Couple questions before I start cutting pipes

Pump and filter sit under the deck today, and that's fairly convenient for power etc, and is where the plumbing enters/exits the ground.Heater sits about 20 feet way, outside of the fenced area, and out from under the deck. Was the only place we could put it that satisfied code etc.

Plan next year is to replace the ancient AC compressor and put the new one onto this same pad, as it's currently under the deck, which is wrong in so many ways.

The Puck-feeder was installed when they put the heater in, before I found TFP, and has never had a puck in it.

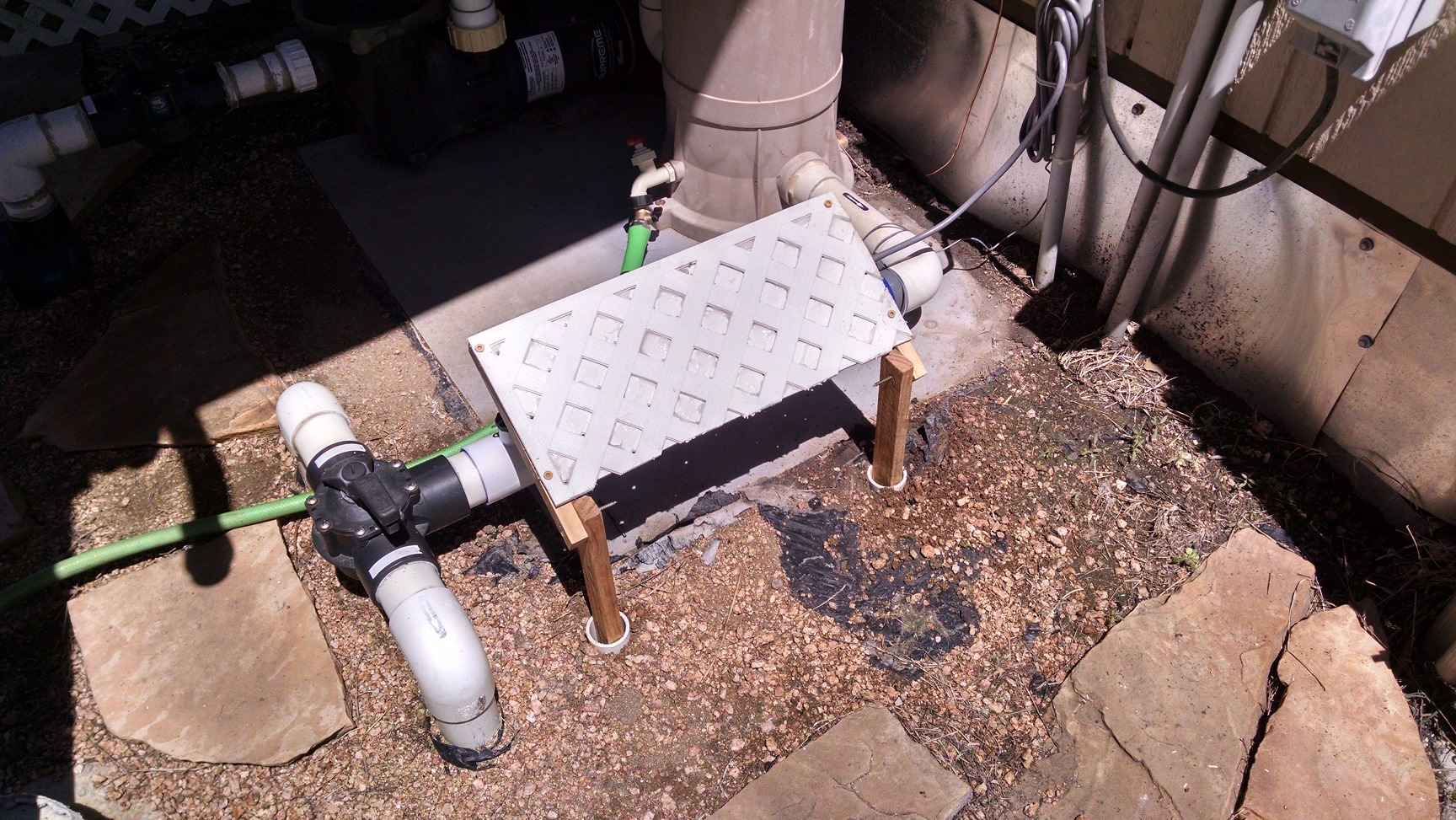

Left pipe is FROM the pump/filter - Right side is out to the pool (nothing after this).

There is not enough vertical height to fit the SWG cell in the existing down pipe (A) with the required 12" free-flow, and would be tight after the existing bottom 90 too (26" total there before the fence - (B) ) and there is no pipe to join to there anyway.

Thinking replace the down-90 (C) after the check valve (I think there is just enough pipe to work with there) with a horizontal 90 'away' from the fence, then a 90/90 to take it back toward the fence with enough room to install the cell, flow switch etc. Is there any issue with the cell being out in the sun ? The Control unit would be mounted to the wall to the left of the heater.

Other than that, water balance seems ready to go - my CYA is a little low (have some stabilizer marinating in a sock as we speak) and TA is a little high - not sure if I should be overly concerned with that other than just add a little acid and let it work it's way down.

FC : 7

CC: 0

CYA : 60

PH: 7.5

TA: 120

CH: 75

SALT : 3600

TEMP : 88

Pump and filter sit under the deck today, and that's fairly convenient for power etc, and is where the plumbing enters/exits the ground.Heater sits about 20 feet way, outside of the fenced area, and out from under the deck. Was the only place we could put it that satisfied code etc.

Plan next year is to replace the ancient AC compressor and put the new one onto this same pad, as it's currently under the deck, which is wrong in so many ways.

The Puck-feeder was installed when they put the heater in, before I found TFP, and has never had a puck in it.

Left pipe is FROM the pump/filter - Right side is out to the pool (nothing after this).

There is not enough vertical height to fit the SWG cell in the existing down pipe (A) with the required 12" free-flow, and would be tight after the existing bottom 90 too (26" total there before the fence - (B) ) and there is no pipe to join to there anyway.

Thinking replace the down-90 (C) after the check valve (I think there is just enough pipe to work with there) with a horizontal 90 'away' from the fence, then a 90/90 to take it back toward the fence with enough room to install the cell, flow switch etc. Is there any issue with the cell being out in the sun ? The Control unit would be mounted to the wall to the left of the heater.

Other than that, water balance seems ready to go - my CYA is a little low (have some stabilizer marinating in a sock as we speak) and TA is a little high - not sure if I should be overly concerned with that other than just add a little acid and let it work it's way down.

FC : 7

CC: 0

CYA : 60

PH: 7.5

TA: 120

CH: 75

SALT : 3600

TEMP : 88