I thought I would share my recent work with all of you. A little info..bought a house last month, it has a pool and raised spa, but no heating source for either.. I decided to go the solar route to start off.

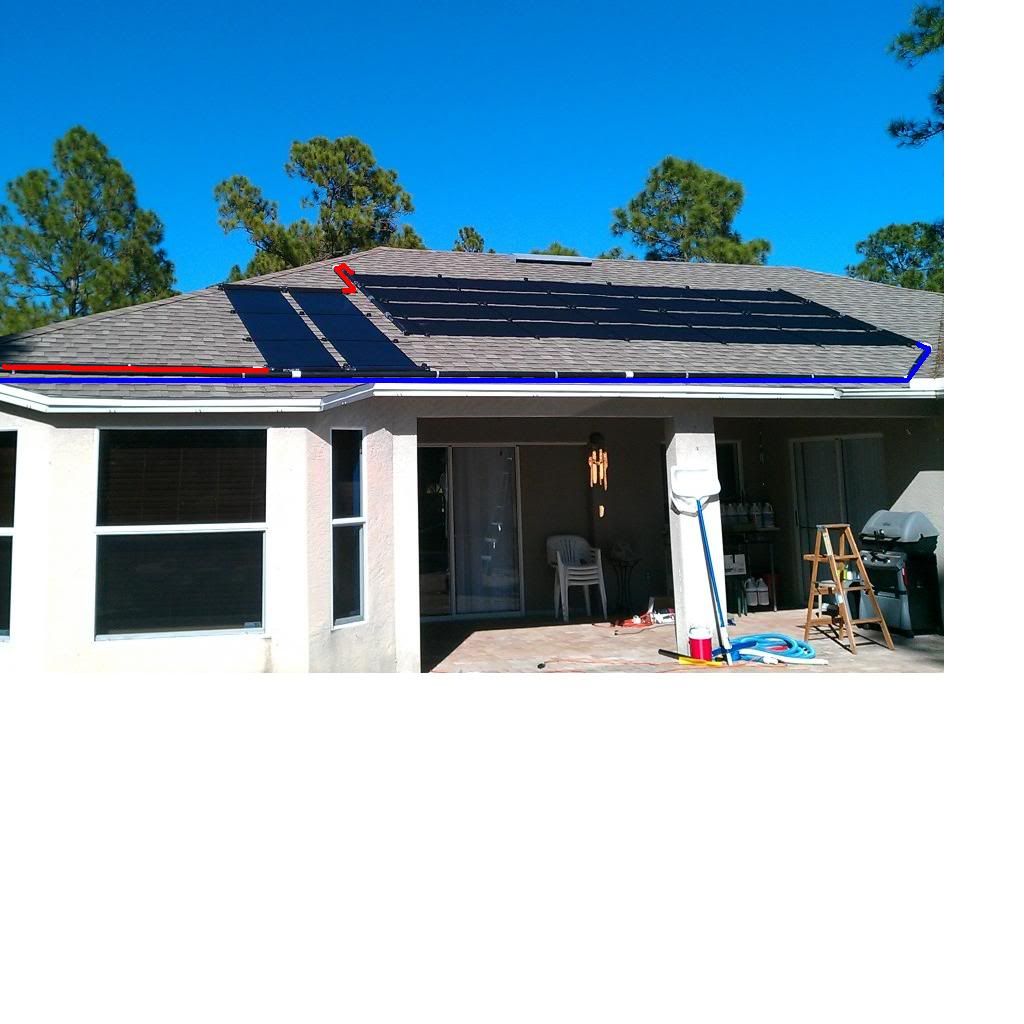

My dad and I got the my solar system all installed over the past two days. Between all the plumbing, 200 sq ft of FAFCO solar panels (Four 2'x20' panels and two 2'x10' panels) and all the misc. items for all the plumbing and installation etc.. I was able to get it all done for under $700. (got a great deal on panels from and end of year blowout sale).

Now I have heat and it is free from here on out.

Today is the first day I have run it and we have been a bit colder the past few days (upper 60s-low 70s during day and upper 40s to low 50s at night), so my water temp this morning was 62* in the pool and spa. I ran the solar for 3 hours from 9am to Noon recirculating both the pool and spa, and the pool temp rose up to 70*

I wanted to see how well it would heat just the spa so I switched it to the spa only and in less than two hours it has gone from 70* to 90*...outside air temp right now is 74*

We will see what it gets to by 4pm today

I am very happy so far.

