Hello,

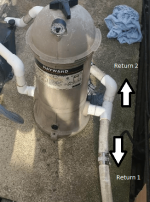

I plan on doing a bit of a plumbing overhaul at some point with a new filter and maybe SWG. When I do this, I want to take care of how to both blowout and add antifreeze to my two return lines for winter closing. Currently it is a giant pain and I feel as if I'm tearing up the plumbing doing it. The plumbing to the return lines is not very good, and there is soft PVC piping with soft clamps that I take off to blowout/add antifreeze:

My question is what kind of plumbing do most people have to easily blowout the return lines/add antifreeze?

My current thought is to replace the soft PVC piping with hard PVC and add a cleanout valve to each return line. However I'm not sure if cleanout valves hold well under the pump's pressure (don't leak)?

I'm also thinking of adding a shutoff valve before the return lines

What are your guys thoughts?

Thanks

I plan on doing a bit of a plumbing overhaul at some point with a new filter and maybe SWG. When I do this, I want to take care of how to both blowout and add antifreeze to my two return lines for winter closing. Currently it is a giant pain and I feel as if I'm tearing up the plumbing doing it. The plumbing to the return lines is not very good, and there is soft PVC piping with soft clamps that I take off to blowout/add antifreeze:

My question is what kind of plumbing do most people have to easily blowout the return lines/add antifreeze?

My current thought is to replace the soft PVC piping with hard PVC and add a cleanout valve to each return line. However I'm not sure if cleanout valves hold well under the pump's pressure (don't leak)?

I'm also thinking of adding a shutoff valve before the return lines

What are your guys thoughts?

Thanks