- May 27, 2017

- 20

- Pool Size

- 30000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-40

My IntelliPh recently stopped working. Last month, I noticed that the pump was making a rough noise when running. Inspection revealed a very worn and hardened pump tube. Replaced the tube and the system went back to sounding normal while pumping.

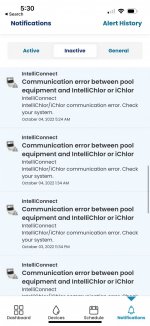

Checked the system last night, and the screen for the IntelliPh wasn't on. No red LED either. Power was passing through the IntelliPh controller just fine though, as my IntelliChlor was running OK and communicating with automation.

I opened up the IntelliPh controller and discovered a board burned in 3 places. I've attached the picture here. This feels similar to a previous post by @Turbo1Ton. But where he had burned pins, I have numerous components on the board burned out. And similar to that post, the fuse in the IntelliChlor power center never popped.

Anyone know what is going on here!?!? Is Pentair just pumping out bad boards? Of course the laughable warranty is over.

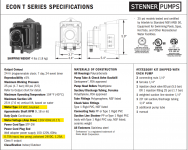

My worst fear is that the hardened tube caused the motor windings to burn. If the motor is drawing too much current, and the board doesn't have appropriate protection, I'll just burn the replacement. Anyone know how to check the motor for spec?

@Dirk any thoughts?

Thanks all!

Checked the system last night, and the screen for the IntelliPh wasn't on. No red LED either. Power was passing through the IntelliPh controller just fine though, as my IntelliChlor was running OK and communicating with automation.

I opened up the IntelliPh controller and discovered a board burned in 3 places. I've attached the picture here. This feels similar to a previous post by @Turbo1Ton. But where he had burned pins, I have numerous components on the board burned out. And similar to that post, the fuse in the IntelliChlor power center never popped.

Anyone know what is going on here!?!? Is Pentair just pumping out bad boards? Of course the laughable warranty is over.

My worst fear is that the hardened tube caused the motor windings to burn. If the motor is drawing too much current, and the board doesn't have appropriate protection, I'll just burn the replacement. Anyone know how to check the motor for spec?

@Dirk any thoughts?

Thanks all!