- Nov 12, 2017

- 11,874

- Pool Size

- 12300

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-40

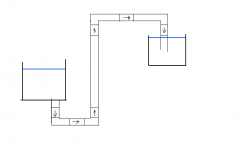

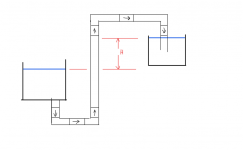

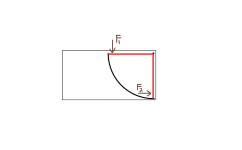

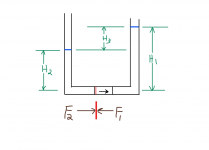

That's very interesting. The "wrong" diagrams in the second chart are wrong because the check valve would stop the intended flow completely, and only allow the unwanted backflow. The "wrong" diagrams in the first chart will allow intended flow, but might fail stopping backflow if the spring fails. So what was Jandy really trying to warn against?It is interesting that Jandy has two different check valve Installation documents with different diagrams...

View attachment 467462

The RIGHT diagrams agree but the WRONG diagrams are different.

All I know for sure is that both of mine are horizontal, with the clear face facing up, and the flapper on the correct side (flow-wise). They'll work with or without the spring.