so I'm hoping to take the opportunity to simplify the layout for better flow. I'm also thinking it might be good to keep all of the incoming/outgoing plumbing near the edge of the pad so that they can be more easily accessed if there is another problem in the future. I've taken measurements and drawn up the following scaled layout but I'm no expert so any suggestions or advice would be greatly appreciated.

PS - Does anyone know why some of the existing plumbing is routed to dip under the pad only to pop back up a few inches away? Seems like a lot of unnecessary bends but maybe there is a good reason?

PPS - The offending redwood tree is located off the bottom right corner of the diagram.

There is a large suction side leak underneath the middle of my pool equipment pad most likely from tree roots (a large redwood tree is located about 7 feet from the pad). Rather than have the damaged line repaired (relatively expensive IMO) we're considering tearing out the existing pad, removing all of the roots beneath it and replacing it with a new pad (costs more but a better long-term solution IMO).

The original pipe routing (see attached pic) appears to have a lot of extraneous bends so I'm hoping to take the opportunity to simplify the layout for better flow. I'm also thinking it might be good to keep all of the incoming/outgoing plumbing near the edge of the pad so that they can be more easily accessed if there is another problem in the future. I've taken measurements and drawn up the following scaled layout but I'm no expert so any suggestions or advice would be greatly appreciated.

PS - Does anyone know why some of the existing plumbing is routed to dip under the pad only to pop back up a few inches away? Seems like a lot of unnecessary bends but maybe there is a good reason?

PPS - The offending redwood tree is located off the bottom right corner of the diagram.