- Apr 2, 2020

- 12

- Pool Size

- 15000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Turbo Cell (T-CELL-5)

Hello All,

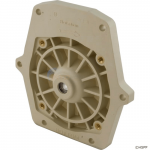

My pump had seemingly been running fine for the past ~8 years but I turned it off to switch over for a backwash and when I switched the pump back on it showed an over current error that won't clear. Read through a few threads and found my impeller wouldn't budge. I took the pump out and found that the impeller was crooked against the seal plate. I was able to force it off and you can see in the picture below the amount of rubbing that was occurring. I am uncertain of how much more of the motor to take apart and work on due to the age.

Hoping an expert can guide as to whether this looks like it may be something easy to fix on the inside or to just move on to a new pump. It does seem that the motor is about 1/3 the cost of getting a new pump outright so perhaps it is worth replacing just the motor.

Appreciate your help!

Brian

My pump had seemingly been running fine for the past ~8 years but I turned it off to switch over for a backwash and when I switched the pump back on it showed an over current error that won't clear. Read through a few threads and found my impeller wouldn't budge. I took the pump out and found that the impeller was crooked against the seal plate. I was able to force it off and you can see in the picture below the amount of rubbing that was occurring. I am uncertain of how much more of the motor to take apart and work on due to the age.

Hoping an expert can guide as to whether this looks like it may be something easy to fix on the inside or to just move on to a new pump. It does seem that the motor is about 1/3 the cost of getting a new pump outright so perhaps it is worth replacing just the motor.

Appreciate your help!

Brian