Thanks for clarification. So, what brand should I use for salt water system and how to know what size to be used?A SaltWater Chlorine Generartor (salt water system) creates your chlorine on site. So the pool is sanitized with chlorine.

Concrete or fiberglass pool in Katy, Tx

- Thread starter nima katy

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- May 3, 2014

- 59,328

- Pool Size

- 6000

- Surface

- Fiberglass

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-40

Are you planning to use an automation system? What brand pump, etc did you plan to have?

I have this quote . Sorry I have very little or better say have no knowledge on the pool. I want to see what systems I need to have and what should i ask to have and what do I need to ask them to put in contractAre you planning to use an automation system? What brand pump, etc did you plan to have?

Attachments

-

Pool93_009.jpg548.5 KB · Views: 10

Pool93_009.jpg548.5 KB · Views: 10 -

Pool 93_001.jpg577.4 KB · Views: 10

Pool 93_001.jpg577.4 KB · Views: 10 -

Pool93_002.jpg359.3 KB · Views: 11

Pool93_002.jpg359.3 KB · Views: 11 -

Pool93_003.jpg300.5 KB · Views: 11

Pool93_003.jpg300.5 KB · Views: 11 -

Pool93_004.jpg292.7 KB · Views: 11

Pool93_004.jpg292.7 KB · Views: 11 -

Pool93_005.jpg363.4 KB · Views: 9

Pool93_005.jpg363.4 KB · Views: 9 -

Pool93_006.jpg381.9 KB · Views: 10

Pool93_006.jpg381.9 KB · Views: 10 -

Pool93_008.jpg495.6 KB · Views: 10

Pool93_008.jpg495.6 KB · Views: 10 -

Pool 93_007.jpg348.3 KB · Views: 11

Pool 93_007.jpg348.3 KB · Views: 11 -

Estimate.pdf191.1 KB · Views: 11

- May 3, 2014

- 59,328

- Pool Size

- 6000

- Surface

- Fiberglass

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-40

The EasyTouch is old tech. Pentair no longer manufactures them. They should be using an IntelliCenter.

Get the IntelliCenter with a SWCG included. I do not see a volume of the pool anywhere but be sure the SWCG is rated for well over 2X the pool volume.

Get the Intelliflo3 pump. The Superflo is underpowered and will be more expensive to run.

Get the IntelliCenter with a SWCG included. I do not see a volume of the pool anywhere but be sure the SWCG is rated for well over 2X the pool volume.

Get the Intelliflo3 pump. The Superflo is underpowered and will be more expensive to run.

pool volume shows about 12000 gal.The EasyTouch is old tech. Pentair no longer manufactures them. They should be using an IntelliCenter.

Get the IntelliCenter with a SWCG included. I do not see a volume of the pool anywhere but be sure the SWCG is rated for well over 2X the pool volume.

Get the Intelliflo3 pump. The Superflo is underpowered and will be more expensive to run.

We live in Katy, TX incase that potentially mpact any of the equipments selection:

so, what filter is suggested? Is it coming with salt water system how about valves?

What tiles are suggested to be used in salt water system?

so, what filter is suggested? Is it coming with salt water system how about valves?

What tiles are suggested to be used in salt water system?

Hello and thanks in advance for taking time to respond and help me in this costly feature purchase!

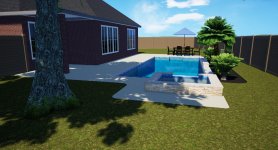

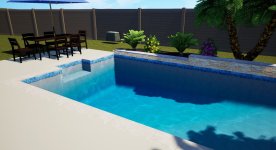

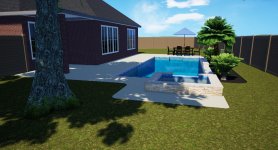

I am trying to get to finalize what do I need as far as equipments and details of the pool. As far as the shape and size, we are final with the attached pictures but need more information to be able to make a decision on the equipments, cleaning and filteration system, jets, LED, tiles, plaster, heater, plumbing, etc.

It seems salt water is a bit costlier at the begining but easier down the road so I probably would go with salt water system and whatever works with that. For heater, I am not going to heat the whole pool and just looking at warming up spa during the winter time. I have electric and gas available.

