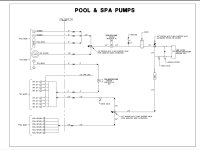

OK, so if you separate the jets in the spa into two different pump circuits, how do you plumb the loops around the spa for each circuit? It would seem at some point you would need to have the lines pass by one another and it would take up too much room in the spa wall. Are you not running loops for the plumbing? Do you have any pictures of how the spa is plumbed?A typical pool/spa system that I advise customers to consider is a XF Pentair pump for the main pool pump (80 more GPM plumbed with 2 1/2 “ pipe) that will run up to 8 jets in the spa alone. Then a second pump VS Pentair for an additional 6-8 jets (plumbed with 3” pipes).

When the homeowners are using the spa alone (2-people) the main pool pump is in service running 8 jets plumbed through the heater, when more people are in the spa the dedicated spa booster pump is activated to run the other jets that only recirculate the heated spa water.

Have not personally seen a system that runs the spa booster pump through the heater along with the pool/spa pump.

Traditional air venturi vs blower for spa

- Thread starter Brant

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- May 3, 2007

- 16,964

- Pool Size

- 20000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite (T-15)

Are you planning to add more jets?

Normally, a two pump solution like that is for more than 8 jets and usually an upper/lower configuration so the loops do not have to cross.

What you need to decide on first, is how many stations (i.e. supported users) you want, how many jets per station and the jet nozzle size. Then you decide how to plumb it based upon the jet requirements.

Normally, a two pump solution like that is for more than 8 jets and usually an upper/lower configuration so the loops do not have to cross.

What you need to decide on first, is how many stations (i.e. supported users) you want, how many jets per station and the jet nozzle size. Then you decide how to plumb it based upon the jet requirements.

AQUA~HOLICS

In The Industry

AQUA~HOLICS

In The Industry

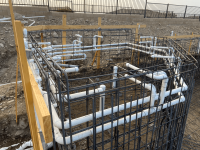

You can see how the two different looped systems are not connected together but are plumbed ontop of each other.

- May 3, 2007

- 16,964

- Pool Size

- 20000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite (T-15)

A 2.5" suction pipe should not exceed 6 ft/sec per regulations which is 90 GPM. What size spa jets are you using? 15 GPM jets will well exceed 90 GPM depending on other system head loss.A typical pool/spa system that I advise customers to consider is a XF Pentair pump for the main pool pump (80 more GPM plumbed with 2 1/2 “ pipe) that will run up to 8 jets in the spa alone.

With 8 jets @ 15 GPM each, I would not recommend anything less than 3" pipe.

i was considering having 10 jets max. two 3 jet gunite bodies and 4 single jet bodies. i figure that with both pumps on, i should be able to get at least 170 gpm combined so that would give me 17 gpm each which seems more than enough.

also, i believe if i run a 2.5" spa loop or two 2" loops connected to one another, that would be able to handle the flow and not be excessivei was considering having 10 jets max. two 3 jet gunite bodies and 4 single jet bodies. i figure that with both pumps on, i should be able to get at least 170 gpm combined so that would give me 17 gpm each which seems more than enough.

as mentioned, 6 stations. 2 stations with 3 jet body and 4 stations with single jets. i intend to put the same size orifices in each jet so they should all need the same volume of water.Are you planning to add more jets?

Normally, a two pump solution like that is for more than 8 jets and usually an upper/lower configuration so the loops do not have to cross.

What you need to decide on first, is how many stations (i.e. supported users) you want, how many jets per station and the jet nozzle size. Then you decide how to plumb it based upon the jet requirements.

i think the best way to ensure i have maximum and balanced flow from every jet in the system is to have them all supplied from the same loop(s) with both pumps combined. this would allow me to increase or decrease flow and keep everything balanced. im not trying to run half the jets at a time. i am fine with it being all or nothing.

- May 3, 2007

- 16,964

- Pool Size

- 20000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite (T-15)

If you are ok with running both pumps all the time, then that should be fine but I would go with two separate loops for each pump as it will give you more flexibility.

Loop #1: 4 single jets to main circulation loop with filter/heater, 3" suction/return

Loop #2: 2x3 Manifolds to second dedicated pump, 3" suction/return

Plus, separate 2.5" air lines for each.

The single jets will most likely be plumbed at a different height than the water/air lines for the manifolds so that should be a non-issue.

Loop #1: 4 single jets to main circulation loop with filter/heater, 3" suction/return

Loop #2: 2x3 Manifolds to second dedicated pump, 3" suction/return

Plus, separate 2.5" air lines for each.

