I have a safety cover that was installed into my concrete pool deck. I just had my deck resurfaced with 2" unilock pavers over the concrete. The paver joints have polymeric sand in them. I'm told the correct way to re-install cover anchors is to drill into the joint of 3 pavers, through the pavers and concrete subdeck, and drive a 9" lawn anchor through everything. But they are EXPENSIVE! I need 36 of them, and we're talking almost $500.

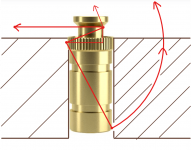

My thought is to purchase my own aluminum pipe (1" outer diameter / 0.75" inner diameter), cut it to 7" long pieces (the total depth of my pavers plus concrete), tap regular brass safety cover anchors into the pipe, and then drive them through both the paves and concrete with a wood block. This should save me about $200 and it gives me the correct length pipe. Once it's through the concrete, I can't imagine it would need to be any longer.

Can anyone think of anything wrong with this approach? When I look at the pre-made anchors in pipe, they look like a regular brass anchor inserted into pipe. I'm not sure if there's any more to it than that.

My thought is to purchase my own aluminum pipe (1" outer diameter / 0.75" inner diameter), cut it to 7" long pieces (the total depth of my pavers plus concrete), tap regular brass safety cover anchors into the pipe, and then drive them through both the paves and concrete with a wood block. This should save me about $200 and it gives me the correct length pipe. Once it's through the concrete, I can't imagine it would need to be any longer.

Can anyone think of anything wrong with this approach? When I look at the pre-made anchors in pipe, they look like a regular brass anchor inserted into pipe. I'm not sure if there's any more to it than that.

Last edited:

Let's try to keep this thread active with replies and get some others to chime-in with their thoughts. Perhaps we can strong-arm

Let's try to keep this thread active with replies and get some others to chime-in with their thoughts. Perhaps we can strong-arm