I have a new pool (finishing up plumbing) and have been meticulous about reading codes/recommendations/best practices/etc. on GPM and plumbing requirements. Now about to finish my plumbing (equipment side) and having trouble finding right fittings that makes me wonder about everything I have read so far - it seems really difficult to build truly 2.5" plumbing. Any advice will be appreciated:

About the pool:

I have relatively small 11,000 pool/spa combo that requires 20 to 90GPM (I have 9 waterway jets, each 10GPM) and extremely short/direct feet of head. ( will have a separate post why I need up to 90GPM and how plumbing is done - I did lots of research and it will be too much to go in this post) My plumbing is set up with 2.5" pipes.

About the standards:

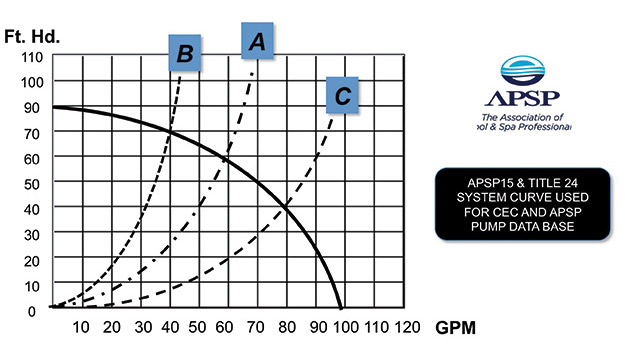

Based on what I have read, 2" piping only supports around 80GPM (or 63GPM on suction and 84GPM on return side). Numbers for 1.5" are around 35GPM suction and 50GPM return. So, if the max flow requirements are above 70GPM, one should use 2.5".

Issues to achieve true 2.5" plumbing:

Is it really possible to build pool with true 2.5" plumbing?

If pool has 70GPM+ requirement (max), ideally, one should use 2.5" plumbing. I can imagine many 30-40k gallon pools with extra features fall in this category. I see only three potential scenarios and any advice will be appreciated:

About the pool:

I have relatively small 11,000 pool/spa combo that requires 20 to 90GPM (I have 9 waterway jets, each 10GPM) and extremely short/direct feet of head. ( will have a separate post why I need up to 90GPM and how plumbing is done - I did lots of research and it will be too much to go in this post) My plumbing is set up with 2.5" pipes.

About the standards:

Based on what I have read, 2" piping only supports around 80GPM (or 63GPM on suction and 84GPM on return side). Numbers for 1.5" are around 35GPM suction and 50GPM return. So, if the max flow requirements are above 70GPM, one should use 2.5".

Issues to achieve true 2.5" plumbing:

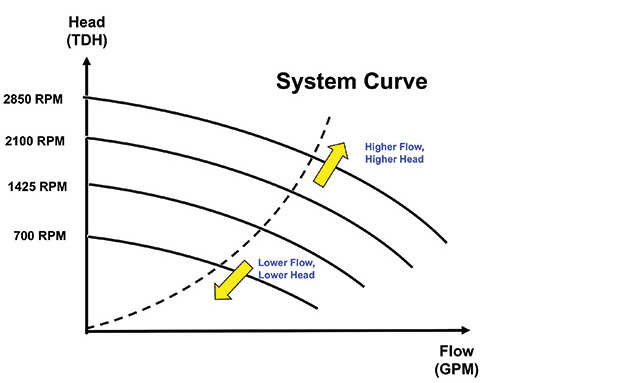

- Pump: 1.5HP Pentair VS Superflow seems to perfectly fit the bill (20GPM most of the time with occasional 90GPM). Yet, the inlet and outlet on the pump are 1.5". I had previously posted about this but, frankly, responses were not quite clear. So, unless there is a good explanation, I am being forced to put 1.5" 'bottleneck' in my 2.5" piping system and cannot find a reasonable workaround unless I go with 3hp pump (which I definitely don't need).

- Salt chlorine generators - all of them, (up to 40,000 gallon versions) have up to 2" plumbing (with further restrictions inside the box). I couldn't find residential chlorine generator with 2.5" piping.

- Same issue with inline chlorine feeder (and they are very restricted inside, way beyond 2"). Even off-line chlorine feeders come with clamp that work on pipes up to 2"

Is it really possible to build pool with true 2.5" plumbing?

If pool has 70GPM+ requirement (max), ideally, one should use 2.5" plumbing. I can imagine many 30-40k gallon pools with extra features fall in this category. I see only three potential scenarios and any advice will be appreciated:

- the 64GPM for 2" is arbitrary and there is lots of "cushion" for higher flows. People just stick with 2" plumbing; or they just put bunch of 2inch "bottlenecks" in their 2.5inch systems.

- There are 2.5" fittings for salt chlorine generators and chlorine feeders through specialty stores that I cannot find (but manufacturers such as hayward would list them, right?)

- People extensively use pressure-sensitive bypass valves that enable to direct subset of flow through restrictive salt chlorinators (that still doesn't explain what they do with pumps that are rated at 100GPM but have 1.5" inlet and outlet). Also, this set up would complicate the system and increase the overall feet of head - just doesn't seem ideal.

Last edited: