Thoughts on my pool equipment install

- Thread starter rocketx2

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Jun 24, 2021

- 7,512

- Pool Size

- 30000

- Surface

- Vinyl

- Chlorine

- Salt Water Generator

- SWG Type

- CircuPool RJ-60

Hey, welcome to TFP!!

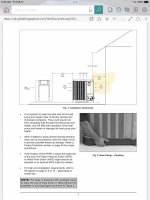

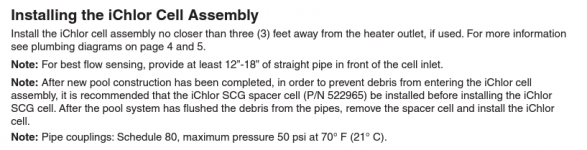

From the manual for the ichlor:

1) you want 12-18 inches of straight pipe in front of cell

2) 3' away from heater

3) use the spacer cell while the pool system is flushed.

The ball valves that they have installed will, at some point, become unusable. Those valves become hard to turn, until they don't turn. Likely better to put in never lube valves. They can be rebuilt easily.

The heater bypass can be done with one neverlube and a check valve. The way they have done it, while functional, requires thinking about all the valve positions...with potential for error.

From the manual for the ichlor:

1) you want 12-18 inches of straight pipe in front of cell

2) 3' away from heater

3) use the spacer cell while the pool system is flushed.

The ball valves that they have installed will, at some point, become unusable. Those valves become hard to turn, until they don't turn. Likely better to put in never lube valves. They can be rebuilt easily.

The heater bypass can be done with one neverlube and a check valve. The way they have done it, while functional, requires thinking about all the valve positions...with potential for error.

Welcome! I would 100% insist that they remove the junk ball valves and install proper Jandy-style valves, and I couldn't agree more on redesigning the bypass.

Hey Rocket and Welcome !!!!

They did you no favors with a small filter. All filters work fine, but bigger ones need to be cleaned less often because they hold more. Say it needs to be cleaned 4X a year over 20 years and the big one only needs one cleaning per season, that's 60 extra cleanings.

I like playing with the hose and cleaning mine. But I like doing it because I want to and not because I need to.

They did you no favors with a small filter. All filters work fine, but bigger ones need to be cleaned less often because they hold more. Say it needs to be cleaned 4X a year over 20 years and the big one only needs one cleaning per season, that's 60 extra cleanings.

I like playing with the hose and cleaning mine. But I like doing it because I want to and not because I need to.

Thank you for your reply. I'm a real neophyte at this, that's a heat pump, not a heater does that matter?Hey, welcome to TFP!!

From the manual for the ichlor:

1) you want 12-18 inches of straight pipe in front of cell

2) 3' away from heater

3) use the spacer cell while the pool system is flushed.

View attachment 473651

The ball valves that they have installed will, at some point, become unusable. Those valves become hard to turn, until they don't turn. Likely better to put in never lube valves. They can be rebuilt easily.

The heater bypass can be done with one neverlube and a check valve. The way they have done it, while functional, requires thinking about all the valve positions...with potential for error.

I'm sure your observations are correct, let me make sure I understand.

First, they didn't install the iclore with enough pipe in front, correct? Based on the picture, how much more do I need? Second, they didn't install the iclore spacer cell, correct?

I'm sorry to have such basic questions but I'm really at Square One. Thanks again for your Insight.

(I also have questions about automation but that square two)

- Jun 24, 2021

- 7,512

- Pool Size

- 30000

- Surface

- Vinyl

- Chlorine

- Salt Water Generator

- SWG Type

- CircuPool RJ-60

The heat pump heats the water. It is a water heater. A water heater is a heater. Heaters can be propane, natural gas, heat pump, solar...they are all heaters.Thank you for your reply. I'm a real neophyte at this, that's a heat pump, not a heater does that matter?

Yes, and yes. There should be 12-18" of straight pipe before the cell. When they start up the pool the spacer should be in place until you are certain particulates are out of the water. By putting the spacer in place (removing the cell), then the cell doesn't get clogged with a bunch of builder remainder bits. Your filter will catch them. The spacer looks like this:I'm sure your observations are correct, let me make sure I understand.