So far, I got some suggestion about Main pump to be Intelliflo3 pump and using IntelliCenter for screen logic automation(I am not sure if I need this upgrade at all)

I would appreciate any feedback for any system .

I am trying to get to finalize what do I need as far as equipments and details of the pool. As far as the shape and size, we are final with the attached pictures but need more information to be able to make a decision on the equipments, cleaning and filteration system, jets, LED, tiles, plaster, heater, plumbing, etc.

It seems salt water is a bit costlier at the begining but easier down the road so I probably would go with salt water system and whatever works with that. For heater, I am not going to heat the whole pool and just looking at warming up spa during the winter time. I have electric and gas available.

So far, I got some suggestion about Main pump to be Intelliflo3 pump and using IntelliCenter for screen logic automation(I am not sure if I need this upgrade at all)

I would appreciate any feedback for any system .

Attachments

-

Pool93_002.jpg359.3 KB · Views: 5

Pool93_002.jpg359.3 KB · Views: 5 -

Pool93_003.jpg300.5 KB · Views: 5

Pool93_003.jpg300.5 KB · Views: 5 -

Pool93_004.jpg292.7 KB · Views: 5

Pool93_004.jpg292.7 KB · Views: 5 -

Pool93_005.jpg363.4 KB · Views: 5

Pool93_005.jpg363.4 KB · Views: 5 -

Pool93_006.jpg381.9 KB · Views: 5

Pool93_006.jpg381.9 KB · Views: 5 -

Pool93_008.jpg495.6 KB · Views: 5

Pool93_008.jpg495.6 KB · Views: 5 -

Pool 93_007.jpg348.3 KB · Views: 5

Pool 93_007.jpg348.3 KB · Views: 5 -

Pool93_009.jpg548.5 KB · Views: 5

Pool93_009.jpg548.5 KB · Views: 5 -

Estimate.pdf191.1 KB · Views: 3

-

Pool 93_001.jpg577.4 KB · Views: 5

Pool 93_001.jpg577.4 KB · Views: 5

- May 3, 2014

- 59,328

- Pool Size

- 6000

- Surface

- Fiberglass

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-40

The IC 40 SWCG is a good fit

Filter quoted is fine.

All pool rated valves , tile, etc is fine. The ‘saltwater’ is not significant to the pool or equipment.

Filter quoted is fine.

All pool rated valves , tile, etc is fine. The ‘saltwater’ is not significant to the pool or equipment.

thanks for your quick responses!The IC 40 SWCG is a good fit

Filter quoted is fine.

All pool rated valves , tile, etc is fine. The ‘saltwater’ is not significant to the pool or equipment.

Doe the SWG define type of coping and tiles?

- May 3, 2014

- 59,328

- Pool Size

- 6000

- Surface

- Fiberglass

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-40

No. All pool use rated tile and coping will work.Doe the SWG define type of coping and tiles?

AQUA~HOLICS

In The Industry

Are you looking for any input on the construction aspect of the project and the design layout?

I would appreciate any input about the equipments and what would be a good option and matching , what is practical and same time not expensive, size of equipments, etc. Layout, we kind of chose what we want unless there is something would need to be consideredAre you looking for any input on the construction aspect of the project and the design layout?

@mknaussNo. All pool use rated tile and coping will work.

In the last 2-3 day I read a lot from different topics in TFP blog and learned more. I really appreciate you and owners/industry leaders like you for sharing your valuable knowledge with pool first time owners/to be owners like me

Based on the pool size that will be fitting in my backyard and your suggestions, I summarized the followings and I would appreciate any alternative that makes more sense or perform better.

Pool size: 14'WX33'L (3.5' to 5.5' water depth with gradient of maximum 3:1)

Pool about 480 square foot, 94 perimeter and about 12000 ga.

Spa: 31 sq.ft 12" rise

For SWG sanitizing system: IC 40 SWCG

Main Pump: Intelliflo3 pump (it is my understanding that this pump flow rate is 140gpm)

Filter: Pentair 420 Clean and Clear Cartridge(shouldnt have larger filter? if I understand correctly, this filter maximum flow rate is 150 gmp and filter shall be at least 20% larger than maximum flow rate of pump. So, should I have a filter with more than 168 gpm ?)

SPA Pump:????

SPA Jets:4

Pool cleaner: Aqua Products EVO 614i

Heater(just for spa): Ray-Pak 400K BTU; is there any advantage to use electrical?

