Just wondering if someone could comment on power usage by a 1hp pump. Theoretically 1hp equals 746 watts, or Joules/s. But it would be interesting to measure the actual current at start up, and while running to calculate the real power usage. Just wondered if someone has done that. I left my clamp on meter in Alaska.

Power used by 1hp pump

- Thread starter mecheng1

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Typically, a 1 hp total hp motor uses about 1,000 watts.

the hp rating is confusing because it is the hp delivered to the water and not the total hp used.

There is also a "Service Factor" on older models that is now mostly gone.

In any case, check the amperage on the label and multiply the volts by the amps to get the watts.

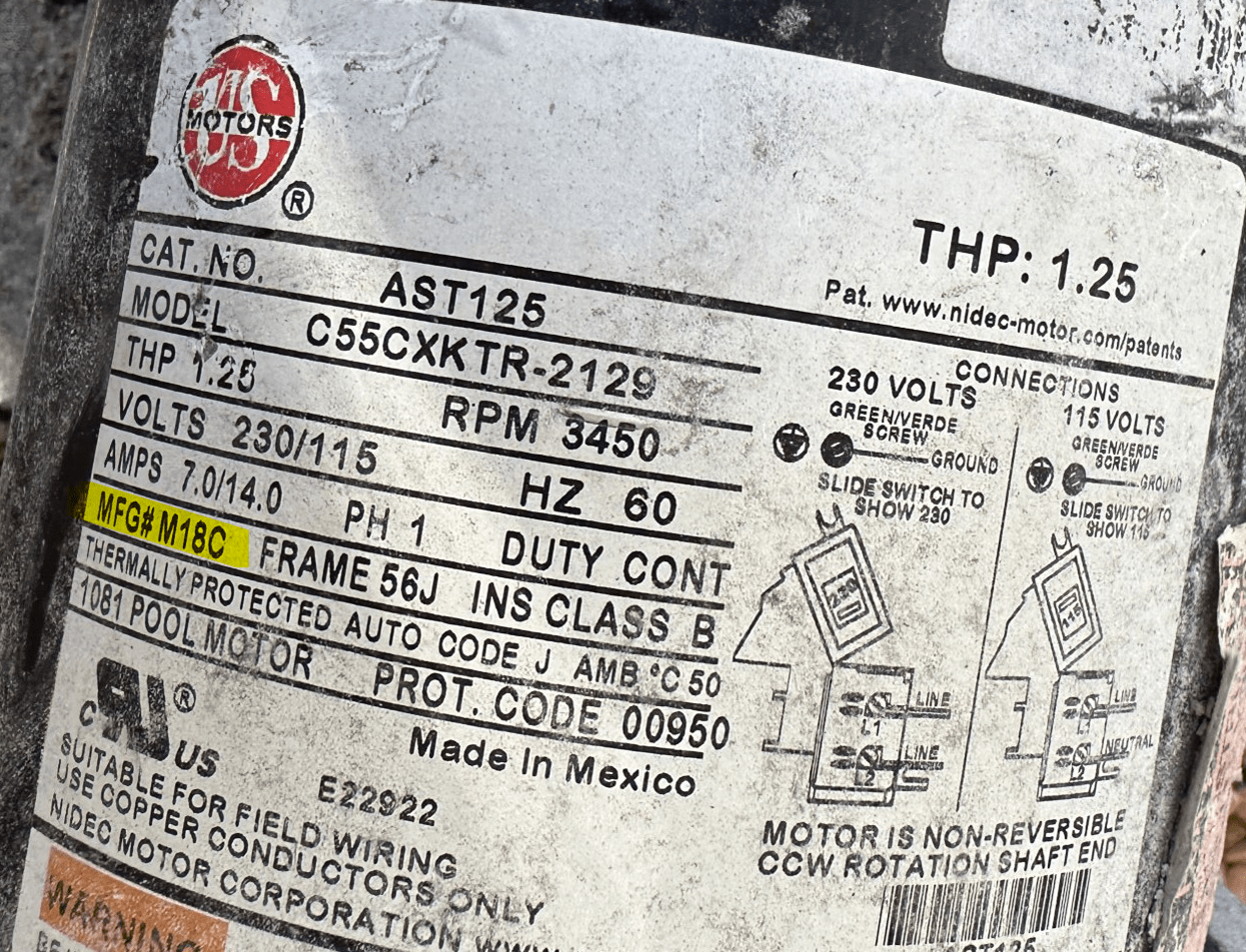

For example, this motor is listed as a 1.25 total hp motor and the wattage comes out to about 1,610 at full maximum load.

230 x 7.0 = 1,610 watts.

For most operations, the actual amperage will be about 75% to 80% of the label listed full load amperage.

230 x 5.43 amps = 1,250 watts.

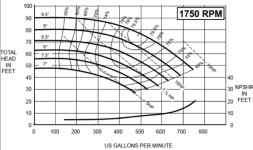

It also depends on the actual impeller.

If you use a smaller impeller, the power draw will be lower.

the hp rating is confusing because it is the hp delivered to the water and not the total hp used.