The single jets will most likely be plumbed at a different height than the water/air lines for the manifolds so that should be a non-issue.

so could i do 2" pipe for each loop?If you are ok with running both pumps all the time, then that should be fine but I would go with two separate loops for each pump as it will give you more flexibility.

Loop #1: 4 single jets to main circulation loop with filter/heater, 3" suction/return

Loop #2: 2x3 Manifolds to second dedicated pump, 3" suction/return

Plus, separate 2.5" air lines for each.

The single jets will most likely be plumbed at a different height than the water/air lines for the manifolds so that should be a non-issue.

- May 3, 2007

- 16,964

- Pool Size

- 20000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite (T-15)

I would use 3" to/from the spa and 2.5" around the spa after the 3" splits into 2. To keep jets at full strength, you want to reduce head loss in the rest of the plumbing as much as possible. Plus upsizing pipe should not cost you much. For a gunite pool, the wall depth is at least 8" and sometimes up to 12" thick so plenty of room for the pipe.

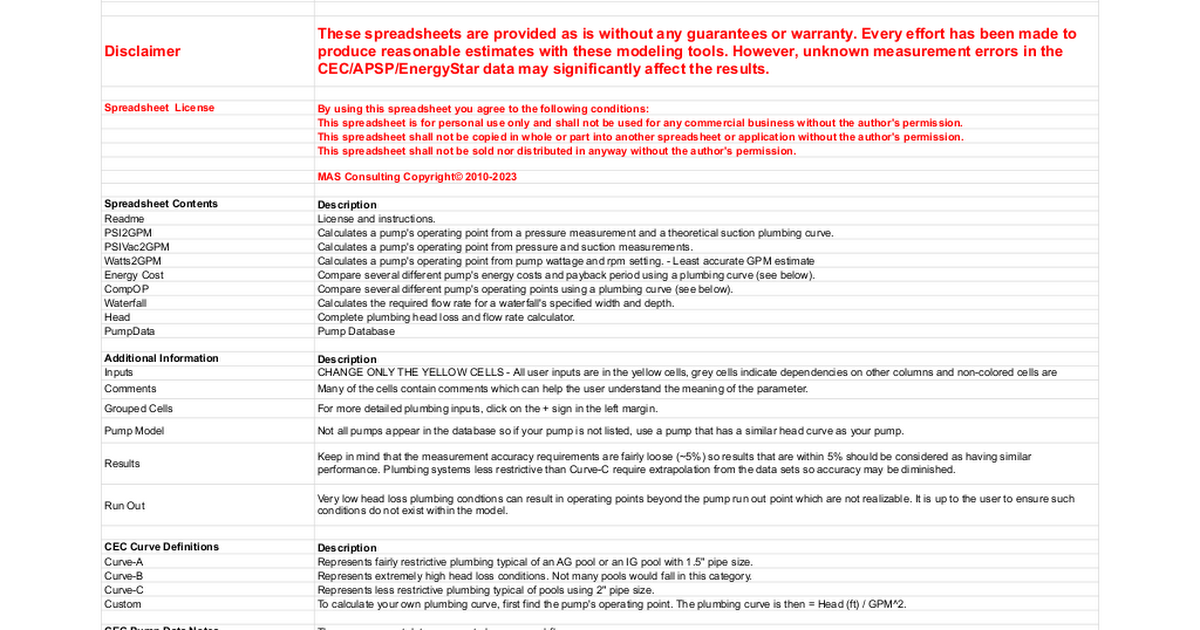

I put together a head loss model for the two loop system:

docs.google.com

docs.google.com

There are two cases for each loop. A 3/8" jet and a 7/16" jet. For loop #1, I assumed the bypass is on for a lower head loss configuration.

Loop#1 3/8: 18.3 GPM/Jet, 2.1 lbf

Loop#2 3/8: 18.0 GPM/Jet, 2.0 lbf

Loop#1 7/16: 22.5 GPM/Jet, 2.3 lbf

Loop#2 7/16: 22.0 GPM/Jet, 2.2 lbf

The 7/16" jets would feel a little bit stronger but not by a lot.

I put together a head loss model for the two loop system:

