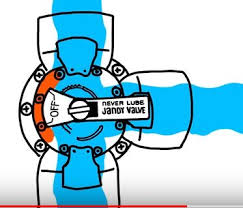

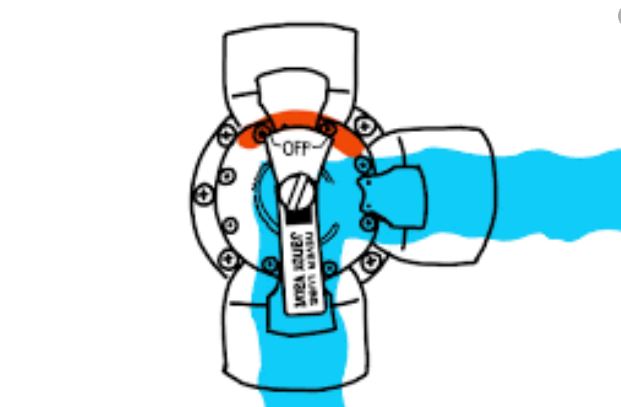

I have some questions about three way PVC ball valves. You have a lever that controls which way the water is being diverted to branch "A" or "B".

I have a few of these made by Jandy and typically the way I use it is to set the return line to go to "A" the pool or to "B" which may be the spa, or in between the pump and the filter to continue on, or open the waste line to remove water from the pool/spa.

The questions:

(1) Are these valves designed such that the lever may be set to divert water to both branches at the same time? Let me explain, if I have a fish pond and I have a pump and a return line to the pond, and I use a three way ball valve, where "A" goes to say a rock boulder and a waterfall feature, and "B" goes to a fountain aerator. Sometimes I want to run "A" only, and sometimes I want to run "B" only, but there may be times I want to run both A and B, and would I be able to turn the lever half way between A and B, or even play with where the lever needs to be to regulate the flow to both may be 70/30, 60/40 and keep it in that position to run both features? Or these valves are not designed for such usages and when I turn the lever to a spot in between A and B, the hole in the ball may be completely blocked so that no flow may be occurring?

(2) These valves comes in different materials, some says CPVC, some says PVC, if my piping is in PVC, my understanding is the strongest connection is to use PVC to PVC to get true solvent welding, but if the valves are CPVC, then I need to use a special glue intended to join CPVC to PVC, and that is a weaker joint then solvent welding PVC to PVC, is this correct? For example, if you look at this Amazon link:

The title says "Hayward PSV3S2 CPVC 3-Way Diverter Valve" so it's clearly a CPVC valve right? Then further down in the details it says "Material Polyvinyl Chloride (PVC)", seems they are using the two interchangeably?

I have a few of these made by Jandy and typically the way I use it is to set the return line to go to "A" the pool or to "B" which may be the spa, or in between the pump and the filter to continue on, or open the waste line to remove water from the pool/spa.

The questions:

(1) Are these valves designed such that the lever may be set to divert water to both branches at the same time? Let me explain, if I have a fish pond and I have a pump and a return line to the pond, and I use a three way ball valve, where "A" goes to say a rock boulder and a waterfall feature, and "B" goes to a fountain aerator. Sometimes I want to run "A" only, and sometimes I want to run "B" only, but there may be times I want to run both A and B, and would I be able to turn the lever half way between A and B, or even play with where the lever needs to be to regulate the flow to both may be 70/30, 60/40 and keep it in that position to run both features? Or these valves are not designed for such usages and when I turn the lever to a spot in between A and B, the hole in the ball may be completely blocked so that no flow may be occurring?

(2) These valves comes in different materials, some says CPVC, some says PVC, if my piping is in PVC, my understanding is the strongest connection is to use PVC to PVC to get true solvent welding, but if the valves are CPVC, then I need to use a special glue intended to join CPVC to PVC, and that is a weaker joint then solvent welding PVC to PVC, is this correct? For example, if you look at this Amazon link:

The title says "Hayward PSV3S2 CPVC 3-Way Diverter Valve" so it's clearly a CPVC valve right? Then further down in the details it says "Material Polyvinyl Chloride (PVC)", seems they are using the two interchangeably?