Hi all,

I will be installing a Intelliflo in 2 weeks time at the house in France.

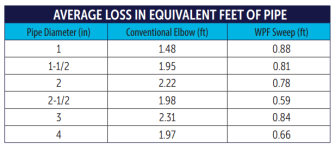

What is the best length from the outlet of the pump before a 180 down, I understand it's less then desirable to do an 180 for the flow but that is what i have and don't feel like ripping the floor open.

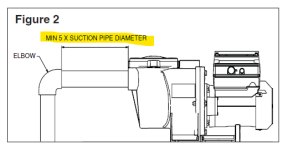

The inlet has to be 20" straight when entering the pump (2" line) , that i can make without a lot of hassle.

Here a picture of the old setup (still working) pump (1.5hp single speed 90gpm)

Any input greatly appreciated!

I will be installing a Intelliflo in 2 weeks time at the house in France.

What is the best length from the outlet of the pump before a 180 down, I understand it's less then desirable to do an 180 for the flow but that is what i have and don't feel like ripping the floor open.

The inlet has to be 20" straight when entering the pump (2" line) , that i can make without a lot of hassle.

Here a picture of the old setup (still working) pump (1.5hp single speed 90gpm)

Any input greatly appreciated!