Any comments on the equipment list (this is what Wholesale Pool Equipment Spec'd out)? Are these the model numbers I should get?

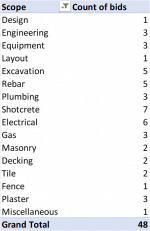

| Item Detail | Quantity |

| 1 | Pentair Trade Grade 011075 3HP 230V Intelliflo3 VSF Pump | 1 |

| 2 | Pentair Trade Grade 160301 Clean and Clear Plus 420 Cartridge Filter | 1 |

| 3 | Pentair 521910 IntelliCenter i8P Single Body Personality Kit | 1 |

| 4 | Pentair Trade Grade 522041 IntelliCenter Load Center W/ SCG Support | 1 |

| 5 | Pentair Trade Grade 521105 Intellichlor Salt Chlorinator IC60 with 15 ft Cord | 1 |

| 6 | Pentair 520588 IntelliChlor Pass-Through Cell | 1 |

| 7 | Pentair 520670 IntelliChlor Acid Washing Kit | 1 |

| 9 | Pentair Trade Grade 521485 IntelliValve Valve Actuator for 2 and 3 Way Valves | 1 |

| 8 | Pentair 263026 Three-way Diverter Valve 2" - 2.50" 3-Port CPVC Diverter Valve | 3 |

| 11 | Pentair 263038 Diverter Valve Two Port 1.50" - 2" | 9 |

| 12 | Pentair 263060 Check Diverter Valve with 2-1/2in. CPVC Pipe | 1 |

| 10 | Pentair Trade Grade 620425 12V 100' Color MicroBrite LED Light | 4 |

| 13 | Pentair 619963 300 Watt Transformer | 1 |

| 14 | Pentair 542464 QuikWater Water Leveler Tan | 1 |

| 15 | Wilkins 12-720A .50" Pressure Vacuum Breaker Assembly | 1 |

| 16 | CMP 25555-001-000 Return Fitting Gray | 7 |

| 17 | Waterway 540-6707 Volleyball / Umbrella Pole 1.5 | 1 |

| 18 | QUIKSKIM GRY/ TAN LID VENTURI SKIMMER W/ FOAM | 2 |

| 19 | Perma Cast PB-2008 Water Bonding Fitting 1 | 1 |

| 20 | Diversitech 2436-3 CladLite Concrete Equipment Pad 24 x 36 x 3 Gray | 1 |

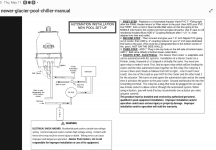

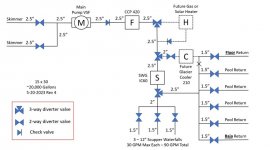

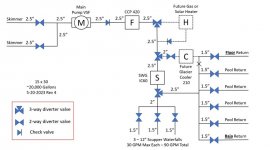

How about the plumbing diagram?

Note all skimmer runs and returns are home runs to the equipment pad and there is one pipe run to the scuppers that will split with three valves right behind the elevated wall.

Several have said I can reduce the pipe sizes so take a look at the design above and let me know if this looks good. For the scuppers they can run up to 90 gpm total so I was thinking a 2" run to where they split into 3 and use 1.5" to each scupper individually. I decided to keep the skimmers at 2.5" so if one is out of commission, I could still get 90 gpm through the other one. I was keeping everything at the pad at 2.5", but wondering if it could/should all be 2" after the pump. Hoping

@JamesW or

@mas985 can take a quick look and be kind enough to give me their thoughts.

Size.......6 ft/sec......8 ft/sec.

1.5"...........38...............51 gpm

2"..............63...............84 gpm

2.5............90.............119 gpm

3.0".........138............184 gpm

4.0"........238.............317 gpm

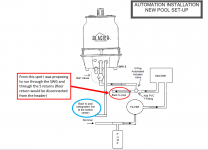

Also, I decided to eliminate the water feature pump and the main drain. However, I'm trying to understand how I will control the scuppers with the three-way valve (will have an actuator) that is between the returns and the scuppers. I believe the intellivalve actuator can only have two setpoints (end points), so one would be 100% returns and the other would either be 100% scuppers or some other setting achieving a % split between the returns and scuppers. The volume of water over the scuppers would then be driven by the pump. Do I have this right? The Wholesale Pool Equipment supplier said the intellivalve actuator is adjustable in 3.75% increments throughout it's range by the intellicenter. I thought I read around here somewhere you are limited to setting it to two positions and that is what it seems to say in the manual. Can someone clarify this for me?

Finally, after talking with a few folks, they said the SWG should be right before the returns and after the chiller. This is because most of the flow will go to the pool through the SWG and the 5 returns. Just enough of the flow will go through the chiller so the wand "walks" at the right speed which then sends the cooled water to pool through the one floor return.