So we are building a house and also having pool built along side of house. We are not moved in yet and pool people are still working on hardscape, so pool builder is having their person get water balanced and maintained at the moment.

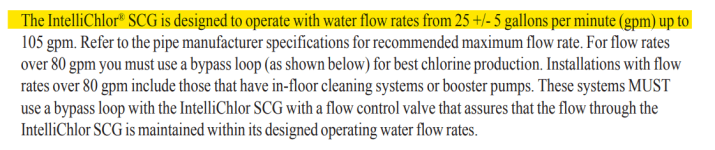

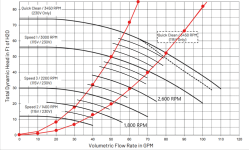

I, however, have been reading as much info about pool upkeep and maintenance as possible anticipating the time when I will take over. They just got the salt in the pool and the SWG running. The pump has been running on a higher RPM so I wanted to see how low I could take the pump and still get adequate flow for SWG. I was expecting somewhere around 1300-1500 RPM’s as this is what I seem to see most say they run their variable speed pump at. I was not able to go below 1900 RPM’s. I would get a red light on the flow sensor any lower. So I’m thinking I’d at least have to run at or just over 2,000 RPM’s to make sure SWG is always getting good water flow.

Is this normal? I also read that having a heater would require higher RPM’s to get good flow. If this is true, is it also still true if heater to not on?

And something else, can a SWG cause tiny bubbles to come out of return lines? I had tiny bubbles coming from all three return lines today. This is the first day the SWG had been fully functional and I have definitely not noticed any bubbles prior to today. Pool guy had SWG in super chlorine mode.

I, however, have been reading as much info about pool upkeep and maintenance as possible anticipating the time when I will take over. They just got the salt in the pool and the SWG running. The pump has been running on a higher RPM so I wanted to see how low I could take the pump and still get adequate flow for SWG. I was expecting somewhere around 1300-1500 RPM’s as this is what I seem to see most say they run their variable speed pump at. I was not able to go below 1900 RPM’s. I would get a red light on the flow sensor any lower. So I’m thinking I’d at least have to run at or just over 2,000 RPM’s to make sure SWG is always getting good water flow.

Is this normal? I also read that having a heater would require higher RPM’s to get good flow. If this is true, is it also still true if heater to not on?

And something else, can a SWG cause tiny bubbles to come out of return lines? I had tiny bubbles coming from all three return lines today. This is the first day the SWG had been fully functional and I have definitely not noticed any bubbles prior to today. Pool guy had SWG in super chlorine mode.