Let’s talk about that spa spillover…

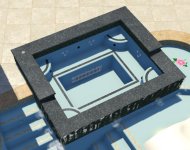

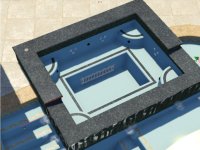

As designed the spillover is half the surface area of the spa perimeter. The longer the spillover is the more water flow will be needed in POOL mode for a smooth spillover.

You will find that continuous running a spillover, especially with a lot of surface area, creates aeration which causes pH to rise rapidly which then requires frequent acid additions to lower pH. For that reason we recommend not continually running the spillover and scheduling SPILLOVER mode on your automation to refresh your spa a few times a day for 15 minutes.

Also as designed the spillover is alongside the steps which means water will splash on people entering and exiting the pool. And that side can be used by people as a handrail to steady themselves. I am not sure having water spillover the step areas will be enjoyable or even safe at times.

Also the entire edge of the spillover must be level for the water to evenly flow. The longer the spillover is the more you create a challenge for the mason to get that stone perfect for the water flow. Those craftsmen are hard to find.

These are all practical reasons why I would reduce the spillover area to one length of the spa and even less then the full length. What looks cool on design drawings is often not the best to build and live with.