I did but I'm not sure what happened to him...here one day, gone the next.Do you also have a Tweety Bird?

First pool Tampa area - Plumbing question

- Thread starter TampaKathy

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

While following along on someone else's post about their SWG not being plumbed correctly, I realized that mine was not either, grrr. Before I contact my PB and get the BS, "ThAt'S HoW We AlwAyS Do It" nonsense, I'd like to see if the experts on here think that I don't have a problem. I apologize if this is a stupid question but I'm not a plumber, lol.

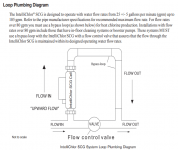

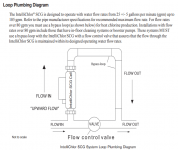

I have an IFCS. Per the Pentair IC60 installation instructions, when you have an IFCS, the SWG system must use a bypass loop (see below). When the SWG was installed of course there was no bypass, however, after the fact I had a heat pump/chiller installed by another company and the heat pump/chiller has a bypass. My question: Do you think the bypass in front of the heater accomplishes what is needed for the SWG OR should I still contact the PB and tell them I need a bypass in front of the SWG?

I have an IFCS. Per the Pentair IC60 installation instructions, when you have an IFCS, the SWG system must use a bypass loop (see below). When the SWG was installed of course there was no bypass, however, after the fact I had a heat pump/chiller installed by another company and the heat pump/chiller has a bypass. My question: Do you think the bypass in front of the heater accomplishes what is needed for the SWG OR should I still contact the PB and tell them I need a bypass in front of the SWG?

Attachments

Turbo1Ton

Gold Supporter

- Dec 26, 2019

- 1,839

- Pool Size

- 14500

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-40

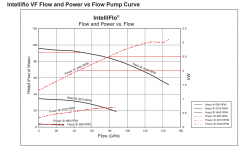

I have an IFCS and do not have the bypass. What flow rate does your pump tell you its running when your IFCS is on? Mine runs @ 2700rpm and shows about 53GPM.

The stated acceptable flow rate is 105GPM. Not sure why they want the bypass for 80 GPM. Apparently over 80 GPM the cell may not produce chlorine properly?

--Jeff

The stated acceptable flow rate is 105GPM. Not sure why they want the bypass for 80 GPM. Apparently over 80 GPM the cell may not produce chlorine properly?

--Jeff

- Nov 12, 2017

- 11,903

- Pool Size

- 12300

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-40

Perhaps @JamesW could weigh in. Jeff brings up a good point. Pentair: is it 80, or is it 105? According to the instructions, you'll only need a bypass if your return to the pool (or your IFCS) is over 80. Either way, no, the heater bypass won't help with that, it's only "protecting" the heater the way it's plumbed now.

I don't have IFCS, rather solar, but I get about 40GPM @ 2400RPM, which is similar to what Jeff is seeing. All pools are different, so it's not a direct correlation between RPM and flow, but to get up to 80 GPM your pump would have to really be pumpin'! What is the RPM when the IFCS is engaged?

I don't have IFCS, rather solar, but I get about 40GPM @ 2400RPM, which is similar to what Jeff is seeing. All pools are different, so it's not a direct correlation between RPM and flow, but to get up to 80 GPM your pump would have to really be pumpin'! What is the RPM when the IFCS is engaged?

- Nov 12, 2017

- 11,903

- Pool Size

- 12300

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-40

@JamesW, can a Pentair VS pump do that? I'm really asking for myself, because I don't think mine can. Kathy's signature states VS pumps, not VSF, unless you're remembering something else about her setup. I only know about my 40GPM because I have a FloVis...

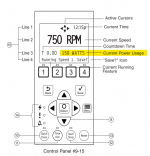

The new pumps are VSF and they can show GPM, Watts and PSI.@JamesW, can a Pentair VS pump do that?

Put your system in Service mode and use your pump keypad to check your numbers.

- Nov 12, 2017

- 11,903

- Pool Size

- 12300

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-40

Ah, thanks. Mine is a VST, and it's manual doesn't have anything in it about GPM, Watts or PSI... If Kathy can get to her GPM, then she should be able to answer her own question about the need for a bypass.

