Pool heaters can benefit from periodic cleaning.

Gas Heater

Heaters should be inspected at least once a year with panels coming off and looking for corrosion, leaks, and critters nets.

Heater Installation

A dealer may or may not have certified people to do the installation. They may just sub it out to someone they use to do plumbing work and then you’ll get the basic drop in and go. The dealer will certainly hold the warranty but that’s mostly meaningless after the fact.[1]

What we’ve seen happen time and again is that a person buys a heater and some “installer” shows up with it on their back of their pickup and the drop the unit in place. They then tell the the homeowner - “it’s all hooked up, we tested it, fired it up and it’s all good … please sign here on the line.” The heater works for a bit or the homeowner just isn’t watching it closely and then problems kick it. Maybe the gas pressure wasn’t tested and the heater will fire but not stay lit. Maybe the electrical install was wonky. Then you’re stuck after the fact trying the get the dealer to fix it while he’s trying to get Raypak to deal with it. Then you go through a half dozen “local repair” guys before you come back on TFP begging for help. At that point, @JamesW asks you a million questions with pictures and finally comes to the conclusion that the original installer is a dunce and they forgot to take the plastic plug out of the inlet on the manifold.

Save yourself the grief and demand that the installer be certified and be there looking over their shoulders while they do work. Ask for visual and written proof that the heater is operating within spec before you sign off any paperwork.

Heater Gas Sediment Trap

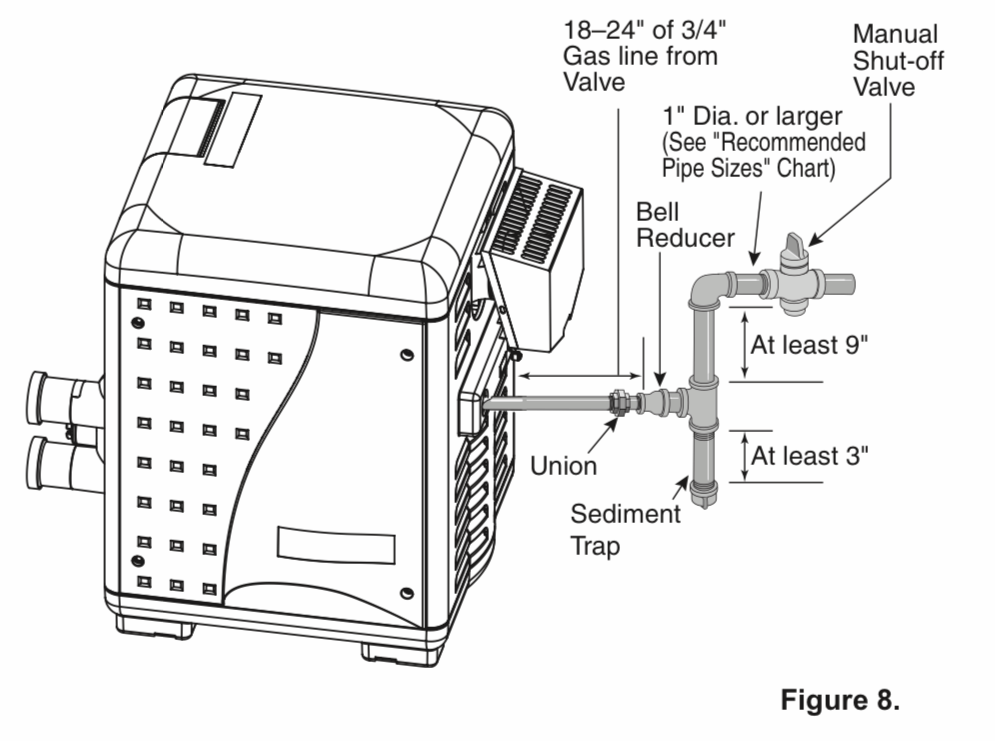

A gas heater should have a sediment trap before the gas line goes into the heater and gas valve.

The correct sediment trap design is for the gas to make a 90 degree turn to go into the heater while the sediment can drop down into the sediment traps as shown in the Pentair diagram below. We see many gas line installations that have the gas going straight and the sediment trap on a 90 degree bend. The sediment will not make that turn and continue into the as valve eventually causing it to fail.

The sediment trap below is incorrectly installed:

Cleaning

Most burners lift up from the end that is away from the gas manifold ( usually fitted into a slot at the far end) and push away from the gas manifold to remove off of the orifice on the manifold. They can then be cleaned with a wire brush and either blown out from the top slots or tipped towards the end that sits on the orifice to remove internal dirt.

Also check for spider webs at the end that sits on the orifice. Depending on the ignition source( spark/hot surface ignitor), you must be careful removing the burners.

If you have a silicon carbide hot surface ignitor, they are very fragile and susceptible to failure from bumps against a hard surface and even oil from your hands causing it to fail. Only handle from the white ceramic insulator at the end that the wires are attached to.

Orifices can be cleaned out with a pipe cleaner to remove spider webs or other blockages.

After the ignition source and burners are removed you will need to look up through the heat exchanger with a mirror and flashlight to see if there is any black carbon/soot restricting the flow through the heat exchanger. If there is, the heater would need to be disassembled and cleaned to remove the blockage. This should probably only be attempted by a professional if needed.

Most HVAC companies will work on a pool heater, but not all HVAC technicians are created equal. If needed, look for a company that has NATE certified technicians ( this applies to HVAC service also)!

Heat Pumps

Cleaning

A Heat Pump is an an air conditioner system that works in reverse. It can benefit from annual cleaning of it's coils and air vents.

Motors and Capacitors

A Heat Pump has motors for the compressor and fan. Like pool pumps the motors in a Heat Pump has capacitors that can fail. See Pump Capacitors for more information about motor capacitors.

