Hi, I am getting ready to start our pool build, and had a couple of questions on how many pool returns to use, and how this works with the Spa. Hoping somebody can help out, as we excavate on Monday. Have searched for this, but did not see anything that related to placement based on this type of pool shape. Some background: 20k pool, 525 Sqft, 110' perimeter, 6'x6' Spa, Pentair VS pump, 520 sqft filter, 400k heater. Running a pool & Spa off single Vs. pump (Pool/Spa combo).

Plumbing: 2" looped pool return line, 2" dedicated pool drain line, 2 skimmers each on dedicated 2" line (3 x 2" suction lines total), 3" Spa drain line. 2.5" Spa jet looped line, 2" Air return (to spa), 5 Spa jets total. 6 Deck jets, 1 bubbler in the tanning ledge. Pool is ~23' from equipment pad, Spa is ~40' from equipment pad. With two turnovers / day, the estimated pool return flow is 27 GPM (20000 / 24 / 60). With 7 returns, that's ~4 GPM per return.

QUESTIONS:

1. Do I need to run a separate pool return line to the Spa for filtering when in Pool mode, or do I just use the Spa jets for filtering by not closing the Pool/Spa return Jandy valve completely (i.e., pegged for 90% closed position)? Since filtered (& heated) water goes to the Spa jets and to the pool returns, depending on the position of the 3-way Jandy valve that switches between pool & spa mode, I wasn't sure if the Spa needed a separate pool return. Is there an advantage in doing it one way Vs. the other?

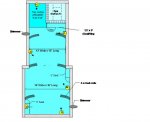

2. Given the pool shape in the attached JPG below, how many returns should I have and where should they be placed? It seems the rule of thumb is 2 at least 2 returns per skimmer, and the intent of return placement is to circulate the water past the skimmers to both mix/circulate sanitized water, and to skim off debris before it falls to the floor. That said, with an irregular pool shape and a tanning ledge are more returns needed? My plumber suggested 6 in the pool based on the pool shape + 1 in the Spa, but said the final placement is up to me. 7 returns sounds like a lot (lower GPM per return), but maybe not? Would appreciate some design input from plumbers or pool builders.

Thanks!

Pool Diagram:

Plumbing: 2" looped pool return line, 2" dedicated pool drain line, 2 skimmers each on dedicated 2" line (3 x 2" suction lines total), 3" Spa drain line. 2.5" Spa jet looped line, 2" Air return (to spa), 5 Spa jets total. 6 Deck jets, 1 bubbler in the tanning ledge. Pool is ~23' from equipment pad, Spa is ~40' from equipment pad. With two turnovers / day, the estimated pool return flow is 27 GPM (20000 / 24 / 60). With 7 returns, that's ~4 GPM per return.

QUESTIONS:

1. Do I need to run a separate pool return line to the Spa for filtering when in Pool mode, or do I just use the Spa jets for filtering by not closing the Pool/Spa return Jandy valve completely (i.e., pegged for 90% closed position)? Since filtered (& heated) water goes to the Spa jets and to the pool returns, depending on the position of the 3-way Jandy valve that switches between pool & spa mode, I wasn't sure if the Spa needed a separate pool return. Is there an advantage in doing it one way Vs. the other?

2. Given the pool shape in the attached JPG below, how many returns should I have and where should they be placed? It seems the rule of thumb is 2 at least 2 returns per skimmer, and the intent of return placement is to circulate the water past the skimmers to both mix/circulate sanitized water, and to skim off debris before it falls to the floor. That said, with an irregular pool shape and a tanning ledge are more returns needed? My plumber suggested 6 in the pool based on the pool shape + 1 in the Spa, but said the final placement is up to me. 7 returns sounds like a lot (lower GPM per return), but maybe not? Would appreciate some design input from plumbers or pool builders.

Thanks!

Pool Diagram: