- May 23, 2015

- 24,447

- Pool Size

- 16000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

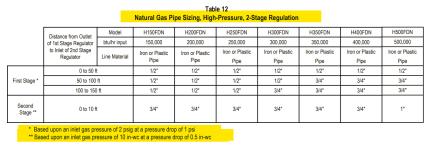

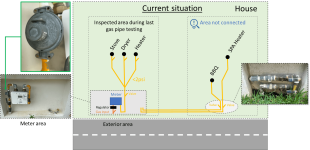

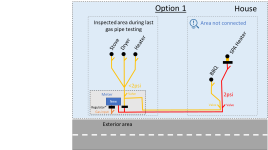

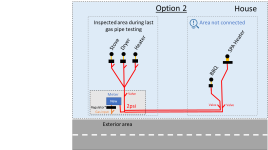

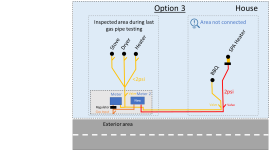

Considering the heater seems to be seated for long time and the previous owner never worry about it, It could means that the pipe line or gas installation could be the reason and I would like to be sure if it even possible before investing more on the heater. However, for that gas installation it will probably be required an operational heater for testing. May be wrong.

When you tested the gas line, was it disconnected from the meter and the heater, capped at both ends, and pressurized to 15psi (approximately) using air pressure? When my gas line was installed we ensured it held 15psi overnight. If your line has even the smallest leak, you will see 15psi move lower very quickly.

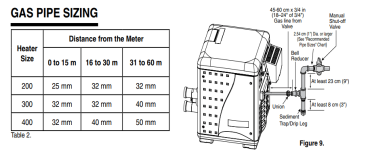

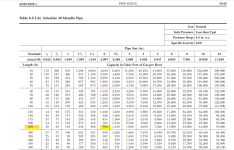

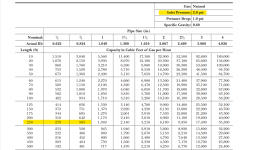

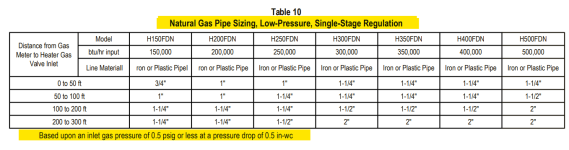

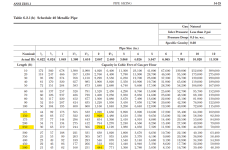

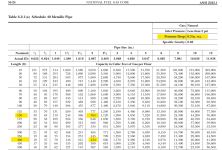

Do you know the diameter of the gas line used?

Do you know the run length of the gas line from the meter to the equipment pad?