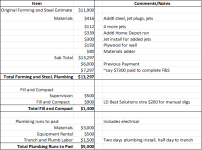

- Oct 25, 2015

- 5,189

- Pool Size

- 25000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- CircuPool RJ-60 Plus

Thanks all, it's been a while since I tested. Will get my new refills out and run a new set tonight. Wow, first test results for my new, well almost new pool!

Chris

Chris