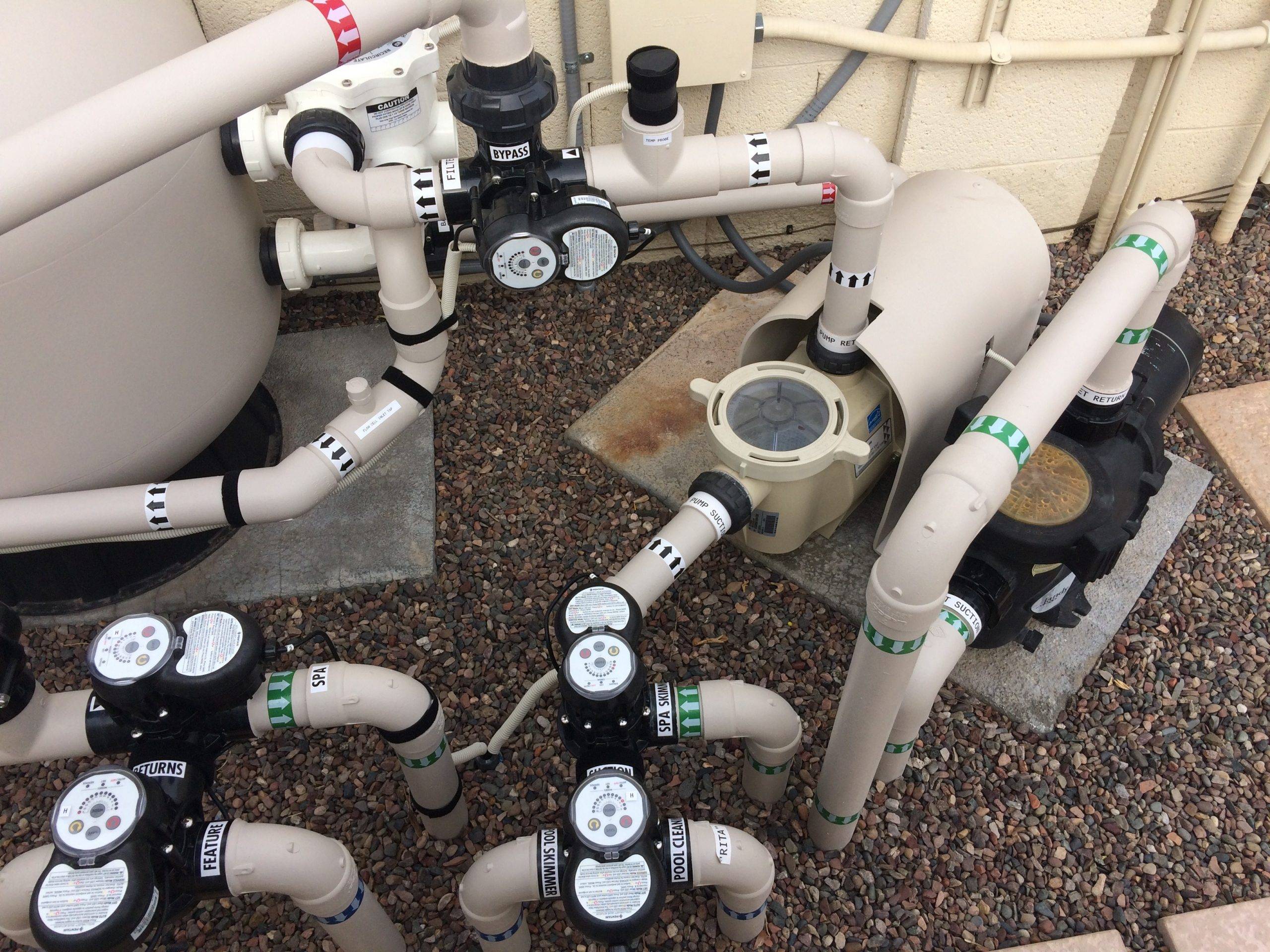

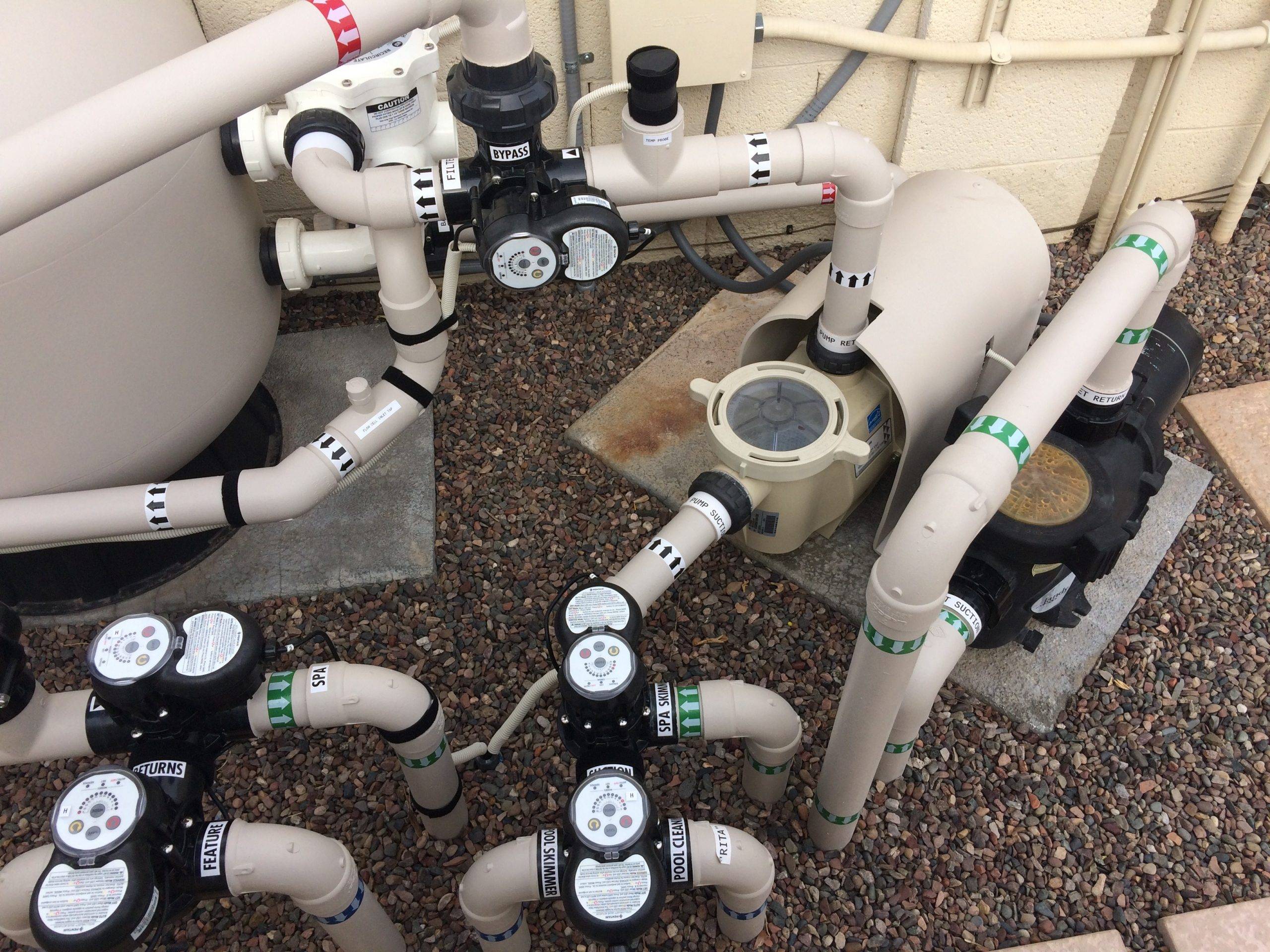

Newbie here - I'm trying to figure out a schedule for my Pentair SuperFlo VSP. The builder set it to run at 2500rpm 24/7 and he told me I can just leave it there, but I want to understand my numbers and fine-tune it anyway. First step for me is to calculate the flow by measuring pressure and vacuum from the ports on my pump. I bought a couple "standard" gauges but the ports on the pump are so low to the ground that I don't have enough room to screw in the gauges. Can I just connect my gauges to a hose and then connect the hose to the pump ports? Will that still give accurate readings?