Refrigerant

The Heat Pump also contains refrigerant, like an air conditioning system. You need to find a maintenance company who is licensed if you are accessing/opening the refrigerant part of the system.

Water Flow Rate

Running too much water through a gas heater is a bad idea. There's an internal bypass that bypasses over a certain amount anyway. So, it's a waste of energy.[2]

Excessive flow velocity can erode the soft copper in the heat exchanger.

Efficiency is only slightly better at higher flow. As long as the flow is above the minimum specified flow rate, increasing the flow rate does not provide any significant benefits.

Heater Pressure Switch

Heaters, gas and electric heat pumps, use a pressure switch and not a flow switch to determine that it has water flow to safely operate. Under some installation conditions a pressure switch will not safely sense when there is not water flow and a flow switch is needed.

Pressure switches are some of the simplest and most robust parts of any pool heater and seldom, if ever, need adjusting.[3]

Pool heater 101, 90% of all service calls on heaters have nothing to do with the heater, the issues are caused by water flow problems. That was one of the first things that Laars (now Jandy), RayPak, and Hayward heater schools all taught. A heater working at 1600 RPM may have been right at the bare minimum required and anything that could cause even a slight reduction in flow would not allow the heater to fire. Even a "clean" filter may not be "new clean." A specific RPM does not always mean the same amount of flow.

You typically set any pool that is heated first by finding the minimum flow required to get the switch to close (heater to fire) with a clean filter. The key is starting with a known clean filter. It also depends on whether the pump is a high-head, like an Intelliflo, or medium head like a SuperFlo.

With a high head pump you should add at least 15% more default RPM just to account for the filter getting dirty so it will still have enough flow and not have short cycling because of a flow issue. At the bare minimum RPM a pressure switch can "bounce" from slight variations in flow causing the heater to cycle on and off.

With a medium-head pump you should add at least 20% more because they lose more flow with an increase in pressure (head). Sometimes that isn't enough. That's one reason some pool companies do not use or recommend a medium-head pump for filtration except on the simplest pools and a customer with a very limited budget.

New pumps are amazing things, but the actual pumping technology is very old. The Intelliflow is still based on the 30 year-old Whisperflow design. The IntelliPro (Sta-Rite version) is still based on a 30 year old Max-E-Pro design. Sta-Rite "Pump University" used to have very good classes before Pentair bought them. Simplest definition is that a high-head pump's flow will not drop more than 10% with a 10 lb. rise in pressure, a medium-head pump will drop 20% or more with the same rise in pressure. Adjust accordingly.

Heater Outlet Temperature Rise

Heater outlet temperature rise will depend on the water flow rate. Slower water flow will have greater outlet temperature since the same BTUs go into less water volume.

Changing the pump speed can vary the return temperature from just warm at high RPM to very hot at minimum flow for the heater.

For example, a 400,000 btu/hr heater with an efficiency of 84% transfers 336,000 btu per hour to the water.[4]

At a minimum required flow of 40 gpm, there will be 2,400 gallons of water (20,000 lbs.) that receives the heat.

Each btu raises the temperature of one pound of water by one degree Fahrenheit.

336,000 btu into 20,000 pounds of water is 16.8 degrees of temperature rise (336,000/20,000).

So, the maximum temperature rise you should ever have is 16.8 degrees Fahrenheit.

As shown below, higher flow results in a lower temperature rise.

- 40 gpm = 16.8 degrees temperature rise

- 50 gpm = 13.44 degrees temperature rise

- 60 gpm = 11.2 degrees temperature rise

- 70 gpm = 9.6 degrees.

- 80 gpm = 8.4 degrees.

On all pool heaters there are temperature limit switches, the first one is usually set to trip (turn the heater off) if the water temperature, in the manifold and leaving the heater, is in the 125 - 130 degree F range (that's coffee-hot). The second is usually set to between 135 - 140 degree F range (that's hot-coffee-hot). This is dependent on the manufacturer of the heater. You really don't want either of those temperature waters hitting you directly.[5]

Not all the water going into the heater actually goes through the heat exchanger, there is always an internal bypass that allow just the right amount to go through and then mix back with the cooler bypassed pool water and enter the pool or spa. What this does is produce a temperature rise each time the water passes through the heater. On many gas heaters it will be about 15 degrees. A 15-degree temperature difference is what you are calling luke-warm, it doesn't feel like much, but that is how it is supposed to feel at first. The heater just keeps adding that much more heat to the body of water until it reaches the set point.

So, when the spa first starts heating in the winter, the water goes into the heater at maybe 45 degrees and comes out at 60, that would feel warmer, but just barely. By the time the water hits 100 (the starting temp most people like in a spa) it would come out at 115, that's where we start feeling really hot water coming from the heater (approaching coffee-hot) and don't always like sitting close to a jet.

By law, a pool heater can't be set to heat above 104. That means the maximum outlet temperature entering the spa could be about 119 just before the heater turned off as the spa water reaches the setpoint. That's usually uncomfortable to sit right at the jet, and close to tripping one of the hi-limits in the system.

.

- ↑ https://www.troublefreepool.com/threads/new-natural-gas-heater.276353/post-2422750

- ↑ https://www.troublefreepool.com/threads/speed-for-solar.195330/post-1721984

- ↑ https://www.troublefreepool.com/threads/raypak-336a-low-flow-pressure-switch-failure-mode.272537/post-2389518

- ↑ https://www.troublefreepool.com/threads/temperature-of-water-exiting-pool-heater.223090/post-1954740

- ↑ https://www.troublefreepool.com/threads/heater-max-etherm-400.266051/post-2328573