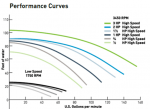

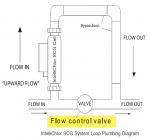

What is this flow control valve and where can I get one? Since I have an in-floor system I need to ensure that the Intellichlor IC40 plumbed like this to keep flow rates below 80 gpm (my warranty depends on it):

It also seems like some calculations would be in order here. Like how tall should I make my loop? And how does that relate to the flow control valve?

It also seems like some calculations would be in order here. Like how tall should I make my loop? And how does that relate to the flow control valve?