Lighting:(2)Jandy LED changing light for pool and (1)for spa

Valves: Jandy never-lube

Pool Plumbing: 4” Pipe drainage to street; 2”(2.375”OD)Schedule 40 PVC, Type 1, Grade 1; Pump connectors to be schedule 40 as well?

Skimmers and main drains plumbed separately to Equipment. PVC to be painted to protect it from UV degradation.

No flexible hose to be used for plumbing.

Skimmer: (2) skimmer in windway(one per 400 square foot pool surface)

Returns: (4)returns for pool between 250-600 square foot. Having return lines to the sides of your pool in addition to the IFCS returns at the bottom

Pool Coping: Travertine Sq. edge(any issue with salt water?)

Facing: Travertine split-face

Electrical:??? bonding or grounding?

Any other item I am missing?

I will be posting another message for construction separately

I greatly appreciate your feedback. I am hoping I can finish the scope so I can get different bids by end of the month and proceed

Last edited:

- May 3, 2014

- 59,328

- Pool Size

- 6000

- Surface

- Fiberglass

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-40

Don't worry about all the flowrate stuff on the pump and filter. Does not matter. The pump will never pump more than that filter can manage.

The spa with only four jets likely does not need a separate spa pump. The Intelliflo (plumbed correctly) will easily handle 4 jets.

Pump connectors need to be pump rated unions.

Using natural stone around any pool requires it to be high quality or it will degrade.

The spa with only four jets likely does not need a separate spa pump. The Intelliflo (plumbed correctly) will easily handle 4 jets.

Pump connectors need to be pump rated unions.

Using natural stone around any pool requires it to be high quality or it will degrade.

Are you looking for any input on the construction aspect of the project and the design layout?

@AQUA~HOLICSAre you looking for any input on the construction aspect of the project and the design layout?

Here is what I learned and I would like to get some feedback from the experts here in this forum:

Pool size: 14'WX33'L (3.5' to 5.5' water depth with gradient of maximum 3:1)

Pool about 480 square foot, 94 perimeter and about 12000 ga.

Spa: 31 sq.ft 12" rise

SWG

GUNITE STRUCTURE

- Beam #4; Gunite (bond Beam) 12"x12” Pneumatically Applied @ 4000 P.S.I.

- Wall and floor #3 at 12” (up to 24” o.c) ; Gunite (Walls/Floor) 6" Pneumatically Applied @ 4000 P.S.I, 8” floor(some offer 6”)

Equipment Pad

- Ensure your equipment pad is large enough to allow maintenance - a 3x8 is sort of the norm but if you could bump that a little based on where it will be positioned it would help. Maybe a 3x9, 4x8 or 4x9. Especially if you may consider adding a chiller in the future you should plan for that on the pad now.

thank you very much!Don't worry about all the flowrate stuff on the pump and filter. Does not matter. The pump will never pump more than that filter can manage.

The spa with only four jets likely does not need a separate spa pump. The Intelliflo (plumbed correctly) will easily handle 4 jets.

Pump connectors need to be pump rated unions.

Using natural stone around any pool requires it to be high quality or it will degrade.

@mknauss Do you think I am in the right track for heater as well using gas? Also, any feedback on the electrical?

Last edited:

Are you looking for any input on the construction aspect of the project and the design layout?

@AQUA~HOLICSAre you looking for any input on the construction aspect of the project and the design layout?

Here is what I learned and I would like to get some feedback from the experts here in this forum:

Pool size: 14'WX33'L (3.5' to 5.5' water depth with gradient of maximum 3:1)

Pool about 480 square foot, 94 perimeter and about 12000 ga.

Spa: 31 sq.ft 12" rise

SWG

Note that the pool will be in Katy , Texas with expansive clay soil

GUNITE STRUCTURE Any feedback on below points? do they make sense? How can I ensure contractor will be following on the gunite mixture?

- Beam #4; Gunite (bond Beam) 12"x12” Pneumatically Applied @ 4000 P.S.I.

- Wall and floor #3 at 12” (up to 24” o.c) ; Gunite (Walls/Floor) 6" Pneumatically Applied @ 4000 P.S.I, 8” floor(some offer 6”)

PLASTER REQUIREMENT; Any feedback on below points? How can I ensure the contractor will be following guidelines for good quality plaster?

