Oh no, pump dying???

- Thread starter Katygreys

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

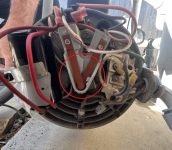

Yup for sure. Looks like it even might be damaged now if you look close. I will go have another look. I wonder why I would suddenly have a bearing issue after I replace the capacitors. Again, after I replace both capacitors in before I install the covers (and got pop and sparks) it sounded perfect

The wire looks damaged.

It looks like it was crushed.

Maybe it got snagged by the weights and stretched?

I don't know why the noise would happen suddenly.

Maybe a short went through the bearings and arcing damaged the bearings and caused them to fail?

It looks like it was crushed.

Maybe it got snagged by the weights and stretched?

I don't know why the noise would happen suddenly.

Maybe a short went through the bearings and arcing damaged the bearings and caused them to fail?

Ok. Just bought a Hayward 950 variable speed. I need to get it hooked up quickly. Keep in mind that my Prologic was previously set up to run a 2 speed pump. Until I have more time to get it set up and programmed into my automation, I would like to just give it constant power and control it manually from the control panel on the pump itself. I think I can do this by just having my pro logic think it’s on high-speed 24/7.

Below is a picture of the wires that were going to into my old 2 speed pump. I measured voltage across the wires in both high and low speed, and did not see any difference. Between white and blue is 240 V. Between white and black or black and blue it is 72 V. Again, no matter if in high or low speed. With filter set to off, it’s 0.5V across any two of the three wires.

So, can I just hook up say the white and blue wires into the new pump, tell my Prologic to run on high speed 24 seven and then control the operation of the pump on the pump control panel?

Also, kind of curious why both High and speeds show same voltage readings. How did the old pump know what speed to go in?

Below is a picture of the wires that were going to into my old 2 speed pump. I measured voltage across the wires in both high and low speed, and did not see any difference. Between white and blue is 240 V. Between white and black or black and blue it is 72 V. Again, no matter if in high or low speed. With filter set to off, it’s 0.5V across any two of the three wires.

So, can I just hook up say the white and blue wires into the new pump, tell my Prologic to run on high speed 24 seven and then control the operation of the pump on the pump control panel?

Also, kind of curious why both High and speeds show same voltage readings. How did the old pump know what speed to go in?

Can you show inside the box?

You can power the pump with 240 from the filter relay Load Terminals and set the pump as a 1 speed pump in the Filter Configuration Menu.

You can power the pump with 240 from the filter relay Load Terminals and set the pump as a 1 speed pump in the Filter Configuration Menu.

How To Wire A 2-Speed 230V Motor to a Hayward Pro Logic System - INYOPools.com

How To Wire A 2-Speed Motor to a Hayward Pro Logic System

Attachments

I also measured White to ground and blue to ground. Both are 124 V in both high and low speed. Black to ground is 2.1 V in both high and low speed. Pictures inside the box below. Based on this, just until my electrician buddy gets back from vacation, can I just hook up blue and white, tell my Prologic to run 24 seven, and control it from the pump panel?

I can't really follow everything you have going on.

You need to verify 230 volts for the pump supply.

Also the breaker needs to be GFCI.

You need to verify 230 volts for the pump supply.

Also the breaker needs to be GFCI.

I get 240V between white and blue regardless of pump speed. So I am thinking that if I use those wires to supply 240V, the pump will not know anything about the black wire that it's not connected to.

Thread Status

Hello , This thread has been inactive for over 60 days. New postings here are unlikely to be seen or responded to by other members. For better visibility, consider Starting A New Thread.