Hi all. I'm looking for some opinions from plumbing pros on some upcoming rework I am doing to my pool equipment plumbing (work will be done by pool plumber, not myself). We built our pool and finished up late last year. There is a filter pump dedicated to the pool circulation and the bubblers feature. There is a dedicated pump that drives the waterfall. Unfortunately, forethought was not done to ensure the supply to the waterfall was adequate or dedicated. I am looking for any advice or gotchas people may see with some proposed changes I am having done. (See several diagrams below).

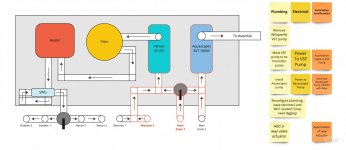

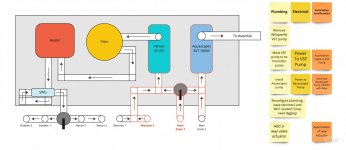

You can see the ORIGINAL plumbing here.

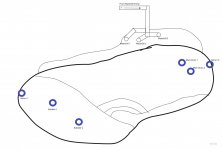

And a horrible sketch of my pool and the waterfall return as well as all the returns/skimmers/drains. This is all the supply available for circulation and water features.

The waterfall builder had requested a flow rate of 210 GPM (12,600 GPH) based on total head. My pool builder chose a Pentair XF VSF. However, even at max RPMs and very little head, this pump isn't rated for that flow...and is NOISY AS heck.

When we turned on the system, we had two problems: 1) inadequate flow to waterfalls and 2) lack luster flow to the bubblers

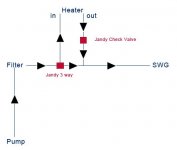

The first attempt was hoping that maybe this was a supply issue, as the line to the waterfall(s) was a 3" line and was being staved by only have 2" of intake. We (temporarily) directed one skimmer to go with one main drain as supply for the waterfall. See below:

Flow did improve to the waterfall, but it still is not quite where we need it. I could find no pentair pool pump that would give the flow needed at less-than-a-jet-engine volume levels and my waterfall builder recommended using a waterfall/pond pump. I now have an Aquascapes EXT 18000 (external) pump I am planning to install. This pump is a single speed low RPM (~2500 RPM) with a rated flow of 18,000 GPH (300 GPM). With the total head (it's a fairly long run and several fitting, but not a lot of head height) we believe this pump has what we need to drive the waterfall. I am going to move the Pentair XF VSF pump to the filter side and hope this will provide enough wow factor to the bubblers when needed and sell the Whisperflo XF VSF.

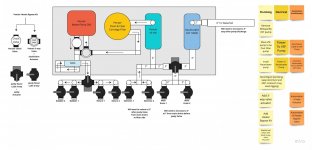

Because we have limited choice of supply lines for the waterfall pump, this is my proposed plan. I don't like the idea of a skimmer being used for supply as nothing in that filter would get sanitized/filtered while the waterfall is on. Instead we plan to send both main drains to the waterfall when it is on, and one main drain to the filter side when the waterfall is off. One main drain will always be supplying the waterfall so there would never could be a negative supply if the waterfall pump was on. I plan to actuate the valve between filter and waterfall side with the activation of the waterfall feature. Thoughts? Are there any pitfalls with this I am not seeing. I haven't heard back from the plumbing on this proposed design yet but it is close to what we have discussed and we planned to implement this month right before I open the pool for the season.

Proposed plumbing changes (in red):

You can see the ORIGINAL plumbing here.

And a horrible sketch of my pool and the waterfall return as well as all the returns/skimmers/drains. This is all the supply available for circulation and water features.

The waterfall builder had requested a flow rate of 210 GPM (12,600 GPH) based on total head. My pool builder chose a Pentair XF VSF. However, even at max RPMs and very little head, this pump isn't rated for that flow...and is NOISY AS heck.

When we turned on the system, we had two problems: 1) inadequate flow to waterfalls and 2) lack luster flow to the bubblers

The first attempt was hoping that maybe this was a supply issue, as the line to the waterfall(s) was a 3" line and was being staved by only have 2" of intake. We (temporarily) directed one skimmer to go with one main drain as supply for the waterfall. See below:

Flow did improve to the waterfall, but it still is not quite where we need it. I could find no pentair pool pump that would give the flow needed at less-than-a-jet-engine volume levels and my waterfall builder recommended using a waterfall/pond pump. I now have an Aquascapes EXT 18000 (external) pump I am planning to install. This pump is a single speed low RPM (~2500 RPM) with a rated flow of 18,000 GPH (300 GPM). With the total head (it's a fairly long run and several fitting, but not a lot of head height) we believe this pump has what we need to drive the waterfall. I am going to move the Pentair XF VSF pump to the filter side and hope this will provide enough wow factor to the bubblers when needed and sell the Whisperflo XF VSF.

Because we have limited choice of supply lines for the waterfall pump, this is my proposed plan. I don't like the idea of a skimmer being used for supply as nothing in that filter would get sanitized/filtered while the waterfall is on. Instead we plan to send both main drains to the waterfall when it is on, and one main drain to the filter side when the waterfall is off. One main drain will always be supplying the waterfall so there would never could be a negative supply if the waterfall pump was on. I plan to actuate the valve between filter and waterfall side with the activation of the waterfall feature. Thoughts? Are there any pitfalls with this I am not seeing. I haven't heard back from the plumbing on this proposed design yet but it is close to what we have discussed and we planned to implement this month right before I open the pool for the season.

Proposed plumbing changes (in red):