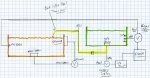

Have 16k gallon pool with automatic cover as well as an 800 gallon elevated spa. Because of the automatic pool cover, both the pool and spa have separate sand filters and variable speed pumps. As such, I have 2 separate chemistries to maintain.

I also just installed a heat pump for the pool. Our spa has a gas heater which is currently broke. I'm guessing it will not be worth the money to fix.

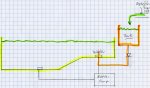

I'm interested in finding a way to combine both the pool and spa circulations with one pump and one filter. The spa as a main drain, but no skimmer.

Goals:

1) Combine pool and spa circulation with one sand filter and one pump.

2) When wanted, be able to heat only the pool with the heat pump.

3) When wanted, be able to heat only the spa with the heat pump.

Is the above possible? I'm thinking the biggest hurdle will be creating a "virtual spillover" for the spa to maintain correct water level in both the pool and spa. However, I have no experience and can find very little info on this topic.

Any help would be greatly appreciated. Thanks in advance. Chad

I also just installed a heat pump for the pool. Our spa has a gas heater which is currently broke. I'm guessing it will not be worth the money to fix.

I'm interested in finding a way to combine both the pool and spa circulations with one pump and one filter. The spa as a main drain, but no skimmer.

Goals:

1) Combine pool and spa circulation with one sand filter and one pump.

2) When wanted, be able to heat only the pool with the heat pump.

3) When wanted, be able to heat only the spa with the heat pump.

Is the above possible? I'm thinking the biggest hurdle will be creating a "virtual spillover" for the spa to maintain correct water level in both the pool and spa. However, I have no experience and can find very little info on this topic.

Any help would be greatly appreciated. Thanks in advance. Chad