Turbo1Ton

Gold Supporter

- Dec 26, 2019

- 1,839

- Pool Size

- 14500

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-40

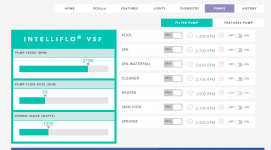

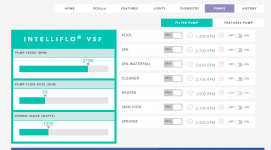

She also has the Intellicenter. She can easily find it in there as long as the pump is configured as a VSF. If not she'll want to check at the pump like James showed above.

Screenshot from the pumps tab on the web app @ www.intellicenter2.com

--Jeff

Screenshot from the pumps tab on the web app @ www.intellicenter2.com

--Jeff

- Nov 12, 2017

- 11,903

- Pool Size

- 12300

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-40

Yah, I misspoke. Watts show up in my EasyTouch, too. I've only once fooled with my pump display, when I had my EasyTouch board mailed out for an upgrade, so I don't know much about it, to be honest. The display doesn't even work anymore. I think I have the known problem with that (something about the connections underneath it). ET does all the programming. My stuff is not that old, but from the screenshots here, especially the IntelliCenter, I'm feelin' all stone-agie.

Turbo1Ton

Gold Supporter

- Dec 26, 2019

- 1,839

- Pool Size

- 14500

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-40

That is correct. I don't have anywhere to see pressure from Intellicenter.I don't think that the IntelliCenter shows the system pressure?

--Jeff

I was running my IFCS at like 3000 rpm which was over 80 gpm. If I reduce the rpm to 2700, the gpm is between 60 and 70 but goes up to 80 when switching zones. My filter pressure is at 18psi with IFCS running. Fixed my signature to say VSF pump

- Nov 12, 2017

- 11,903

- Pool Size

- 12300

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-40

It's probably overkill, but if you're hitting 80 then you should follow Pentair's installation instructions. Otherwise, you might compromise the SWG, but more importantly its warranty. Things of this nature tend to get forgotten over time, and when your IFCS needs a bit more oomph someday, and you turn the RPMs back up, are you going to remember you can't do that (if you don't alter the plumbing). Your plumbing should accommodate all likely use cases, including future ones, and it sounds to me like it's not quite up to that.

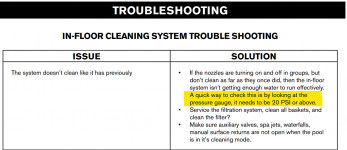

The PV3 manual shows a pressure gauge on the water valve but the PB didn't install one. There is a pressure gauge on the filter. Is it redundant to have it on the water valve or should I have it in both places?

Did the gauge ever get installed?I was running my IFCS at like 3000 rpm which was over 80 gpm.

I doubt that you need 80 GPM.

I would dial it down as much as possible as long as it still works ok.

The manual says 20 psi, but that seems high to me.

I suspect that it would work at lower pressure.

I will definitely NOT remember that, lol!It's probably overkill, but if you're hitting 80 then you should follow Pentair's installation instructions. Otherwise, you might compromise the SWG, but more importantly its warranty. Things of this nature tend to get forgotten over time, and when your IFCS needs a bit more oomph someday, and you turn the RPMs back up, are you going to remember you can't do that (if you don't alter the plumbing). Your plumbing should accommodate all likely use cases, including future ones, and it sounds to me like it's not quite up to that.

The gauge was installed...it's only at 10-12 psi when at 2700rpm.Did the gauge ever get installed?

I doubt that you need 80 GPM.

I would dial it down as much as possible as long as it still works ok.

The manual says 20 psi, but that seems high to me.

I suspect that it would work at lower pressure.

View attachment 434680

Is the performance acceptable at that pressure?The gauge was installed...it's only at 10-12 psi when at 2700rpm.

Thread Status

Hello , This thread has been inactive for over 60 days. New postings here are unlikely to be seen or responded to by other members. For better visibility, consider Starting A New Thread.