*The best cement/aggregate ratio is about one part cement to 1.5-1.75 parts aggregate (marble sand).

*When mixing plaster, a thick mix is best. Shoot for a water/cement ratio of .48 or less.

*if the plaster has been mixed for more than 90 minutes, the plaster mix should be discarded.

*Plaster should contain as little calcium chloride set-accelerant as possible and never more than 2 percent to the amount of white cement. (Colored plaster, of course, should not contain any calcium chloride as it will lighten the color and become blotchy.)

*Never add water to plaster surfaces while troweling.

*In extreme dry heat, tenting the pool, and perhaps even directing air from an evaporative cooler beneath the tent, will help the plaster retain its moisture, and properly cure and harden without cracking.

*Though conditions vary, water usually should not be added for at least six hours after the pool has been plastered and finished.

*Ensure tap or fill water is balanced with sufficient TA and CH before using to fill the pool.

*Before mixing any plaster it’s a good idea to have your water tested for metals such as Iron, Copper, or Manganese.

*On the day plaster is to be applied one should do their best to be onsite. Once mixed the crew has a limited period of time to apply the plaster or the product must be discarded.

EQUIPMENT PAD

- A 3'x8' pad is good enough or we should have larger?

I am planing to use SWG sanitizing system: IC 40 SWCG

Main Pump: Intelliflo3 pump

- All poured type concrete decking should have fiber mesh in the mix.

- Concrete decks have #3 rebar at 18” on centers for reinforcing.

- Concrete decks are 4" thick.

- Concrete type decks have deck dowels tied in from swimming pools.

- pre-saturation of the soil prior to pouring concrete. A common specification used by soils engineers is to attain a 110% to 120% of optimum moisture content to a depth of at least 18″

- minimum of four to six inches of crushed rock is highly recommended as a cushion under pool shell

AQUA~HOLICS

In The Industry

With expansive clay soil, request a steel engineering report that advises what is required for your specific pool.Gunite 6:1 cement(sacks)/sand(yard) ratio?? Is this correct?

GUNITE

4:1 mix is minimum for Gunite.

Gunite is mixed on site, unlike Shotcrete that is batched by a computer at a concrete yard within very strict guidelines.

Only way to ensure proper ratios is to be on site counting the amount of material during the batching process at the rig and then being able to know the water ratio at the nozzle, this is where the gunite mix can be altered outside of parameters.

Gunite typically will produce more rebound than Shotcrete and that needs to be discussed in regards to what will be done with this left over product.

PLASTER

all I can advise is to be onsite during this process to witness the mixture and ask questions of the onsite crew of their process.

For me its years of exposure to the application/mixing process to be able to see how a proper mix is made and applied. Having seen a specific company/crew work many times previously, gives me the confidence that it will be successful.

EQUIPMENT PAD SIZE

4’ X 10’ is the smallest size the plumber I have experience with will request depending on amount of equipment needed.

DECKING

the #3 rebar must be on chairs and not lifted by hand as the cement is being poured around it or the rebar left to lay on the ground.

Everything can be written on paper of what is required, but without proper supervision, the chances become less. This is where you need to stress your concerns and what you expect of the finished product for each phase.

Last edited:

There is a lot of activities in process on day of gunite and on day of plaster. Don’t expect that you can oversee it all by yourself. Identify the supervisor for each process and ask how the crew will provide a quality process.

This is the list of things do before plaster day - save it for when that happens in the future.

Day of Plaster

This is the list of things do before plaster day - save it for when that happens in the future.

Day of Plaster

- Clean up around the pool area the day before - brush any dirt/mud or debris that could be tracked into the pool during or after plaster

- Verify that the bags of plaster are the proper type and color you selected on morning of plaster.

- Take a sample of the mixture when they are applying it to the pool by pouring some in a small clear plastic cup (good for reference later)

- Do they have all the proper return nozzles and drain covers (type and color) to place after plaster installed

- Have you tested your fill water? Are you filling with softened water or regular tap water or well water?

- Have your hose ready (and clean) as it will be laying in the pool.

- Tie a sock or cloth around the nozzle so it does not sit on the plaster or place a pool noodle over the hose end. See more below.