First, they didn't install the iclore with enough pipe in front, correct? Based on the picture, how much more do I need? Second, they didn't install the iclore spacer cell, correct?

While it might cost a little to replace the ball valves with Jandy/Never-Lube, in my experience, I would do it now. Will save a bunch later.

- Dec 13, 2020

- 755

- Pool Size

- 19600

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Jandy Aquapure 1400

Hi. Consider adding all your equipment in your signature. That way people here can help more easily.

Your pump looks like a Pentair Superflow. The manual says "However, we also recommend that a valve, elbow or tee installed in the suction line should be no closer to the front of the pump than 5 times the suction line diameter." So if your pipe is 2", another guess, there should be a 10" straight section between the valve and it. Looks like you don't even have 2. That section lets the flow smooth out before the pump chamber, which makes life easier and more efficient for the pump. Even if I guessed wrong on the pump model, most others will be the same.

Your pump looks like a Pentair Superflow. The manual says "However, we also recommend that a valve, elbow or tee installed in the suction line should be no closer to the front of the pump than 5 times the suction line diameter." So if your pipe is 2", another guess, there should be a 10" straight section between the valve and it. Looks like you don't even have 2. That section lets the flow smooth out before the pump chamber, which makes life easier and more efficient for the pump. Even if I guessed wrong on the pump model, most others will be the same.

First, I added my pool to my signature, that's a great idea thanks! I'm not sure where the signature shows up but if you think I need to improve it please let me know and I will.Hi. Consider adding all your equipment in your signature. That way people here can help more easily.

Your pump looks like a Pentair Superflow. The manual says "However, we also recommend that a valve, elbow or tee installed in the suction line should be no closer to the front of the pump than 5 times the suction line diameter." So if your pipe is 2", another guess, there should be a 10" straight section between the valve and it. Looks like you don't even have 2. That section lets the flow smooth out before the pump chamber, which makes life easier and more efficient for the pump. Even if I guessed wrong on the pump model, most others will be the same.

You're correct, it's a 1.5 HP super flow. My first concern is I had no conversations about what equipment would be installed. I want to do automation don't you need an intelliflow for automation?

Under your posts. Turn your phone sideways and it pops up in landscape mode. Ya did good.I'm not sure where the signature shows up

- Jun 24, 2021

- 7,512

- Pool Size

- 30000

- Surface

- Vinyl

- Chlorine

- Salt Water Generator

- SWG Type

- CircuPool RJ-60

That's a pretty simple setup. What do you want to automate? What do you want from the automation?I want to do automation don't you need an intelliflow for automation?

Thanks for all the great insights.

Based on your input, I now understand I need at least 10 in of pipe going into the pump so this morning I went outside and put a tape measure on it. I'm so new at this I don't know what counts towards the 10 inches. Thoughts? Thank You!

You've also taught me the iclor has to be 3 feet from the heater. So I'm posting that picture as well. Is this right?

Based on your input, I now understand I need at least 10 in of pipe going into the pump so this morning I went outside and put a tape measure on it. I'm so new at this I don't know what counts towards the 10 inches. Thoughts? Thank You!

You've also taught me the iclor has to be 3 feet from the heater. So I'm posting that picture as well. Is this right?

- Jun 24, 2021

- 7,512

- Pool Size

- 30000

- Surface

- Vinyl

- Chlorine

- Salt Water Generator

- SWG Type

- CircuPool RJ-60

It is simple... maybe too simple. I wasn't consulted.That's a pretty simple setup. What do you want to automate? What do you want from the automation?

The guy who's building the pool isn't the guy who's installing the equipment. The equipment guy showed up looked at the pad and left. A week later two more guys showed up in a pickup with a bunch of equipment, and you see what I have.

I don't consider myself to be a dumb guy but I've been all over the internet looking at Pentair info and this is really hard to navigate. I've yet to find a place on the internet that lays out how all the different Pentair systems work together or not.

