Those are two different types of cleaner. You first need to decide which cleaner you want. Suction side cleaners are good for pools that have small debris on the floor (small leaves and dirt), while a pressure side cleaner is better for pools with larger debris.

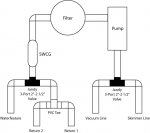

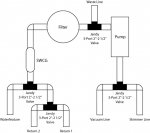

You cannot add a vacuum/suction line on to a return line. You can however put a pressure side cleaner on a return line. I think that is what you mean?

Yes, I meant installing a pressure side cleaner (for example, the Polaris 360) on a dedicated return line. The idea is to have that return line function as a standard return with an eyeball while not being used for vacuuming. If that works, I'll do that as I would like the extra return. Sounds like the best of both worlds to me! Am I missing something?

I don't have many large trees near the pool, only palms. I can't imagine anything other than small leaves or dirt at the bottom of my pool. Would the pressure side cleaner blow the dirt away instead of vacuuming?