Pressure and Vacuum Gauge Connections

- Thread starter kawisser

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Jun 22, 2014

- 47,855

- Pool Size

- 17888

- Surface

- Fiberglass

- Chlorine

- Salt Water Generator

- SWG Type

- CircuPool RJ-45 Plus

Welcome to TFP!  I suppose this is one of those topics you can experiment with or make things as easy (or difficult) as you wish. Running 24/7 is fine for many, but generally we recommend running pumps on the lowest rpm allowable to support water surface skimming, vacuuming, SWGs, heater, etc. I'll place a link about pump run time below for your reference. I'll also tag @mas985 for some expert advice on your question specifically.

I suppose this is one of those topics you can experiment with or make things as easy (or difficult) as you wish. Running 24/7 is fine for many, but generally we recommend running pumps on the lowest rpm allowable to support water surface skimming, vacuuming, SWGs, heater, etc. I'll place a link about pump run time below for your reference. I'll also tag @mas985 for some expert advice on your question specifically.

Be sure to update your signatture as that can drive the replies you receive. Also visit our Pool Care Basics page for lots of great info. Enjoy the forum.

www.troublefreepool.com

www.troublefreepool.com

www.troublefreepool.com

www.troublefreepool.com

I suppose this is one of those topics you can experiment with or make things as easy (or difficult) as you wish. Running 24/7 is fine for many, but generally we recommend running pumps on the lowest rpm allowable to support water surface skimming, vacuuming, SWGs, heater, etc. I'll place a link about pump run time below for your reference. I'll also tag @mas985 for some expert advice on your question specifically.

I suppose this is one of those topics you can experiment with or make things as easy (or difficult) as you wish. Running 24/7 is fine for many, but generally we recommend running pumps on the lowest rpm allowable to support water surface skimming, vacuuming, SWGs, heater, etc. I'll place a link about pump run time below for your reference. I'll also tag @mas985 for some expert advice on your question specifically.Be sure to update your signatture as that can drive the replies you receive. Also visit our Pool Care Basics page for lots of great info. Enjoy the forum.

Determine Pump Run Time

To figure out how many hours you need to run your pump, you need to know how fast your pump works. You can find this here.

Create Your Signature - Further Reading

Hootz

Bronze Supporter

- Feb 5, 2018

- 374

- Pool Size

- 24000

- Surface

- Vinyl

- Chlorine

- Salt Water Generator

- SWG Type

- CircuPool RJ-60 Plus

You may be over thinking your pump run schedule. The pump serves to distribute chemicals and skim the surface of debris. If you have a salt water generator that will also determine pump run time. Some can get by with a four hour run every 24 hours. Running the pump for a period long enough to turn over the volume of the pool is not a requirement although you will still hear this advice.

- May 3, 2007

- 16,959

- Pool Size

- 20000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite (T-15)

Yes, as long as the gauge is at the same elevation as the pump.Newbie here - I'm trying to figure out a schedule for my Pentair SuperFlo VSP. The builder set it to run at 2500rpm 24/7 and he told me I can just leave it there, but I want to understand my numbers and fine-tune it anyway. First step for me is to calculate the flow by measuring pressure and vacuum from the ports on my pump. I bought a couple "standard" gauges but the ports on the pump are so low to the ground that I don't have enough room to screw in the gauges. Can I just connect my gauges to a hose and then connect the hose to the pump ports? Will that still give accurate readings?

But you really don't need to know flow rate. Forget everything you were told about turnover. It just isn't relevant.

The setting of RPM should be based upon the task at hand. SWGs, Heaters, Skimmers all have minimum flow rates which is more accurately done by trial and error. Reduce RPM until the SWG alarms, heater alarms and/or water goes around the weir door instead of over it. Then add 200 RPM for margin.

Thread Status

Hello , This thread has been inactive for over 60 days. New postings here are unlikely to be seen or responded to by other members. For better visibility, consider Starting A New Thread.