This is my design for re-plumbing that I need to do. I am looking for comments on any mistakes I’ve made, suggestions for improvement or validation that this is a viable design.

Since I have an in-floor cleaning system, I need to replumb to add a bypass loop for my Pentair IC40 SCG. This is stated in the IC40 installation manual and, because of the in-floor cleaning system, Pentair support let me know that this bypass loop would be absolutely required for any warranty claims I might have in the future.

The current layout has the filter side-by-side with the pump with the outflow pipe connected to the IC40 which in turn is connect to the Jandy. All in a straight line.

Design Notes

Since I have an in-floor cleaning system, I need to replumb to add a bypass loop for my Pentair IC40 SCG. This is stated in the IC40 installation manual and, because of the in-floor cleaning system, Pentair support let me know that this bypass loop would be absolutely required for any warranty claims I might have in the future.

The current layout has the filter side-by-side with the pump with the outflow pipe connected to the IC40 which in turn is connect to the Jandy. All in a straight line.

Design Notes

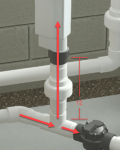

- For the bypass loop design itself, I going with the suggestion from Bama Rambler in this thread: Where Can I Get This Flow Control Valve

- The SCG bypass loop was set on a 45-degree angle since the is not enough room to go straight back from the return Jandy valve.

- There is a 12-inch straight pipe immediately before the IC40 to allow for proper flow sensing.

- There is a 4-inch pipe after the IC40 before the elbow.

- I might need to support the pipe between the 45s. I calculate that there would be 12 lbs of water plus 8 lbs for the IC40 means over 20 lbs. The 45-degree layout for the bypass loop section means that there is no point-to-point beam bridge type support which may apply too much stress to the filter fitting and to the Jandy.

- I might need to support the pipes on the pressure side between the pump and the filter.

- There are a T and spigot located directly above the pump on the pressure side. These are not represented in the picture.

- I will need to replace the existing crumbling concrete pad. In this layout, I might go with two separate pads.