- Put the end of the hose at the lowest part of the pool to avoid channeling in the new plaster. Also, consider tying a plastic jug to the nozzle such that it will float up as the water rises. Or another method is to take two pool noodles and threaded the hoses through the middle of the noodles which will keep the hose suspended on the water surface and away from the pool walls.

- Ensure you take note (or a picture) of your water meter reading before you start to fill

- Be prepared to take note of your water meter as the pool reaches certain levels, i.e bottom of bottom step, top of bottom step, etc. (it helps in the future to know volume of your pool at certain levels - should you ever have to drain portion of it)

- Plan to set an alarm every 4 hours (or so) to ensure hose is still in pool, no debris blew into pool, etc.

- Do NOT stop the flow of water once the pool starts filling as doing so could cause a ring on the new plaster.

- Take a picture of any chemicals they bring on site that they plan to dump in when they start to add water to pool

- Continue to fill pool to center of water tile or center of skimmer. Take picture of water meter at end of fill

- Get clear instructions from PB as what to do the day the pool is full - how often to brush, will the pump be turned on, etc.

- Define with PB when he will be back out to set up water chemistry.

Thanks a lotWith expansive clay soil, request a steel engineering report that advises what is required for your specific pool.

GUNITE

4:1 mix is minimum for Gunite.

Gunite is mixed on site, unlike Shotcrete that is batched by a computer at a concrete yard within very strict guidelines.

Only was to ensure proper ratios is to be on site counting the amount of material during the batching process at the rig and then being able to know the water ratio at the nozzle, this is where the gunite mix can be altered outside of parameters.

Gunite typically will produce more rebound than Shotcrete and that needs to be discussed in regards to what will be done with this left over product.

PLASTER

all I can advise is to be onsite during this process to witness the mixture and ask questions of the onsite crew of their process.

For me its years of exposure to the application/mixing process to be able to see how a proper mix is made and applied. Having seen a specific company/crew work many times previously, gives me the confidence that it will be successful.

EQUIPMENT PAD SIZE

4’ X 10’ is the smallest size the plumber I have experience with will request depending on amount of equipment needed.

DECKING

the #3 rebar must be on chairs and not lifted by hand as the cement is being poured around it or the rebar left to lay on the ground.

Everything can be written on paper of what is required, but without proper supervision, the chances become less. This is where you need to stress your concerns and what you expect of the finished product for each phase.

thank you very much for your great inputThere is a lot of activities in process on day of gunite and on day of plaster. Don’t expect that you can oversee it all by yourself. Identify the supervisor for each process and ask how the crew will provide a quality process.

This is the list of things do before plaster day - save it for when that happens in the future.

Day of Plaster

- Clean up around the pool area the day before - brush any dirt/mud or debris that could be tracked into the pool during or after plaster

- Verify that the bags of plaster are the proper type and color you selected on morning of plaster.

- Take a sample of the mixture when they are applying it to the pool by pouring some in a small clear plastic cup (good for reference later)

- Do they have all the proper return nozzles and drain covers (type and color) to place after plaster installed

- Have you tested your fill water? Are you filling with softened water or regular tap water or well water?

- Have your hose ready (and clean) as it will be laying in the pool.

- Tie a sock or cloth around the nozzle so it does not sit on the plaster or place a pool noodle over the hose end. See more below.

- Put the end of the hose at the lowest part of the pool to avoid channeling in the new plaster. Also, consider tying a plastic jug to the nozzle such that it will float up as the water rises. Or another method is to take two pool noodles and threaded the hoses through the middle of the noodles which will keep the hose suspended on the water surface and away from the pool walls.

- Ensure you take note (or a picture) of your water meter reading before you start to fill

- Be prepared to take note of your water meter as the pool reaches certain levels, i.e bottom of bottom step, top of bottom step, etc. (it helps in the future to know volume of your pool at certain levels - should you ever have to drain portion of it)

- Plan to set an alarm every 4 hours (or so) to ensure hose is still in pool, no debris blew into pool, etc.

- Do NOT stop the flow of water once the pool starts filling as doing so could cause a ring on the new plaster.

- Take a picture of any chemicals they bring on site that they plan to dump in when they start to add water to pool

- Continue to fill pool to center of water tile or center of skimmer. Take picture of water meter at end of fill

- Get clear instructions from PB as what to do the day the pool is full - how often to brush, will the pump be turned on, etc.

- Define with PB when he will be back out to set up water chemistry.