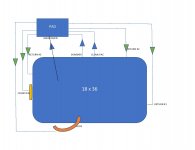

DIY renovation IG 18x36. First time pool owner. Been researching for months. Started our project in April, weekends and evenings. Awesome info on this site and I have really been educated. We built a vinyl over bench (ICF) and corner steps in the shallow end, added dual main drain, repoured the hopper and extended the shallow end 3', new vermic bottom. This is a family project. Nothing like mixing 2 pallets of 60lb premix bags to build character in my 2 teenage girls. One thing they learned real quick, you can't mix and pour concrete with a phone in your hand. They initially complained, but now they tell all their friends what they did. They are looking forward to the next phase of work. Skimmer/line is being replaced and I'm adding one return. It's an extensive renovation that doubles as family time.

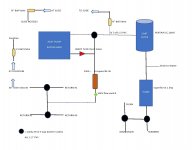

I have drawn up a basic plumbing plan that I would like your observations on. I am planning on implementing all the suggestions, such as pipe length before the pump, use unions before and after components. Sweep 90's instead of street, schedule 40 for all, etc. The purpose of the diagram is to confirm I have all the parts and pieces in the right places. Pad is about a foot below water level, about 15' from pool. Water will be bonded at the skimmer. Did not include zinc anode, I have no metal that needs to be protected. I do want a heater bypass, as I may install the heater next year. Existing slide is 3/4 flex pvc. Fountain will be new install with 1.5 rigid.

2 questions

Do I need a pressure relief valve after the heater and before the CV?

I'm thinking of doing 2" at the pad, even though all underground is 1.5 rigid. I would start the 2" from the 3way into the pump. Transition back to 1.5 at the first return 3 way. I'm doing this more for consistency and ease of plumbing, rather than efficiency or GPMs. Are there any obvious issues I will run into going 2" at the pad?

Thanks for your observations!

I have drawn up a basic plumbing plan that I would like your observations on. I am planning on implementing all the suggestions, such as pipe length before the pump, use unions before and after components. Sweep 90's instead of street, schedule 40 for all, etc. The purpose of the diagram is to confirm I have all the parts and pieces in the right places. Pad is about a foot below water level, about 15' from pool. Water will be bonded at the skimmer. Did not include zinc anode, I have no metal that needs to be protected. I do want a heater bypass, as I may install the heater next year. Existing slide is 3/4 flex pvc. Fountain will be new install with 1.5 rigid.

2 questions

Do I need a pressure relief valve after the heater and before the CV?

I'm thinking of doing 2" at the pad, even though all underground is 1.5 rigid. I would start the 2" from the 3way into the pump. Transition back to 1.5 at the first return 3 way. I'm doing this more for consistency and ease of plumbing, rather than efficiency or GPMs. Are there any obvious issues I will run into going 2" at the pad?

Thanks for your observations!