There is also a "Service Factor" on older models that is now mostly gone.

In any case, check the amperage on the label and multiply the volts by the amps to get the watts.

For example, this motor is listed as a 1.25 total hp motor and the wattage comes out to about 1,610 at full maximum load.

230 x 7.0 = 1,610 watts.

For most operations, the actual amperage will be about 75% to 80% of the label listed full load amperage.

230 x 5.43 amps = 1,250 watts.

It also depends on the actual impeller.

If you use a smaller impeller, the power draw will be lower.

Getting rid of "Service Factor" for motors.

Does service factor have any value? In my opinion, it has no value. In fact, I think that it only causes problems and confusion. The only number that really matters is the Total HP of the motor. Motor makers make two identical motors and label one as 1 hp with a 1.65 service factor and the...

You also have to consider the Power Factor, which describes the Ratio of real power to apparent power.

So, if you just measure the amperage and multiply it by the voltage, you get the apparent power.

However, if you have a power factor of 0.90, then the actual power is 90% of the apparent power.

So, you might 230 x 5.43 amps = 1,250 watts, but you need a meter that can measure power factor or an actual wattmeter to measure real power.

If 1,250 watts is the apparent power and you have a power factor of 90%, then the real power is 1,125 watts.

So, if you just measure the amperage and multiply it by the voltage, you get the apparent power.

However, if you have a power factor of 0.90, then the actual power is 90% of the apparent power.

So, you might 230 x 5.43 amps = 1,250 watts, but you need a meter that can measure power factor or an actual wattmeter to measure real power.

If 1,250 watts is the apparent power and you have a power factor of 90%, then the real power is 1,125 watts.

A good engineer should have at least 3 clamp ammeters.I left my clamp on meter in Alaska.

One as a primary, one as a backup and one as a backup to the backup.

Plus the one you left still connected in Alaska.One as a primary, one as a backup and one as a backup to the backup.

The difference from the total input power to the delivered power is called the Wire-to-Water Efficiency.