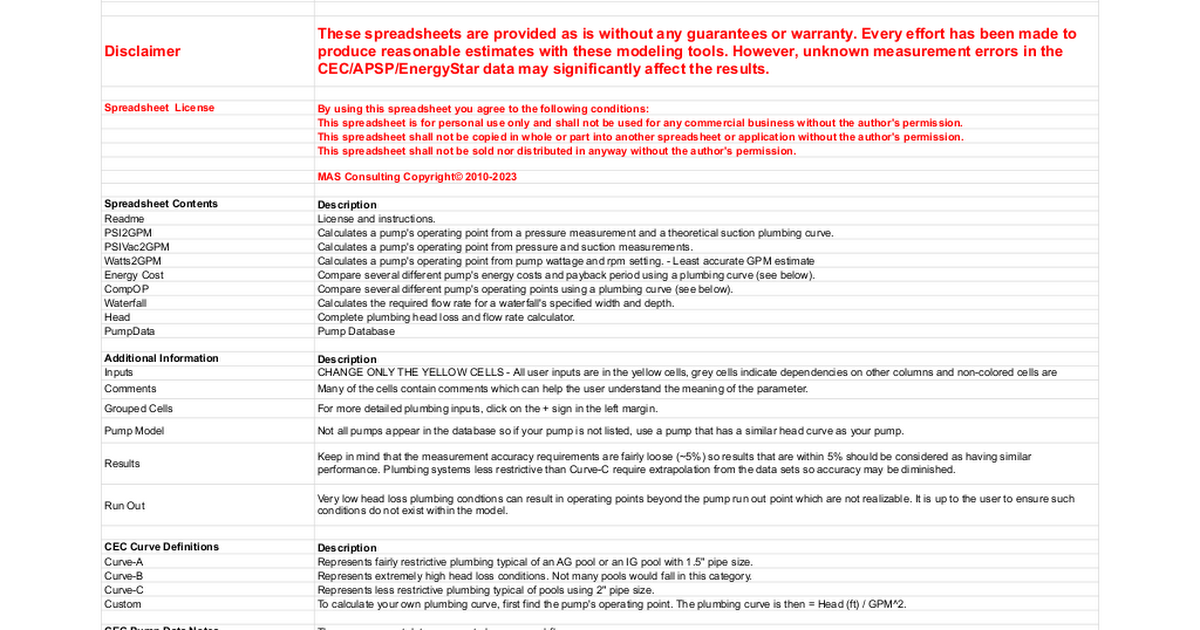

Pool Pump Tools v028 - Brant

ReadMe Version:,v028 Disclaimer,These spreadsheets are provided as is without any guarantees or warranty. Every effort has been made to produce reasonable estimates with these modeling tools. However, unknown measurement errors in the CEC/APSP/EnergyStar data may significantly affect the results...

There are two cases for each loop. A 3/8" jet and a 7/16" jet. For loop #1, I assumed the bypass is on for a lower head loss configuration.

Loop#1 3/8: 18.3 GPM/Jet, 2.1 lbf

Loop#2 3/8: 18.0 GPM/Jet, 2.0 lbf

Loop#1 7/16: 22.5 GPM/Jet, 2.3 lbf

Loop#2 7/16: 22.0 GPM/Jet, 2.2 lbf

The 7/16" jets would feel a little bit stronger but not by a lot.

AQUA~HOLICS

In The Industry

on the spreadsheet. what does the number 1 signify in the filter type? is there a chart for different types of filters on this spreadsheet?I would use 3" to/from the spa and 2.5" around the spa after the 3" splits into 2. To keep jets at full strength, you want to reduce head loss in the rest of the plumbing as much as possible. Plus upsizing pipe should not cost you much. For a gunite pool, the wall depth is at least 8" and sometimes up to 12" thick so plenty of room for the pipe.

I put together a head loss model for the two loop system:

Pool Pump Tools v028 - Brant

ReadMe Version:,v028 Disclaimer,These spreadsheets are provided as is without any guarantees or warranty. Every effort has been made to produce reasonable estimates with these modeling tools. However, unknown measurement errors in the CEC/APSP/EnergyStar data may significantly affect the results...docs.google.com

There are two cases for each loop. A 3/8" jet and a 7/16" jet. For loop #1, I assumed the bypass is on for a lower head loss configuration.

Loop#1 3/8: 18.3 GPM/Jet, 2.1 lbf

Loop#2 3/8: 18.0 GPM/Jet, 2.0 lbf

Loop#1 7/16: 22.5 GPM/Jet, 2.3 lbf

Loop#2 7/16: 22.0 GPM/Jet, 2.2 lbf

The 7/16" jets would feel a little bit stronger but not by a lot.

- May 3, 2007

- 16,964

- Pool Size

- 20000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite (T-15)

There is supposed to be a comment there but it is gone for some reason. Here are the definitions:

Filters

0 - None

1 - Cartridge/DE/>5sqft->30" Sand

2 - 3 sqft-24" Sand

2.5 - 2.5 sqft-20" Sand

5 - 2 sqft-19" Sand

These do not include the MPV if you are going with a DE or sand. That is in line 41:

MPV

0 - None

1 - 2" Valve

2 - 1.5" Valve

Filters

0 - None

1 - Cartridge/DE/>5sqft->30" Sand

2 - 3 sqft-24" Sand

2.5 - 2.5 sqft-20" Sand

5 - 2 sqft-19" Sand

These do not include the MPV if you are going with a DE or sand. That is in line 41:

MPV

0 - None

1 - 2" Valve

2 - 1.5" Valve

a few questions/concerns...I would use 3" to/from the spa and 2.5" around the spa after the 3" splits into 2. To keep jets at full strength, you want to reduce head loss in the rest of the plumbing as much as possible. Plus upsizing pipe should not cost you much. For a gunite pool, the wall depth is at least 8" and sometimes up to 12" thick so plenty of room for the pipe.

