A little while ago, decided to convert to a SWG.

Settled on Hayward because I want to add a RS-485 interface to give me remote control capabilities, and Hayward SWG's seem to be good, I see recommendations here for them.

Planning to install over the long weekend.

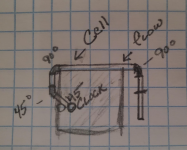

The red rectangle in the picture is the space I have for a SWG. Its less than 12" long between the elbows, so not enough.

I plan to cut around 7" of pipe in the middle, and add a couple elbows into a home made vertical type U shaped adapter.

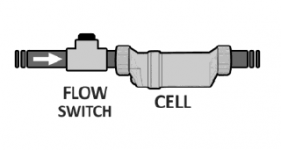

Hayward wants 12" of straight pipe before the flow sensor, so planning to have elbow to 12" of straight pipe to flow sensor to two elbows (making the U) to SWG to elbow back into existing pipe.

I'll post a pic after I put something together so its clearer what I'm doing.

The gas line to the heater is under the pipe where I am installing, so I can't go straight down. I can go up, but it would be exposed to a lot of sun if I did that.

I think it would fit going down, at an angle toward the heater.

Could also install horizontally, then it would be over my pump.

Wondering what the experts here think about how I should install?

The control panel is going on the wall between the heater and filter, I rearranged the boxes yesterday to make the space, and even have mounting screws in the wall.

I also am documenting my install here

Thanks

Randy

Settled on Hayward because I want to add a RS-485 interface to give me remote control capabilities, and Hayward SWG's seem to be good, I see recommendations here for them.

Planning to install over the long weekend.

The red rectangle in the picture is the space I have for a SWG. Its less than 12" long between the elbows, so not enough.

I plan to cut around 7" of pipe in the middle, and add a couple elbows into a home made vertical type U shaped adapter.

Hayward wants 12" of straight pipe before the flow sensor, so planning to have elbow to 12" of straight pipe to flow sensor to two elbows (making the U) to SWG to elbow back into existing pipe.

I'll post a pic after I put something together so its clearer what I'm doing.

The gas line to the heater is under the pipe where I am installing, so I can't go straight down. I can go up, but it would be exposed to a lot of sun if I did that.

I think it would fit going down, at an angle toward the heater.

Could also install horizontally, then it would be over my pump.

Wondering what the experts here think about how I should install?

The control panel is going on the wall between the heater and filter, I rearranged the boxes yesterday to make the space, and even have mounting screws in the wall.

I also am documenting my install here

Thanks

Randy