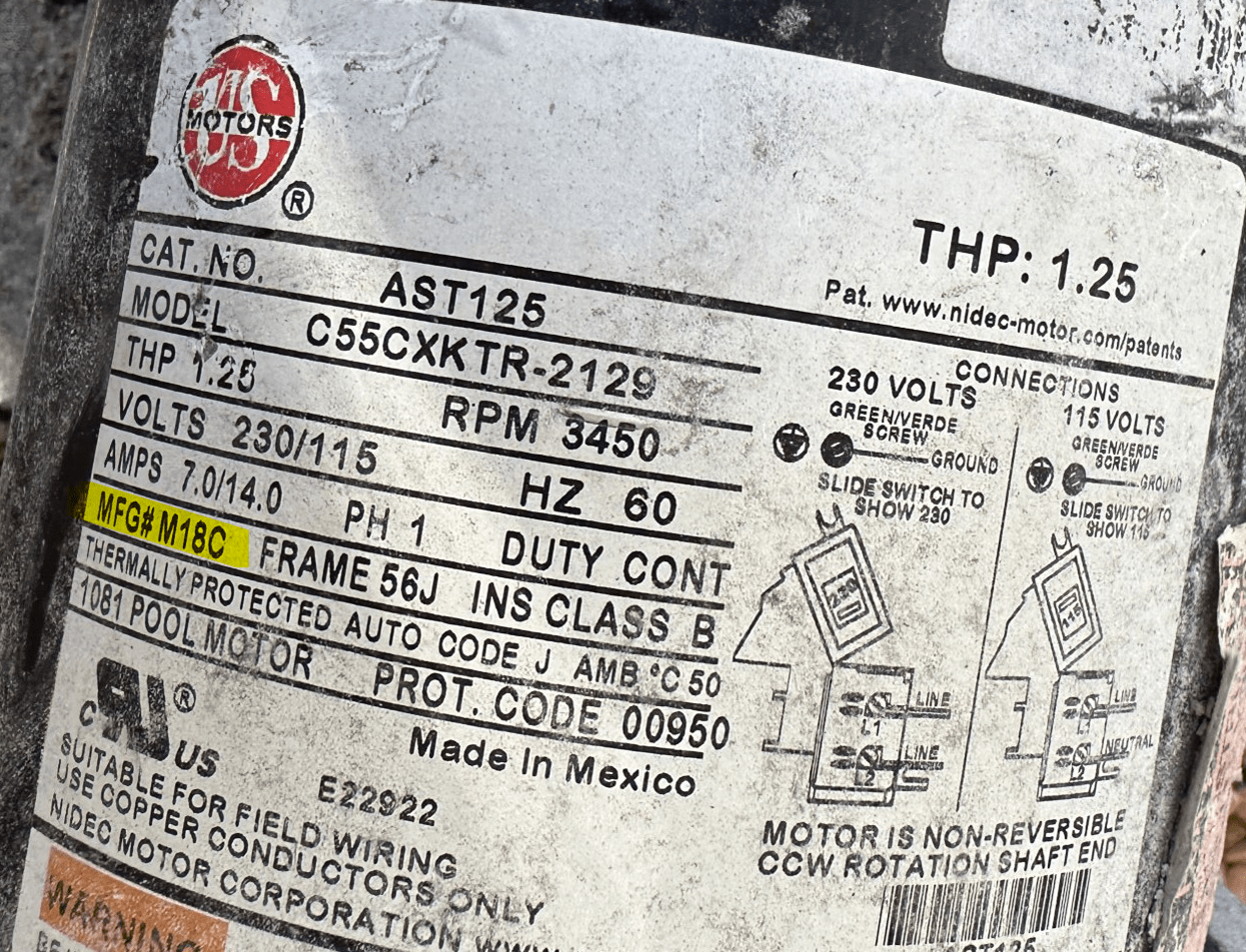

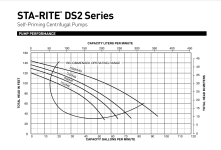

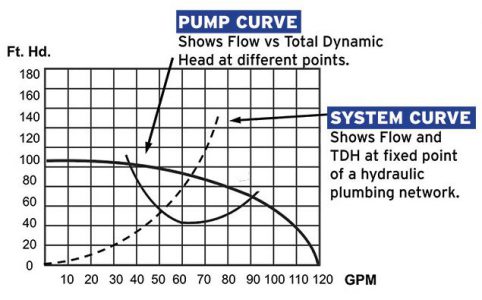

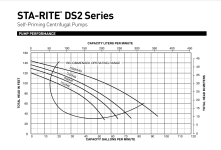

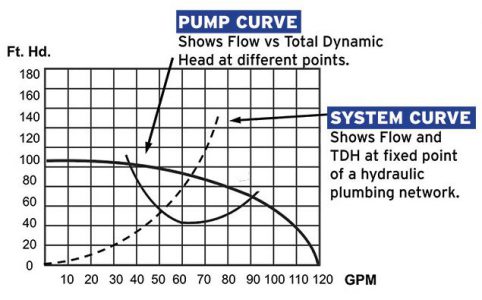

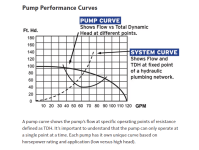

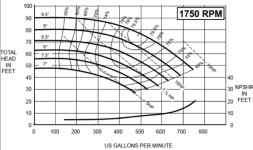

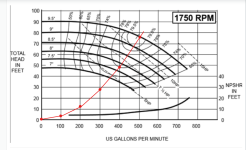

Some pump performance curves will show the efficiency at different operating points.

So, a good pump selection will be where the system curve intersects the pump performance curve at the BEP (Best Efficiency Point).

You can get an idea about the actual power delivered to the water by measuring the flow and the total head loss.

Then you can measure the actual power draw with a wattmeter to see how much actual power is being used compared to the actual useful work being delivered.

So, the answer to your question is not at all straightforward and there are many factors to consider.

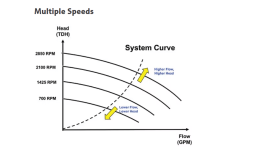

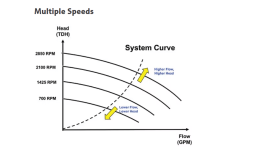

Luckily, most of the issues have been solved with the use of variable speed pumps where you can adjust the speed until it creates the flow that you need for a specific purpose.

This assumes that the builder actually designed the hydraulics correctly to allow efficient operation.

www.inyopools.com

www.inyopools.com

www.aquamagazine.com

www.aquamagazine.com

Some pump performance curves will show the efficiency at different operating points.

So, a good pump selection will be where the system curve intersects the pump performance curve at the BEP (Best Efficiency Point).

You can get an idea about the actual power delivered to the water by measuring the flow and the total head loss.

Then you can measure the actual power draw with a wattmeter to see how much actual power is being used compared to the actual useful work being delivered.

So, the answer to your question is not at all straightforward and there are many factors to consider.

Luckily, most of the issues have been solved with the use of variable speed pumps where you can adjust the speed until it creates the flow that you need for a specific purpose.

This assumes that the builder actually designed the hydraulics correctly to allow efficient operation.

How To Read and Understand A Pool Pump Performance Curve

The way you determine how many gallons per minute your pump pushes is by reviewing the pool pump curve. A pool pump curve is straightforward.

How to Read Pump & System Curves

If you find yourself somewhat mystified by pump curves and performance charts, or if you need to train someone about hydraulic efficiency, here’s a brief primer to get you started.

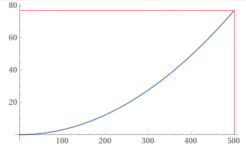

y=0.000308(x)^2, x from 0 to 500 - Wolfram|Alpha

Wolfram|Alpha brings expert-level knowledge and capabilities to the broadest possible range of people—spanning all professions and education levels.

Thread Status

Hello , This thread has been inactive for over 60 days. New postings here are unlikely to be seen or responded to by other members. For better visibility, consider Starting A New Thread.