I put together a head loss model for the two loop system:

Pool Pump Tools v028 - Brant

ReadMe Version:,v028 Disclaimer,These spreadsheets are provided as is without any guarantees or warranty. Every effort has been made to produce reasonable estimates with these modeling tools. However, unknown measurement errors in the CEC/APSP/EnergyStar data may significantly affect the results...docs.google.com

There are two cases for each loop. A 3/8" jet and a 7/16" jet. For loop #1, I assumed the bypass is on for a lower head loss configuration.

Loop#1 3/8: 18.3 GPM/Jet, 2.1 lbf

Loop#2 3/8: 18.0 GPM/Jet, 2.0 lbf

Loop#1 7/16: 22.5 GPM/Jet, 2.3 lbf

Loop#2 7/16: 22.0 GPM/Jet, 2.2 lbf

The 7/16" jets would feel a little bit stronger but not by a lot.

would each jet loop need it's own air supply or could all 10 jets be fed off of one 2.5" air line?

because of design constraints, all the plumbing is going to come up from the floor. i'm a little concerned how i get the main lines to pass by the lower water loops. the 2.5" air line will need to pass by two 2.5" water loops and the upper water loop main supply line will need to pass by the lower 2.5" water loop. i can probably put the lower water loop below the seat so there will be sufficient gunite in this area but where the lines pass by one another in the upper wall areas, i feel that this might compromise the wall integrity. i'm planning on 12" walls. the OD of 2.5" PVC is just under 3". so can i get away with 3" of gunite on either side and still be safe?

- May 3, 2007

- 16,964

- Pool Size

- 20000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite (T-15)

I would plumb separate air lines. Otherwise if one pump was running and the other was not, water would come out of one of the air lines. That could also happen if the flow rates are substantially different between the two pumps which they are so it would be better to have them separated to prevent any issues.a few questions/concerns...

would each jet loop need it's own air supply or could all 10 jets be fed off of one 2.5" air line?

The suction ports can go horizontal until they clear the spa wall and then rise up outside of the wall. They do not need to go vertical inside the spa wall. All of these pipes will eventually clear the wall anyway so they don't all need to be embedded in the wall to a single location. That actually creates a weaker point. It is better to come out of the wall at different locations anyway.because of design constraints, all the plumbing is going to come up from the floor. i'm a little concerned how i get the main lines to pass by the lower water loops. the 2.5" air line will need to pass by two 2.5" water loops and the upper water loop main supply line will need to pass by the lower 2.5" water loop. i can probably put the lower water loop below the seat so there will be sufficient gunite in this area but where the lines pass by one another in the upper wall areas, i feel that this might compromise the wall integrity. i'm planning on 12" walls. the OD of 2.5" PVC is just under 3". so can i get away with 3" of gunite on either side and still be safe?

BTW, The Hartford loops do not need to be in the spa wall as long as they are fairly close to the spa. I have seen them in landscaping about 10' from the spa and they still allow for non-blower operation.

The largest issue is when the spa water level is higher in elevation than the lowest point of the air line by more than few feet so the entire length of air pipe fills with water. Venturis struggle to clear the lines when the elevation difference is more than about 3'.

A decent plumber should be able figure all this out for you. But to ease your mind, this is done all the time and there are many examples on the forum. Ask the PB for a plumbing design and we can vet if for you.

the issue is that the spa is raised above ground, not buried. there is no option to come in from the side so it needs to come up vertically inside the spa wall from the floor. the only areas to run the lines other than the spa wall is inside the spa seat/bench area.The suction ports can go horizontal until they clear the spa wall and then rise up outside of the wall. They do not need to go vertical inside the spa wall. All of these pipes will eventually clear the wall anyway so they don't all need to be embedded in the wall to a single location. That actually creates a weaker point. It is better to come out of the wall at different locations anyway.

- May 3, 2007

- 16,964

- Pool Size

- 20000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite (T-15)

It's bagged up with a footer on two sides, tanning ledge on one side and pool on the other. The deck on the side is already bagged and filled. I don't want to destroy all the bagging work to run lines.However, the bottom of the spa is below ground level, no?