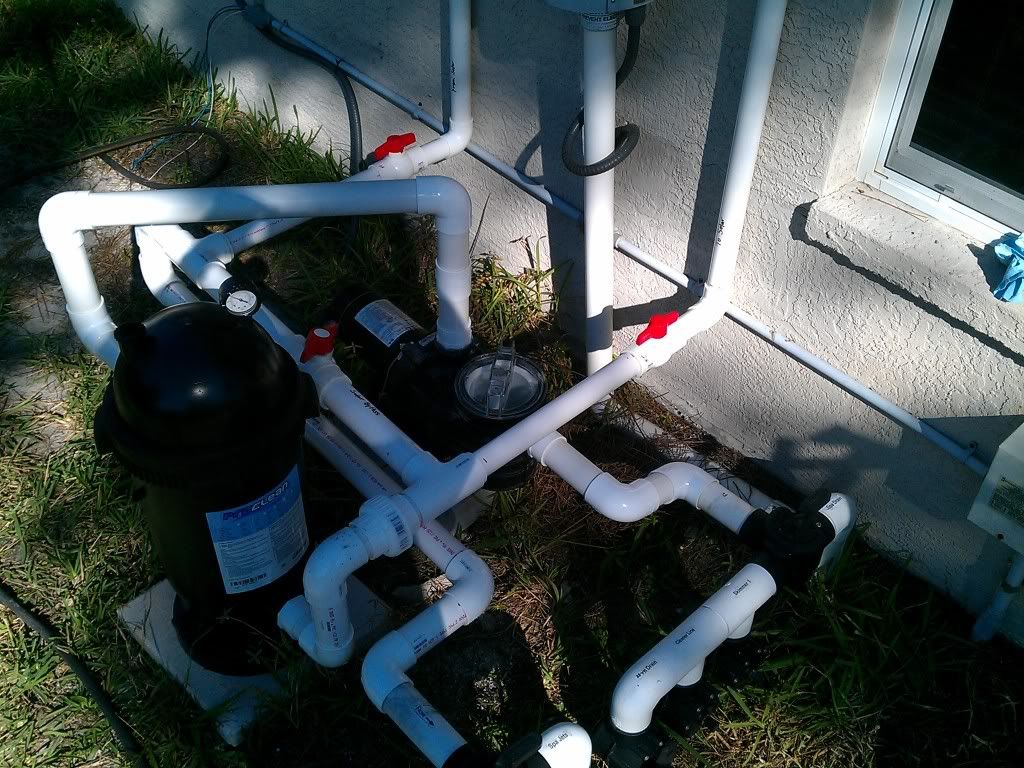

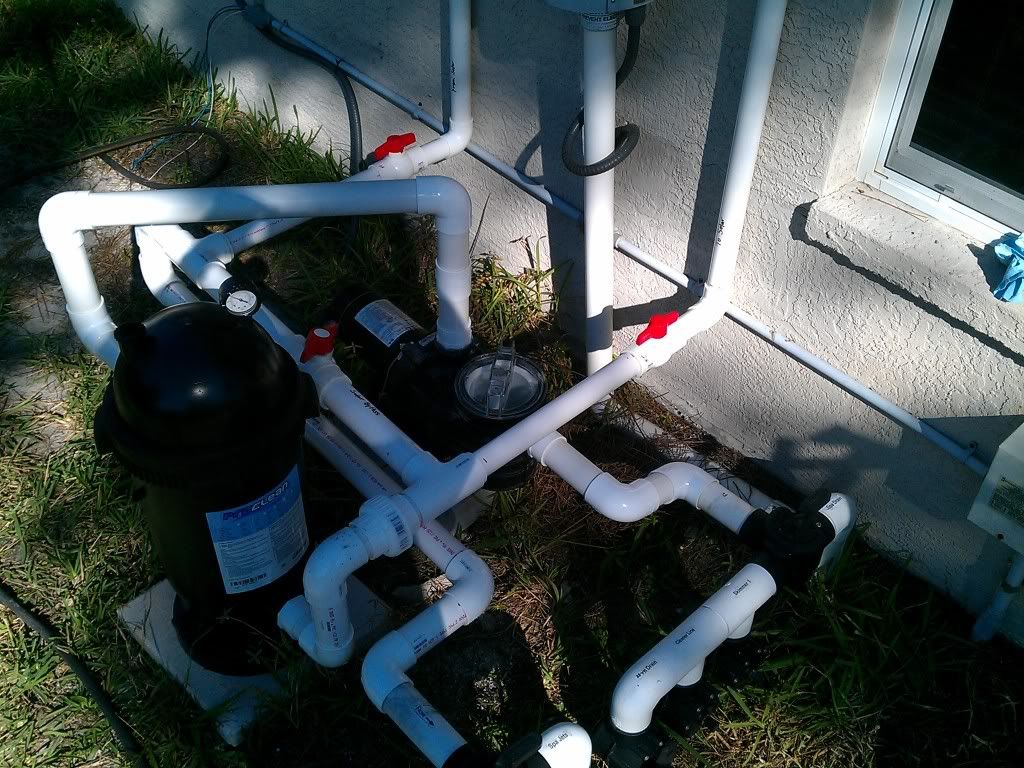

It isn't all completely done yet, I have some more clamps to install for all the plumbing running up the wall and the blower for the spa, and some bracing under an small section of the pipes. We plumbed it so that if I decide to get a heater I can hook it right up to my current layout and not have to change anything, so right now it just loops around and needs a little bracing under it for some extra support...which I currently just have a scrap piece of pipe with a T on top if it for temporary support.

here are few pictures of everything we did:

Now we can FINALLY use our pool and spa.. we haven't been able to use it since we moved in being water temps were always around 70* ... but not anymore!

My dad and I got the my solar system all installed over the past two days. Between all the plumbing, 200 sq ft of FAFCO solar panels (Four 2'x20' panels and two 2'x10' panels) and all the misc. items for all the plumbing and installation etc.. I was able to get it all done for under $700. (got a great deal on panels from and end of year blowout sale).

Now I have heat and it is free from here on out.

Today is the first day I have run it and we have been a bit colder the past few days (upper 60s-low 70s during day and upper 40s to low 50s at night), so my water temp this morning was 62* in the pool and spa. I ran the solar for 3 hours from 9am to Noon recirculating both the pool and spa, and the pool temp rose up to 70*

I wanted to see how well it would heat just the spa so I switched it to the spa only and in less than two hours it has gone from 70* to 90*...outside air temp right now is 74*

We will see what it gets to by 4pm today

I am very happy so far.

It isn't all completely done yet, I have some more clamps to install for all the plumbing running up the wall and the blower for the spa, and some bracing under an small section of the pipes. We plumbed it so that if I decide to get a heater I can hook it right up to my current layout and not have to change anything, so right now it just loops around and needs a little bracing under it for some extra support...which I currently just have a scrap piece of pipe with a T on top if it for temporary support.

here are few pictures of everything we did:

Now we can FINALLY use our pool and spa.. we haven't been able to use it since we moved in being water temps were always around 70* ... but not anymore!