Based on what I've gleaned from Google and YouTube... I want to automate the pump, automate the two bubblers and the lights from my phone (Pentair Home?) Pretty simple. I thought that meant I needed an intelliflow pump and an intelliscenter automation unit. But like I said, I've had no conversations with the equipment guy.

I'd really appreciate your insights. Thank you!

- Jun 24, 2021

- 7,512

- Pool Size

- 30000

- Surface

- Vinyl

- Chlorine

- Salt Water Generator

- SWG Type

- CircuPool RJ-60

Let's see what @ajw22 @JamesW and @Jimrahbe have to say. They are some of the automation folks...Based on what I've gleaned from Google and YouTube... I want to automate the pump, automate the two bubblers and the lights from my phone (Pentair Home?) Pretty simple. I thought that meant I needed an intelliflow pump and an intelliscenter automation unit. But like I said, I've had no conversations with the equipment guy.

I'd really appreciate your insights. Thank you!

- Jul 21, 2013

- 53,006

- Pool Size

- 35000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

The length of your pump input is fine.Thanks for all the great insights.

Based on your input, I now understand I need at least 10 in of pipe going into the pump so this morning I went outside and put a tape measure on it. I'm so new at this I don't know what counts towards the 10 inches. Thoughts? Thank You!

You've also taught me the iclor has to be 3 feet from the heater. So I'm posting that picture as well. Is this right?

View attachment 473720

The position of your iChor is ok. Not optimum but ok.

What has not been mentioned is your Heat Pump is right next to your AC condenser. When both units are running their air flow and heat output will interfere with each other and affect their operation. I think if you check the installation document for each you will find minimum separations between units which it does not look like you have.

The major problems I see are your ball valves that should be diverters and your small cartridge filter.

To automate valves they need to be diverter valves that actuators can be placed on, not ball valves.

What model number is your pump? Post a clear pic of the labels on the front of the pump.

There are simpler and lower cost automation systems that automate a VS pump but when you throw in wanting to automate valves for water features you jump to the high end old EasyTouch system or newer IntelliCenter.

Pentair Automation Systems - Further Reading

First priority to me would be getting rid of all the ball valves on your system.

Last edited:

- Jul 21, 2013

- 53,006

- Pool Size

- 35000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

Thank you so much! I'll read through that automation documentation this weekend.The length of your pump input is fine.

The position of your iChor is ok. Not optimum but ok.

What has not been mentioned is your Heat Pump is right next to your AC condenser. When both units are running their air flow and heat output will interfere with each other and affect their operation. I think if you check the installation document for each you will find minimum separations between units which it does not look like you have.

The major problems I see are your ball valves that should be diverters and your small cartridge filter.

To automate valves they need to be diverter valves that actuators can be placed on, not ball valves.

What model number is your pump? Post a clear pic of the labels on the front of the pump.

There are simpler and lower cost automation systems that automate a VS pump but when you throw in wanting to automate valves for water features you jump to the high end old EasyTouch system or newer IntelliCenter.

Pentair Automation Systems - Further Reading

www.troublefreepool.com

First priority to me would be getting rid of all the ball valves on your system.

Yes, the Reem heat pump is next to my condenser. I'm worried about that too.

I wish I had discovered TFP sooner.

It's a 1.5 HP Superflow. I would have paid for an intelliflow upgrade. Can this pump be automated with Pentair's automation packages?

- Jul 21, 2013

- 53,006

- Pool Size

- 35000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

You have a Superflo VST.

You showed me the label on the side. Now show me the labels on the front around the input pipe.

That pump can be controlled by most of the Pentair automation systems. Check on specific compatibility of the ones you choose.

You showed me the label on the side. Now show me the labels on the front around the input pipe.

That pump can be controlled by most of the Pentair automation systems. Check on specific compatibility of the ones you choose.

- Jul 21, 2013

- 53,006

- Pool Size

- 35000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

Thread Status

Hello , This thread has been inactive for over 60 days. New postings here are unlikely to be seen or responded to by other members. For better visibility, consider Starting A New Thread.